Biogas fermentation tank top scum shell breaking device and shell breaking method

A biogas fermentation and shell breaking device technology is applied in the fields of bioreactor/fermenter combination, fermentation, bioreactor/fermenter for specific purposes, etc. It can solve problems such as scum encrustation and achieve the effect of improving utilization efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

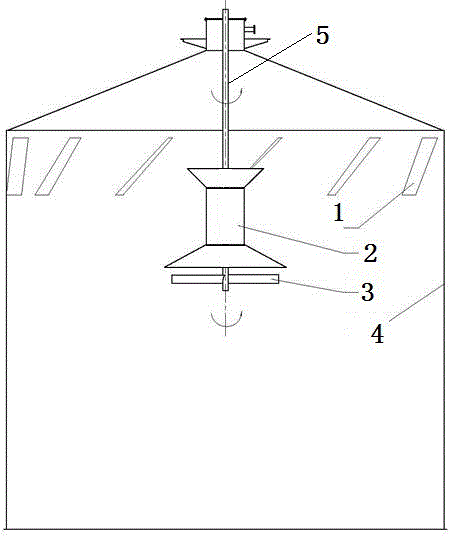

[0028] A shell-breaking device for scum at the top of a biogas fermentation tank, comprising a guide tube 2 and an agitator, the guide tube 2 is arranged in a biogas fermentation tank 4, and the upper end and the lower end of the guide tube 2 are set in the shape of a bell mouth, The middle part is cylindrical, and the top surface of the bell mouth at the upper end of the guide tube 2 is lower than the liquid level in the biogas fermentation tank 4; the agitator includes a motor, a reducer, a stirring shaft 5 and a stirring blade 3, and the motor is arranged outside the biogas fermentation tank 4 The top of the top, the stirring paddle 3 is located below the bell mouth of the lower end of the guide tube 2, one end of the stirring shaft 5 is connected to the motor through the reducer, and the other end passes through the inner cavity of the guide tube 2 and is connected to the stirring paddle 3.

[0029] A preferred implementation of this embodiment is that the cracking device f...

Embodiment 2

[0039] This embodiment further illustrates the present invention in conjunction with the accompanying drawings.

[0040] Such as figure 1 As shown, a scum cracking device at the top of a biogas fermentation tank includes a draft tube 2 , an agitator and a baffle 1 . The upper and lower bell mouths of the guide tube 2 are cylindrical in the middle, the stirring paddle 3 is located under the lower bell mouth of the guide tube 2, and the baffles 1 are set in the same direction, and are 45 o Welded on the walls of the biogas fermentation tank 4.

[0041] The upper part of the guide tube 2 is provided with a bell mouth, and the top surface is lower than the liquid level in the methane fermentation tank 4 . The lower part of the guide tube 2 is provided with a bell mouth, and the diameter of the bell mouth is larger than the diameter of the stirring paddle 3 .

[0042] The stirring paddle 3 is arranged under the bell mouth of the lower part of the guide tube 2, and the suction ge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com