A kind of preparation method of ultrafine lignin

A lignin and ultra-fine technology, applied in the field of preparation of ultra-fine lignin, can solve the problems of low production efficiency and high cost, and achieve the effects of improving production efficiency, improving performance and satisfying market demand.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Step (1): 120-mesh lignin and 325-mesh grinding aid aluminum hydroxide are mixed and stirred evenly in a weight ratio of 30:5;

[0032] Step (2): The mixture obtained in step (1) and 0.8MPa compressed air are simultaneously injected into the jet mill to obtain pulverized materials;

[0033] Step (3): Putting the pulverized material obtained in step (2) into a classifier or a classifying chamber for classifying, the classifying speed is 8000r / min, and the classified particles are obtained;

[0034] Step (4): For the classified particles obtained in step (3), return the particles with a particle size of <4000 mesh to the airflow mill for re-grinding, and discharge the particles with a particle size of ≥4000 mesh from the discharge port, which is the ultrafine Lignin.

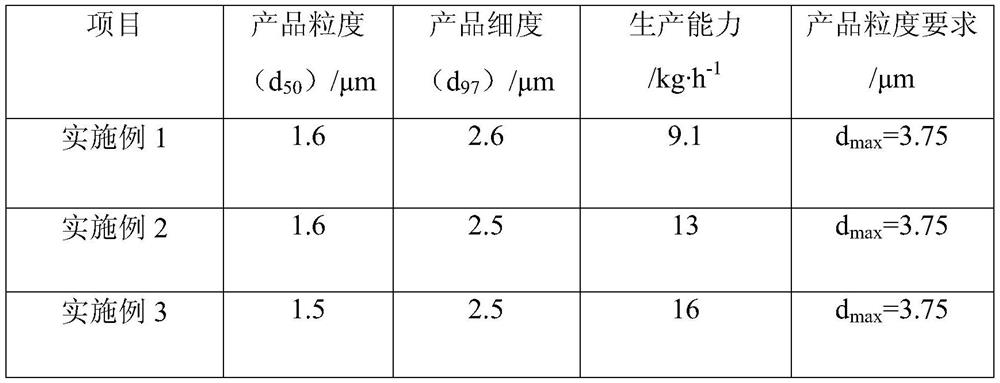

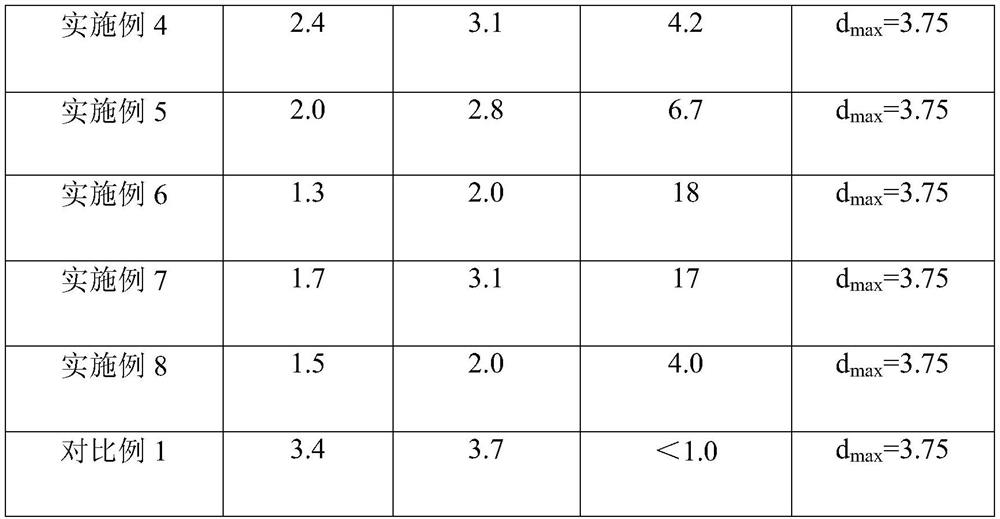

[0035] Various parameters for preparing ultrafine lignin are shown in Table 1.

Embodiment 2

[0037] Step (1): 120-mesh lignin and 325-mesh grinding aid aluminum hydroxide are mixed and stirred evenly in a weight ratio of 20:5;

[0038] Step (2): The mixture obtained in step (1) and 0.8MPa compressed air are simultaneously injected into the jet mill to obtain pulverized materials;

[0039] Step (3): Putting the pulverized material obtained in step (2) into a classifier or a classifying chamber for classifying, the classifying speed is 8000r / min, and the classified particles are obtained;

[0040] Step (4): For the classified particles obtained in step (3), return the particles with a particle size of <4000 mesh to the airflow mill for re-grinding, and discharge the particles with a particle size of ≥4000 mesh from the discharge port, which is the ultrafine Lignin.

[0041] Various parameters for preparing ultrafine lignin are shown in Table 1.

Embodiment 3

[0043] Step (1): 120-mesh lignin and 325-mesh grinding aid aluminum hydroxide are mixed and stirred evenly in a weight ratio of 10:5;

[0044] Step (2): The mixture obtained in step (1) and 0.8MPa compressed air are simultaneously injected into the jet mill to obtain pulverized materials;

[0045] Step (3): Putting the pulverized material obtained in step (2) into a classifier or a classifying chamber for classifying, the classifying speed is 8000r / min, and the classified particles are obtained;

[0046] Step (4): For the classified particles obtained in step (3), return the particles with a particle size of <4000 mesh to the airflow mill for re-grinding, and discharge the particles with a particle size of ≥4000 mesh from the discharge port, which is the ultrafine Lignin.

[0047] Various parameters for preparing ultrafine lignin are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com