Up-flow anaerobic sludge bed reactor and operation method

An up-flow anaerobic and sludge bed technology, used in anaerobic digestion treatment, waste fuel, etc., can solve the problem of low treatment efficiency of buried anaerobic digesters, increased reaction contact time, and inability to accumulate enough sewage. Sludge and other problems, to avoid the temperature gradient distribution phenomenon, increase the concentration, avoid the effect of biogas leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

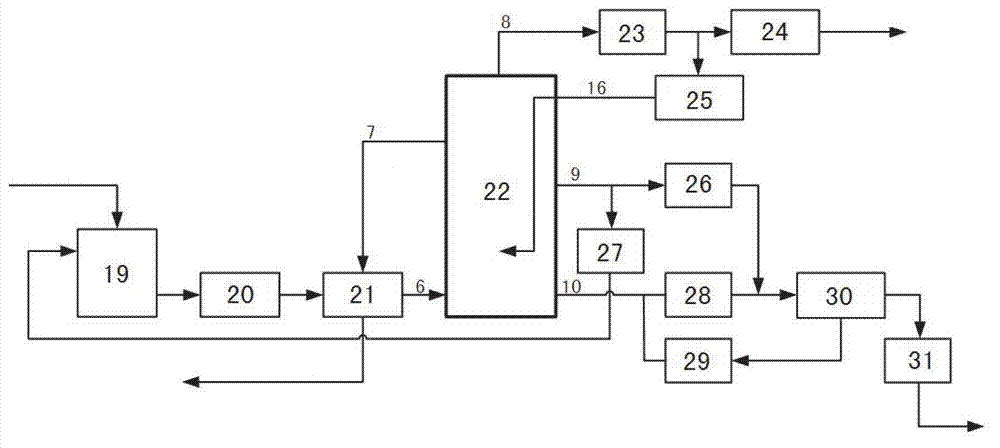

[0034]The fecal sewage produced by large pig farms is a high-solid organic sewage, which is a valuable resource. After anaerobic digestion, it can effectively remove a large amount of organic matter at a low operating cost, and can kill infectious bacteria. Realize the harmless treatment of feces and sewage, and at the same time recycle biogas and organic fertilizers.

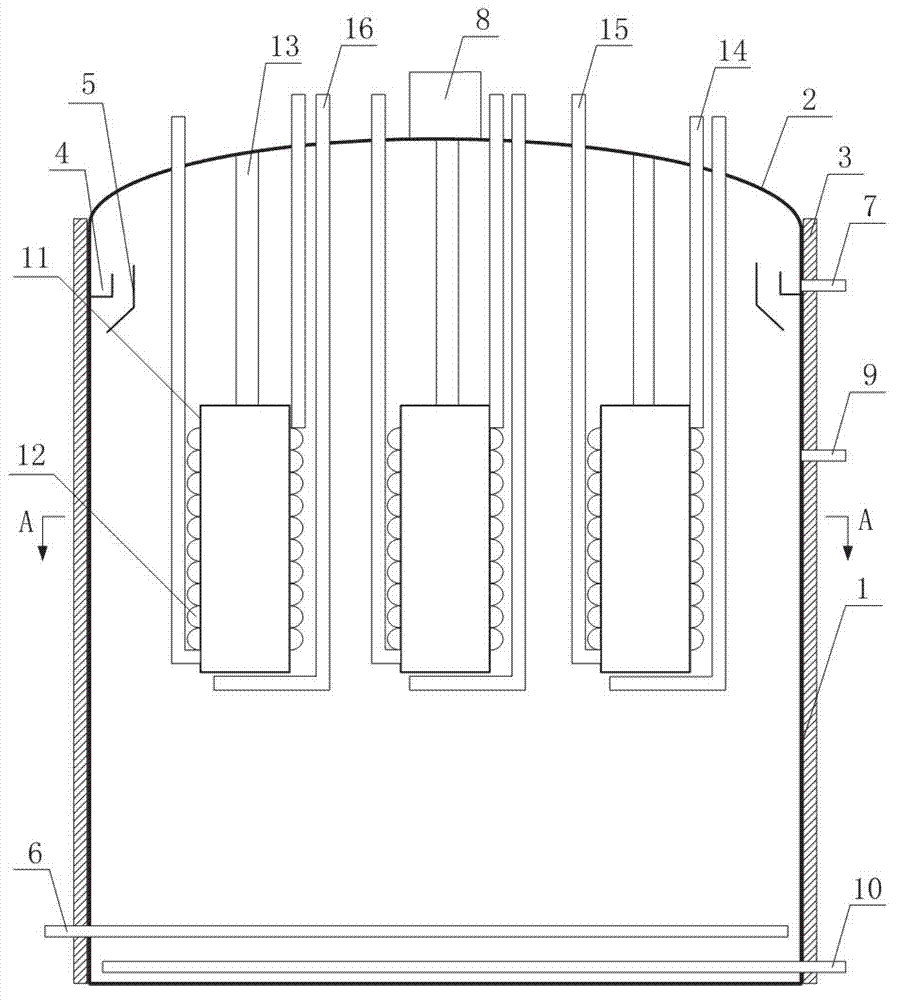

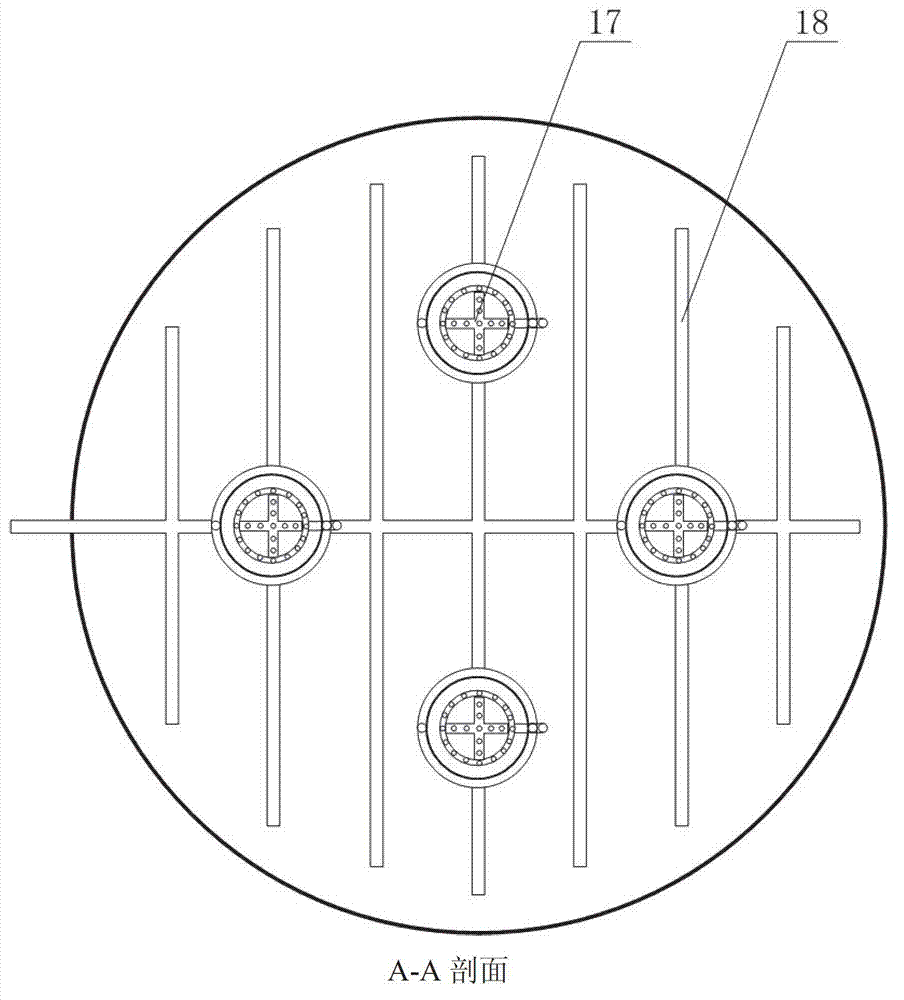

[0035] The structure of the upflow anaerobic sludge bed reactor is shown in figure 1 and figure 2 , mainly composed of tank body 1, tank top 2, insulation layer 3, outlet overflow channel 4, slag retaining plate 5, water inlet pipe 6, water distribution branch pipe 18, water outlet pipe 7, exhaust pipe 8, drain pipe 9, mud discharge Tube 10, diversion heating device and other components. The diversion heating device is composed of a diversion tube 11, a heating snake pipe 12, a bracket 13, a heating water inlet pipe 14, a heating return pipe 15, an aeration pipe 16, and an aeration head 17. It is suspended a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com