Ultrafine maize straw grinding device

A technology for ultra-fine pulverization and corn stalks, which is applied in the direction of grain processing, etc., can solve the problems of low fine pulverization effect, inability to meet the requirements of fineness and yield of corn stalk bio-accessibility, and inability to achieve secondary processing in coarse pulverization. , to achieve the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

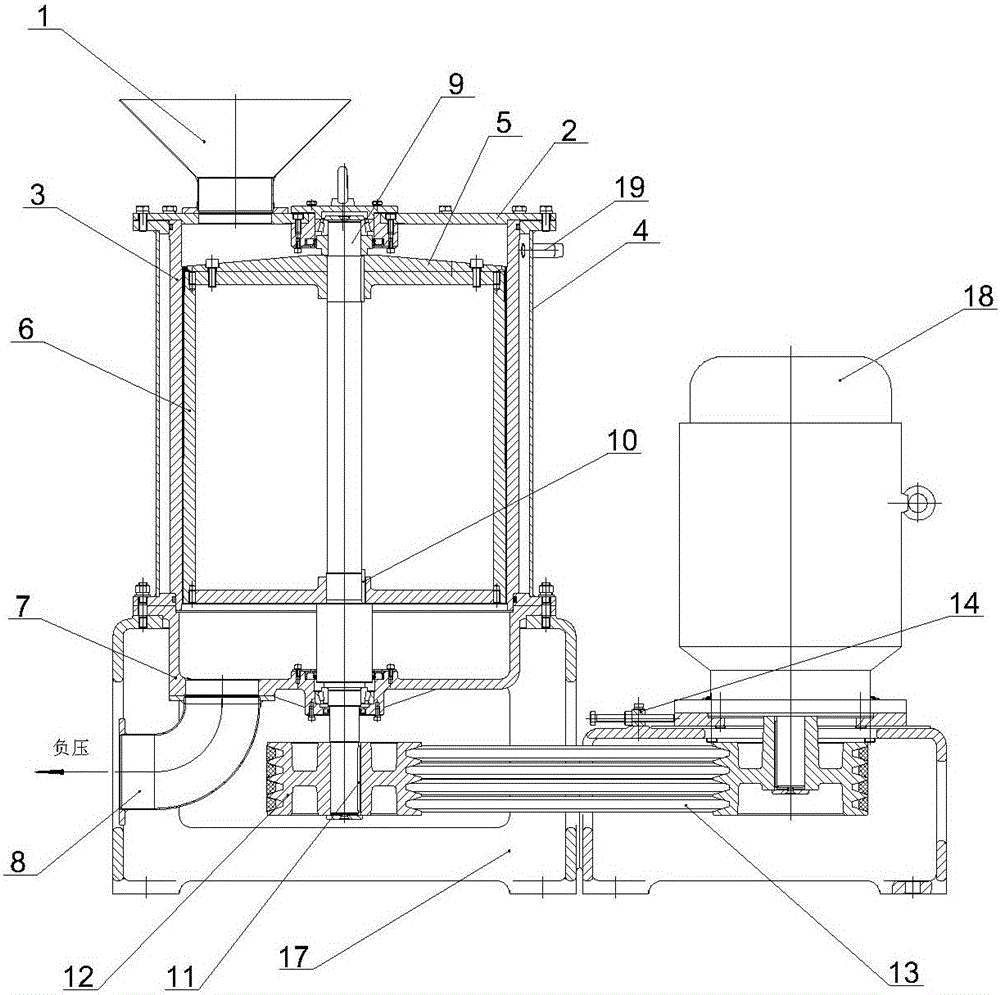

[0020] figure 1 It is a structural representation of the present invention. The present invention includes a frame 17 on which a crushing assembly and a motor assembly 18 are fixed. The motor assembly 18 is connected with the crushing assembly through a transmission assembly.

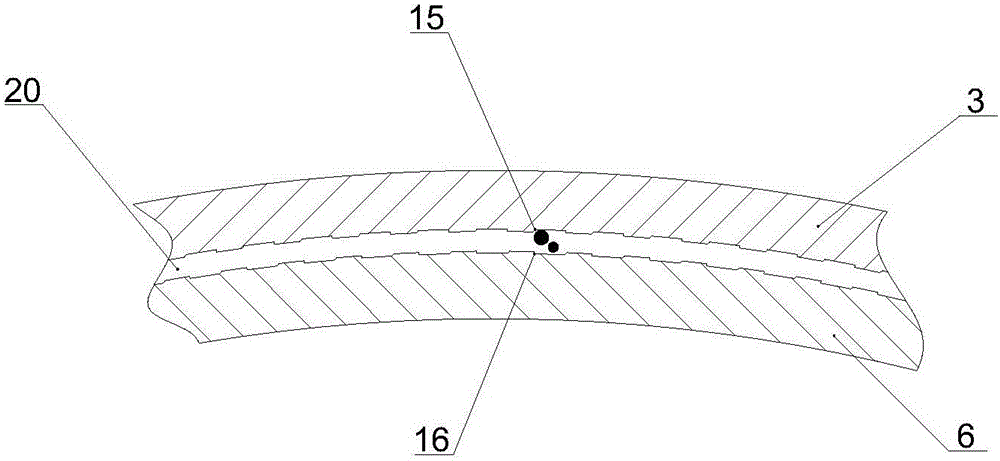

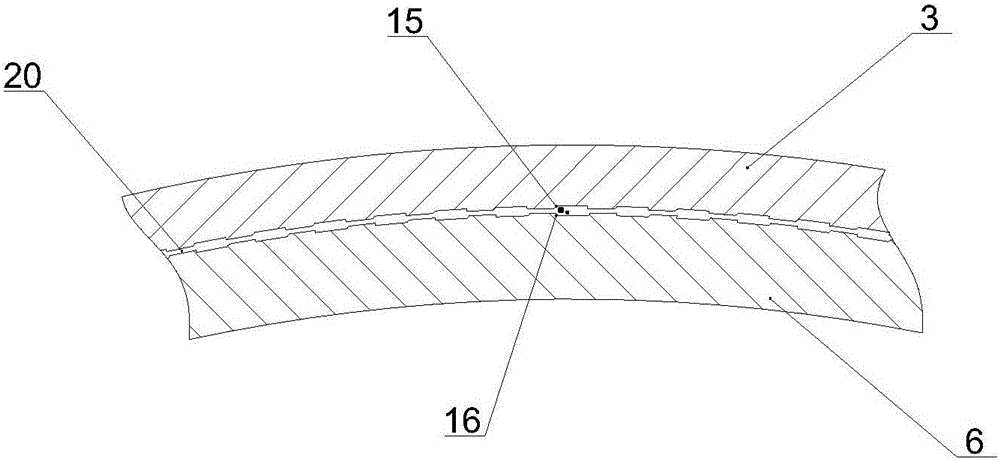

[0021] The crushing assembly includes a cylindrical dynamic grinding sleeve 6 and a fixed grinding sleeve 3 . The fixed grinding cover 3 is fixed on the frame 17, the upper end of the fixed grinding cover 3 is fixed with loam cake 2, and the lower end is fixed with lower feed bin 7. A hopper 1 is fixed on the upper cover 2 . A discharge pipe 8 is fixed under the lower feed bin 7 . The discharge pipe 8 is provided with a negative pressure device, which can suck out the material in the lower silo 7 .

[0022] The movable grinding sleeve 6 and the fixed grinding sleeve 3 are cylindrical, and are coaxially installed with the rotating shaft 9 as the axis.

[0023] The movable grinding sleeve 6 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com