Preparation equipment for metallic nano powder and use method of preparation equipment

A metal nanopowder and equipment technology, applied in metal processing equipment, nanotechnology, transportation and packaging, etc., can solve the problems of narrow particle size distribution of metal nanopowder and pollution of nanomaterials, and achieve fewer moving parts and good reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Exemplary embodiments, features, and aspects of the present invention will be described in detail below with reference to the accompanying drawings. The same reference numerals in the figures denote functionally identical or similar parts. While various aspects of the embodiments are shown in drawings, the drawings are not necessarily drawn to scale unless specifically indicated.

[0048] For those skilled in the art, it should be clear that the direction words such as "front, back, up, down, left, right" mentioned in this application are only for explaining the present invention more intuitively, so the above-mentioned words in the text The words used in the direction do not constitute a limitation on the protection scope of the present invention.

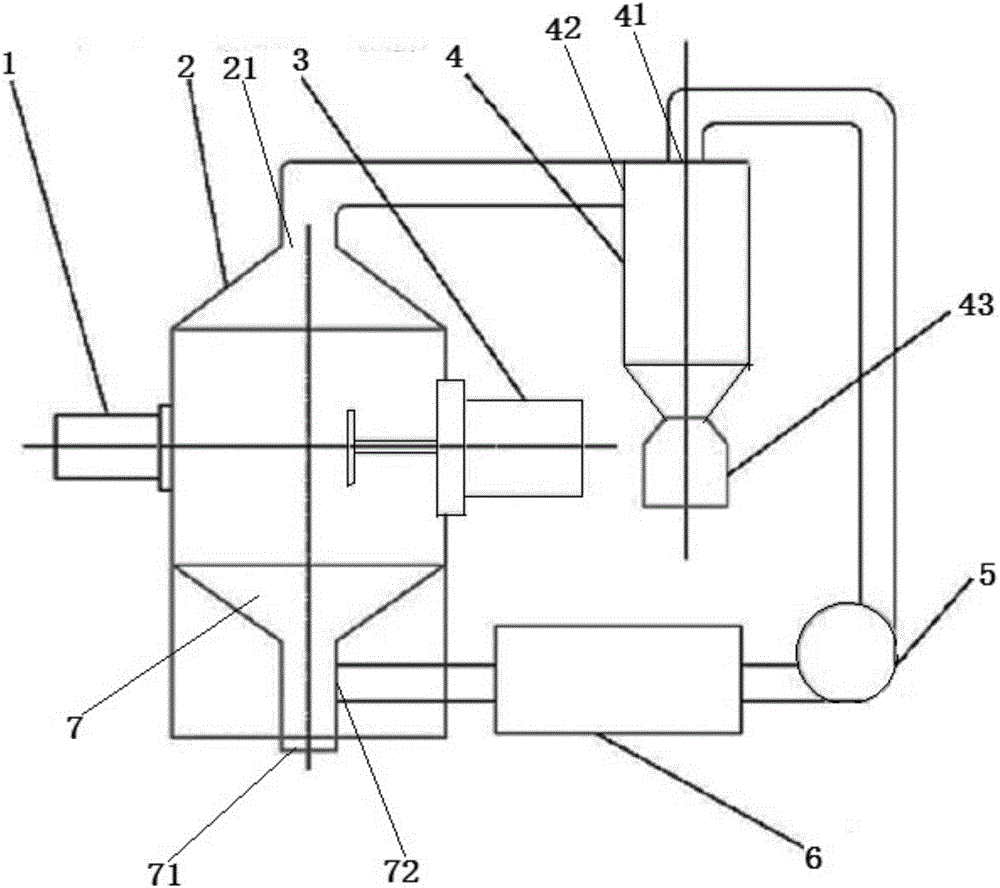

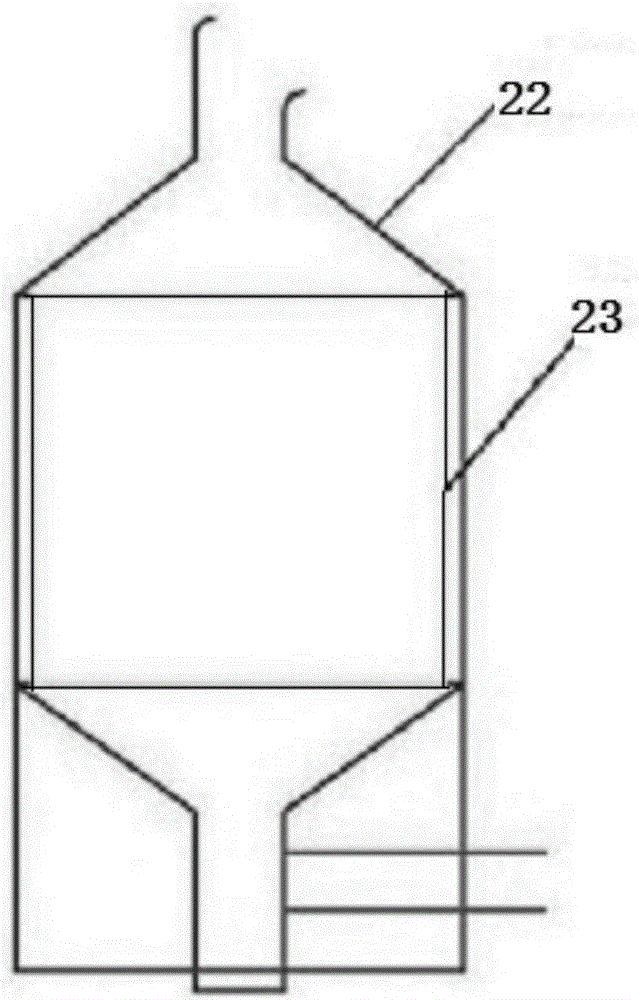

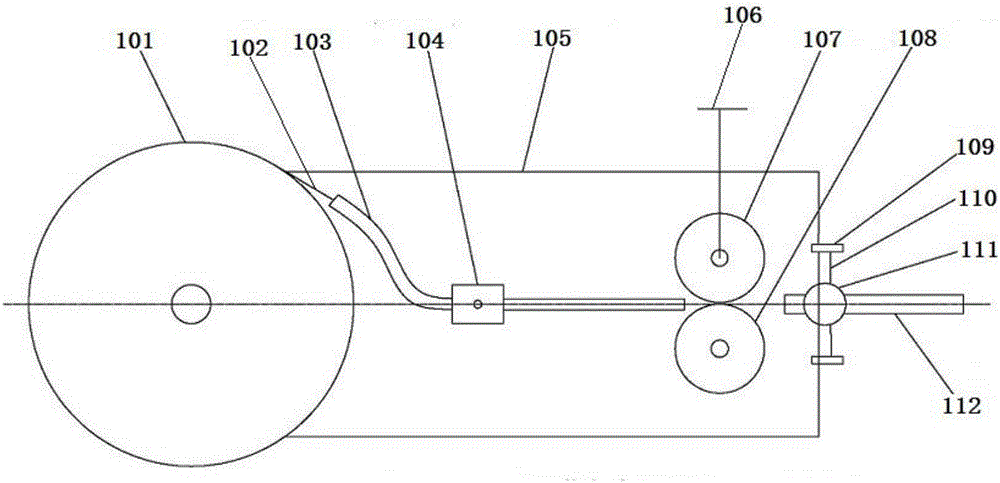

[0049] Such as Figure 1 to Figure 4 As shown, a metal nanopowder preparation equipment includes a feeding mechanism 1, a reactor 2, a high-pressure generator 3, a cyclone collector 4, a high-pressure fan 5, a cooler 6 an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com