Natural rubber primary processing wet stirring and extrusion washing all-in-one machine

A natural rubber, primary processing technology, applied in grain processing, etc., can solve problems such as wear or damage of single-screw extrusion washing machine, increase in the number of production process line equipment, and small screw pitch of pushing material, so as to reduce intermediate equipment and investment Cost, the effect of reducing the number of units

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

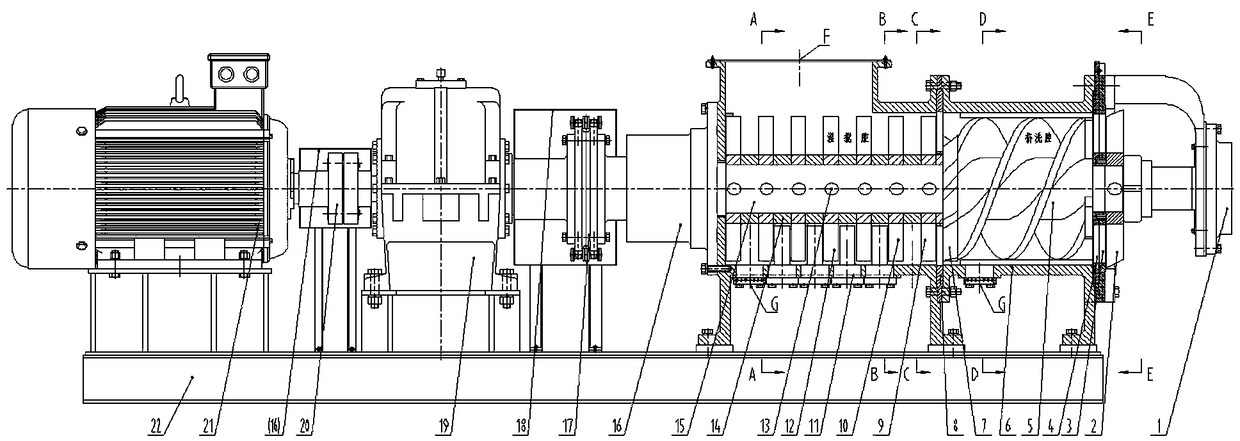

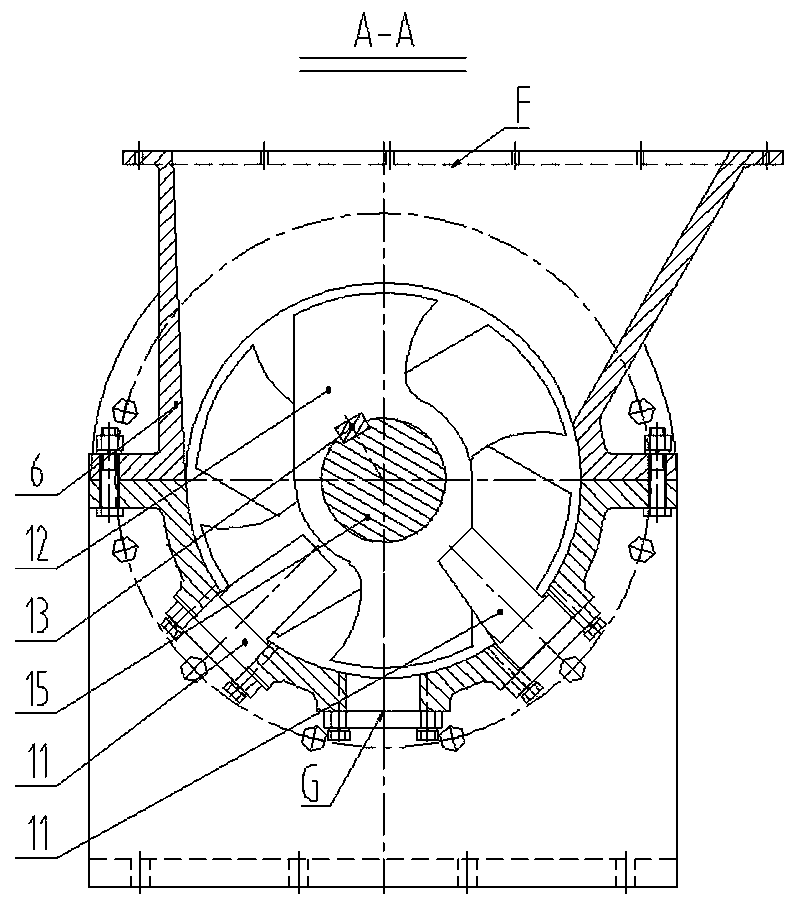

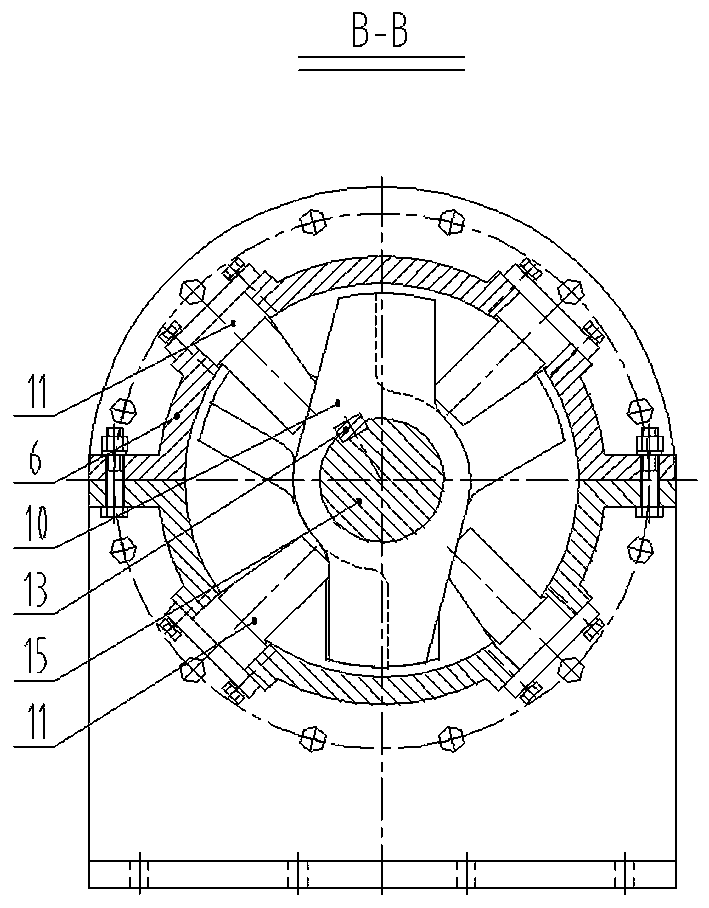

[0039] It includes a base (22), a small coupling (20) is installed between the motor (21) and the input shaft of the reducer (19), and a large coupling (17) is installed at the output shaft end of the reducer (19) , the torque generated by the motor (21) is transmitted to the main shaft (15) through the large coupling (17), and at the same time the speed is decelerated to the design requirements. For safety reasons, the large coupling (17) and the small coupling ( 20) A protective cover (18) is installed on the outside; the motor (21), the reducer (19), the protective cover (18), and the main engine casing (6) are fixed on the base (22) through bolt connection.

[0040] The main shaft (15) is installed inside the main engine casing (6), the tail bearing seat (1) and the head bearing seat (16) are installed at both ends of the main engine casing (6), and they are connected with the main engine casing (6) by bolts Fixed as one, bearings are installed inside the tail bearing seat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com