Preparation method of traditional Chinese medicine superfine powder decoction piece

A technology of ultra-fine powder and decoction pieces, which is applied in the direction of pharmaceutical formula, medical preparations containing active ingredients, powder delivery, etc. It can solve the problems of unsatisfactory dissolution of active substances and limited effect of cell wall fragmentation, so as to improve bioavailability and reduce loss , Improve the effect of dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

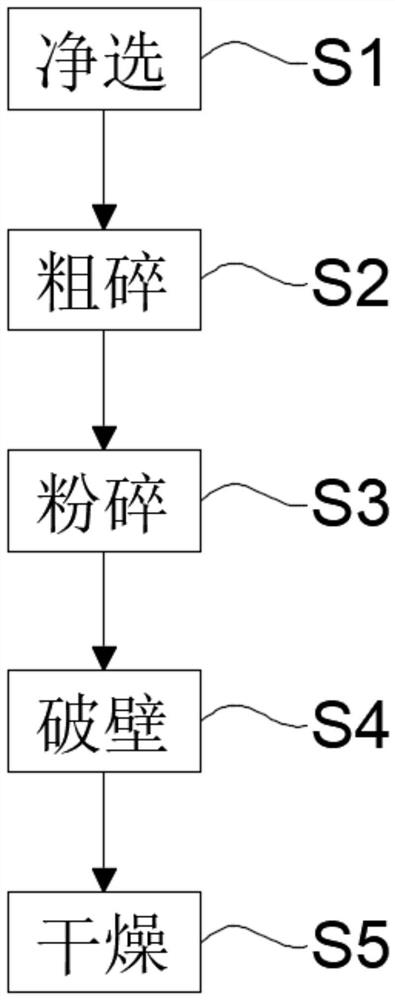

[0021] The preparation method of Radix Notoginseng ultrafine powder decoction pieces, comprises the steps:

[0022] S1. Take 5Kg Panax notoginseng medicinal material, remove impurities such as moldy products and non-medicinal parts in the medicinal material, wash with water to see the true color of the medicinal material Panax notoginseng, and dry the surface moisture of the medicinal material;

[0023] S2, using a universal pulverizer to crush the cleaned notoginseng medicinal material into 1.5mm notoginseng medicinal material particles;

[0024] S3. Add 0.1 times the amount (w / w) of water to the notoginseng medicinal material particles obtained in step 2, soak for 0.5 hours to obtain a notoginseng medicinal material particle suspension, and use a colloid mill to pulverize the notoginseng medicinal material particle suspension into a uniform Panax notoginseng medicinal pulp;

[0025] S4. Pump the medicinal material slurry obtained in step 3 into an insulated tank with stirri...

Embodiment 2

[0028] The preparation method of Radix Notoginseng ultrafine powder decoction pieces, comprises the steps:

[0029] S1. Take 5Kg Panax notoginseng medicinal material, remove impurities such as moldy products and non-medicinal parts in the medicinal material, wash with water to see the true color of the medicinal material Panax notoginseng, and dry the surface moisture of the medicinal material;

[0030] S2, using a universal pulverizer to crush the cleaned notoginseng medicinal material into 2mm notoginseng medicinal material particles;

[0031] S3. Add 2 times the amount (w / w) of water to the notoginseng medicinal material particles obtained in step 2, soak for 1.5 hours to obtain a notoginseng medicinal material particle suspension, and use a colloid mill to pulverize the notoginseng medicinal material particle suspension into a uniform Panax notoginseng medicinal pulp;

[0032] S4. Pump the medicinal material slurry obtained in step 3 into an insulated tank with stirring, ...

Embodiment 3

[0035] The preparation method of Radix Notoginseng ultrafine powder decoction pieces, comprises the steps:

[0036] S1. Take 5Kg Panax notoginseng medicinal material, remove impurities such as moldy products and non-medicinal parts in the medicinal material, wash with water to see the true color of the medicinal material Panax notoginseng, and dry the surface moisture of the medicinal material;

[0037] S2, using a universal pulverizer to crush the cleaned notoginseng medicinal material into 2.5mm notoginseng medicinal material particles;

[0038] S3. Add 4 times the amount (w / w) of water to the notoginseng medicinal material particles obtained in step 2, soak for 2 hours to obtain a notoginseng medicinal material particle suspension, and use a colloid mill to pulverize the notoginseng medicinal material particle suspension into a uniform Panax notoginseng medicinal pulp;

[0039] S4. Pump the medicinal material slurry obtained in step 3 into an insulated tank with stirring, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com