Automatic modularized turning assembly line

An automatic assembly line and modular technology, applied in metal processing and other directions, can solve the problems of difficulty in fully liberating production labor, staying in the manual stage, lack of organic connections, etc., to improve labor production efficiency, reasonable structure and accurate positioning. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

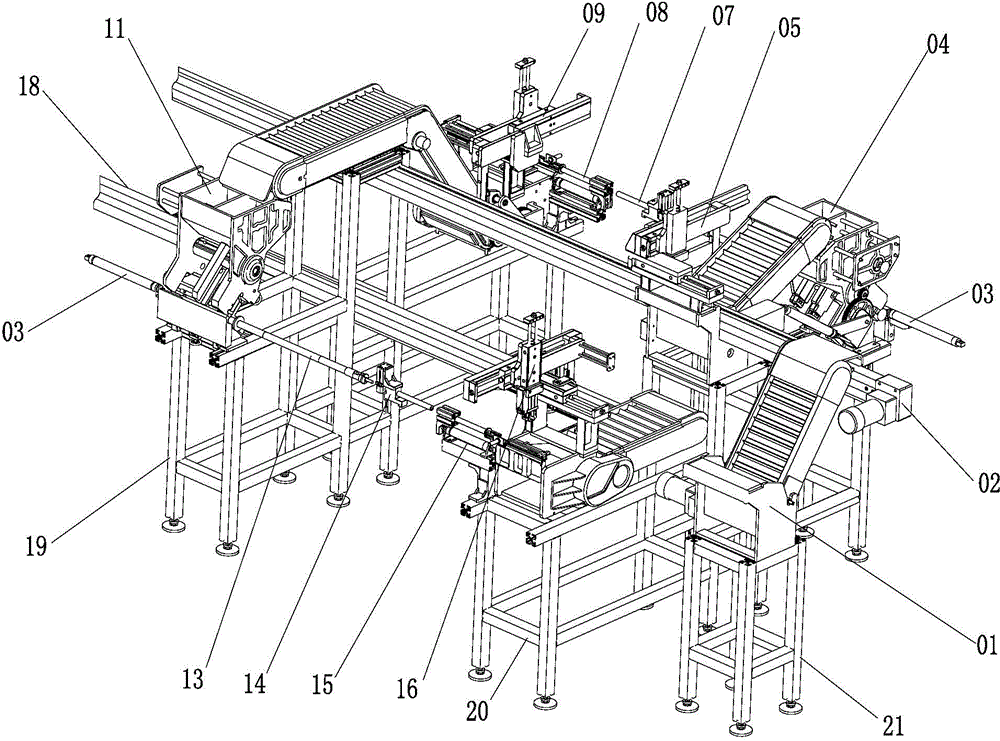

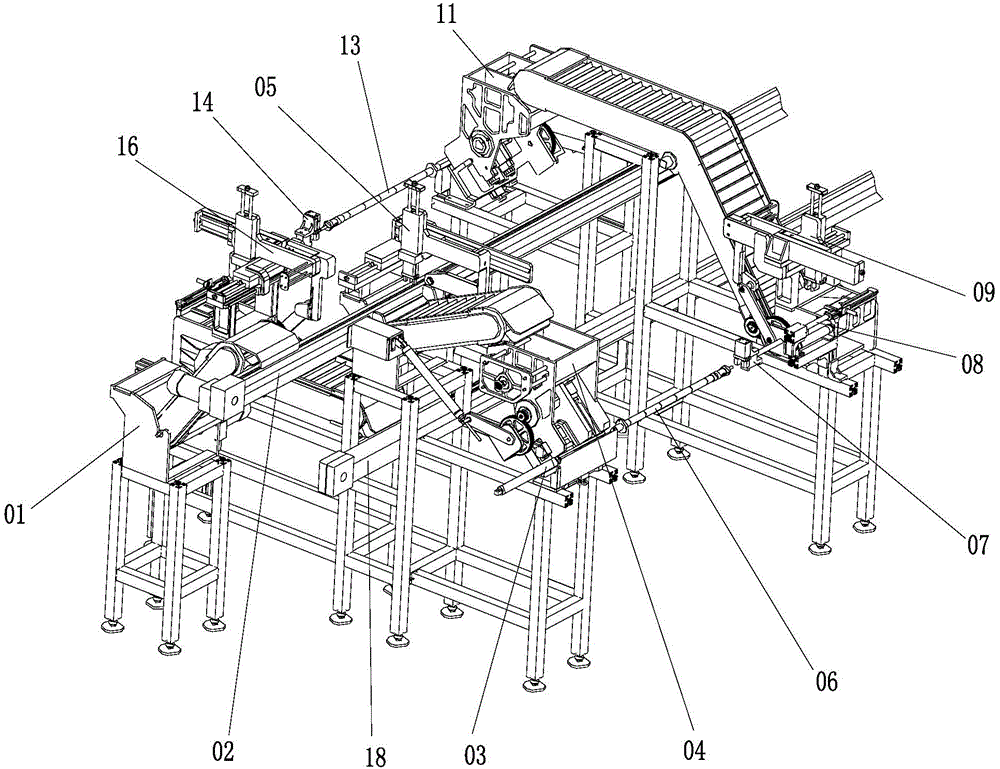

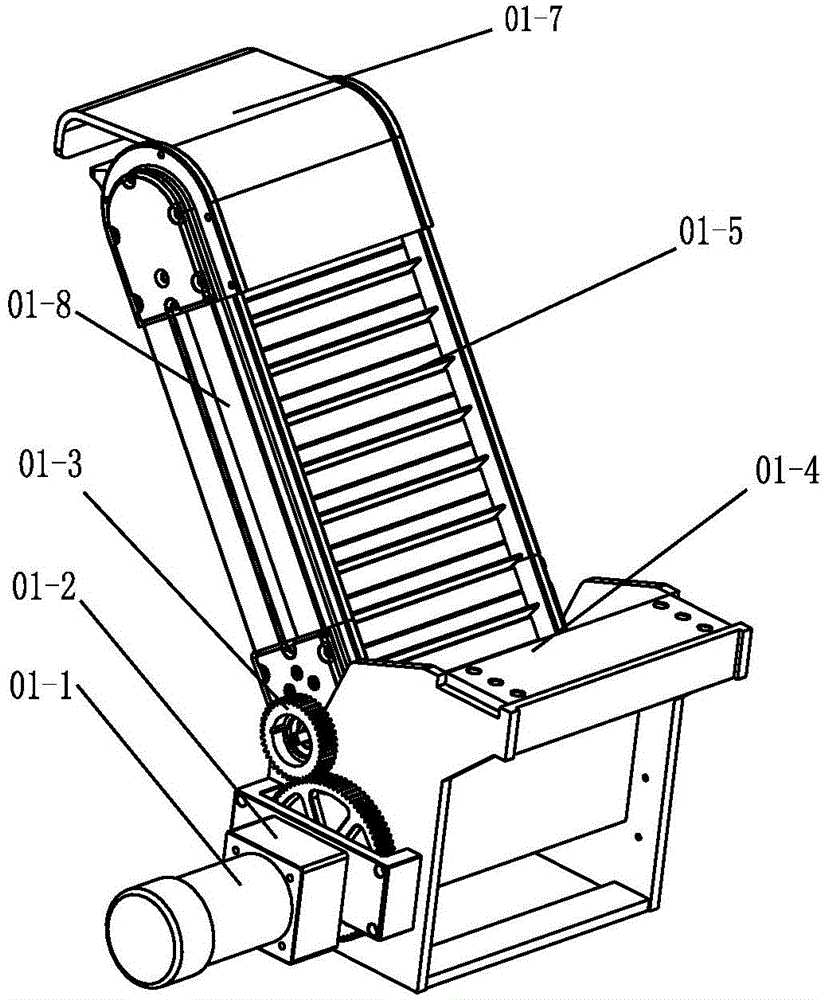

[0039] Below in conjunction with accompanying drawing, the present invention will be further described:

[0040] like figure 1 , figure 2 As shown, a modular turning automatic assembly line according to the present invention includes a height-adjustable support frame, and the bar material lifting mechanism assembly 01, bar material longitudinal conveying mechanism 02, Bar retrieving horizontal conveying manipulator assembly 05, adjustable buffer hopper assembly 04, lathe spindle rear feeding positioning device 06, lathe tool holder carriage manipulator 07, lathe discharging and receiving pneumatic device assembly 08, three-axis Automatic retrieving and lateral feeding manipulator assembly 09, second cycle rear feed buffer hopper assembly 11, second cycle lathe spindle rear feed positioning device 13, second cycle lathe tool holder carriage manipulator device 14, second cycle lathe Material discharging and receiving pneumatic device assembly 15, second cycle three-axis autom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com