Upper punching structure for continuous deep drawing or molding die

A forming mold and stretching forming technology, which is applied in the direction of perforating tools, manufacturing tools, metal processing equipment, etc., can solve the problems of unstable difficulty, affecting the normal operation of the mold, increased stretching or forming, etc., to achieve guaranteed strength and effective compression The effect of material area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

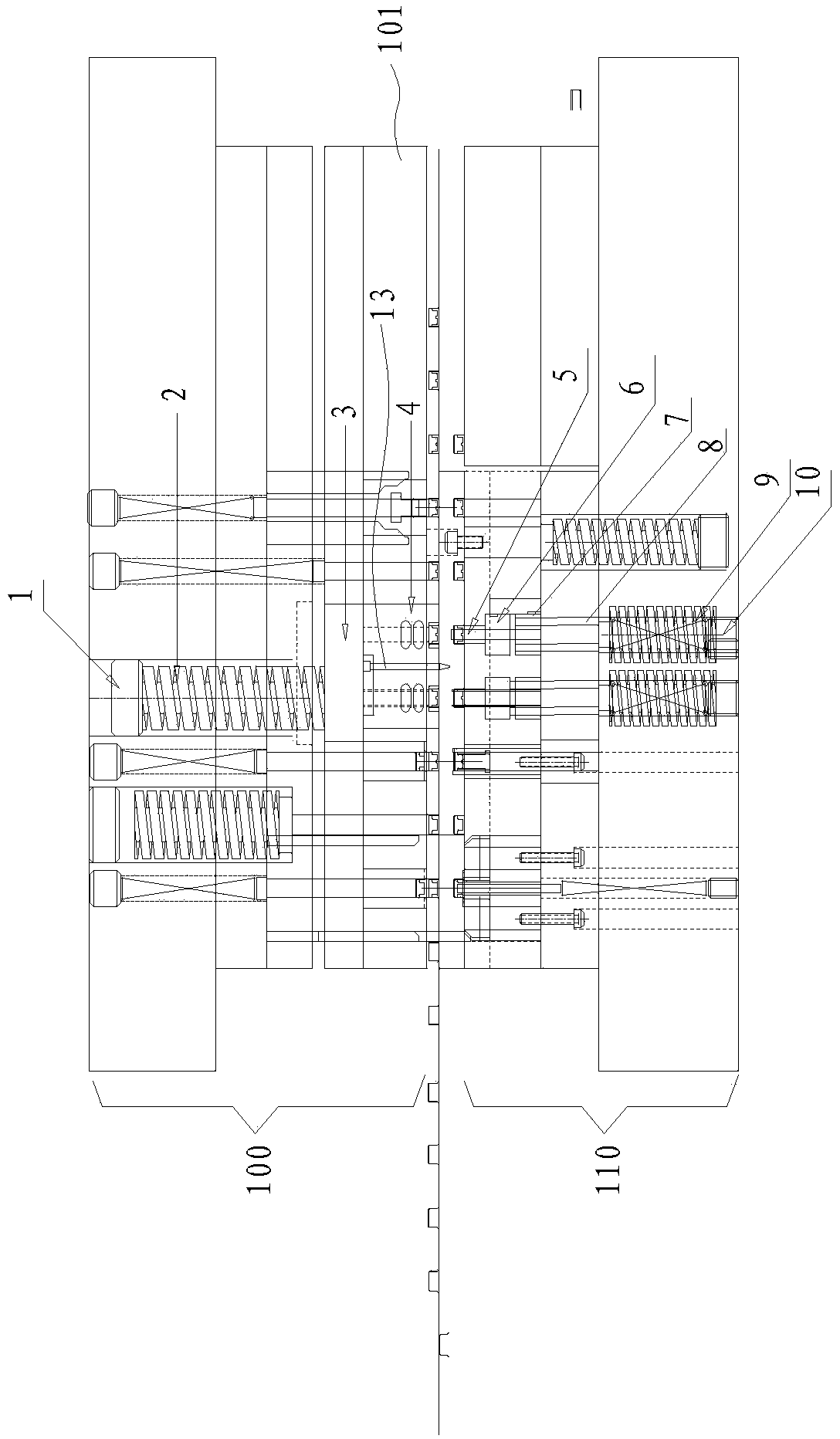

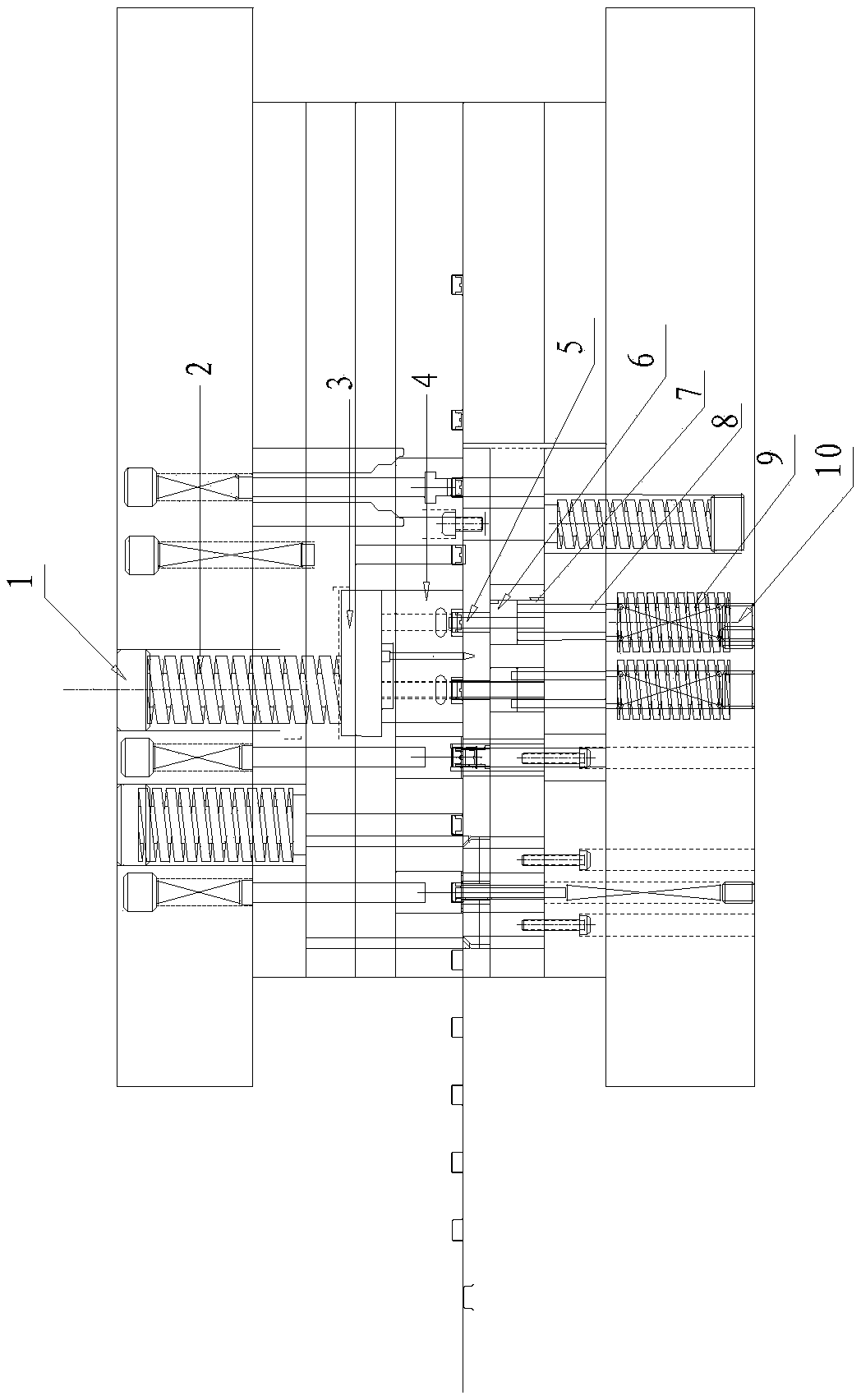

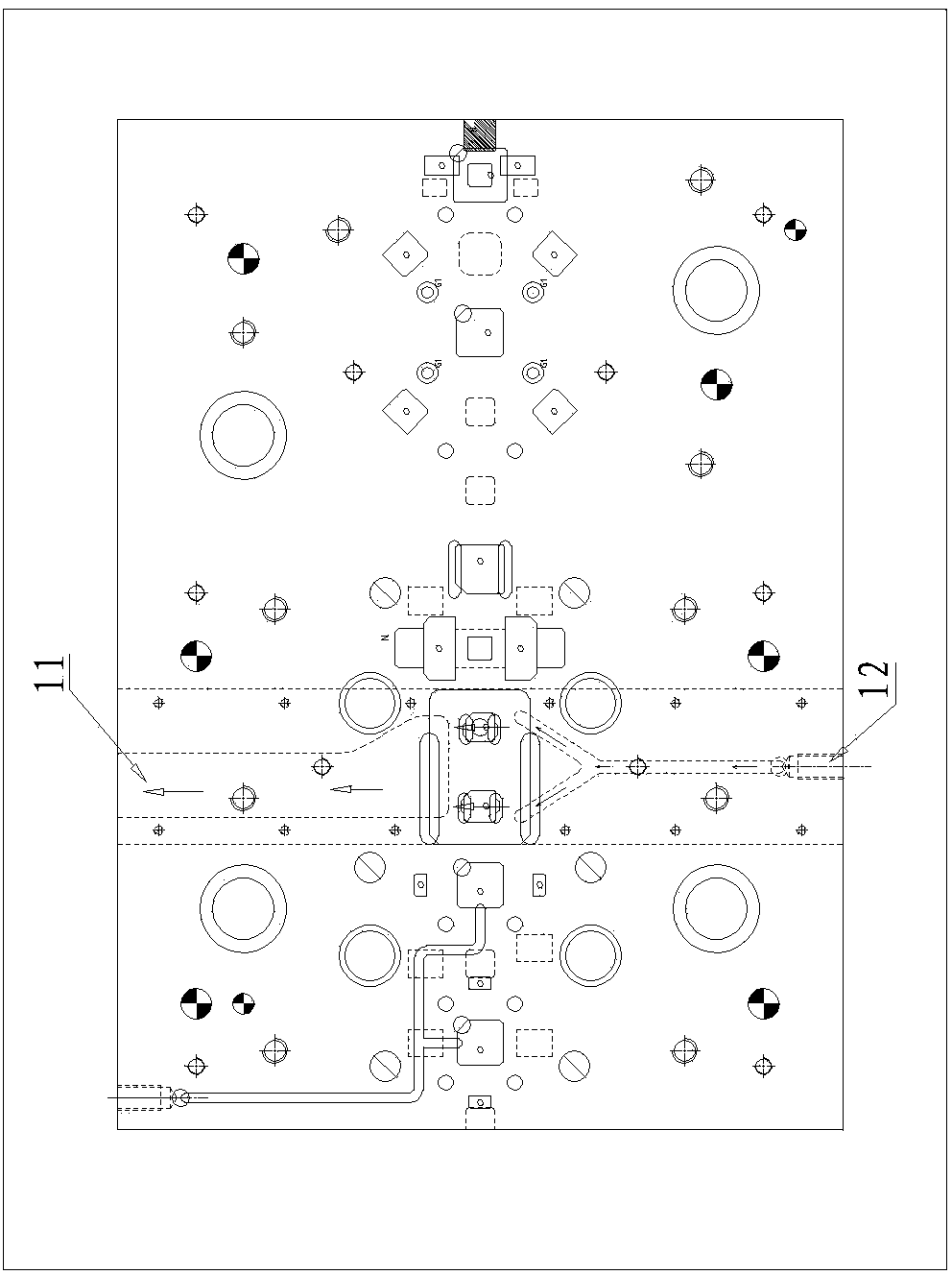

[0020] Example: see Figure 1 to Figure 3 , an upper punching structure for continuous drawing or forming moulds, comprising a stretch forming upper die 100 and a stretch forming lower die 110, a punching punch 5 is installed on the stretch forming lower die 110, and a stretch forming upper die 100 The punching die 4 corresponding to the punching punch 5 is installed, and the stretch forming lower die 110 is provided with a punching and stripping block 6 and is passed through by the punching punch 5, and the punching and stripping block 6 is formed by a stripping spring 9 is lifted by the power transmission pin 8, and the punching and stripping block 6 is pressed down by the punching die 4 when the mold is closed, so that the punching punch 5 protrudes and cooperates with each other to complete the upper punching operation after stretching and forming. A blowing passage is provided between the upper and lower molding dies, and the passage communicates with the punching die cav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com