New energy biogas digester desulfurization purification and pressure stabilization system

A pressure-stabilized, biogas digester technology, applied in biochemical instruments, biochemical cleaning devices, biochemical equipment and methods, etc., to achieve the effects of reducing air pressure, increasing exhaust gas, and increasing gas production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

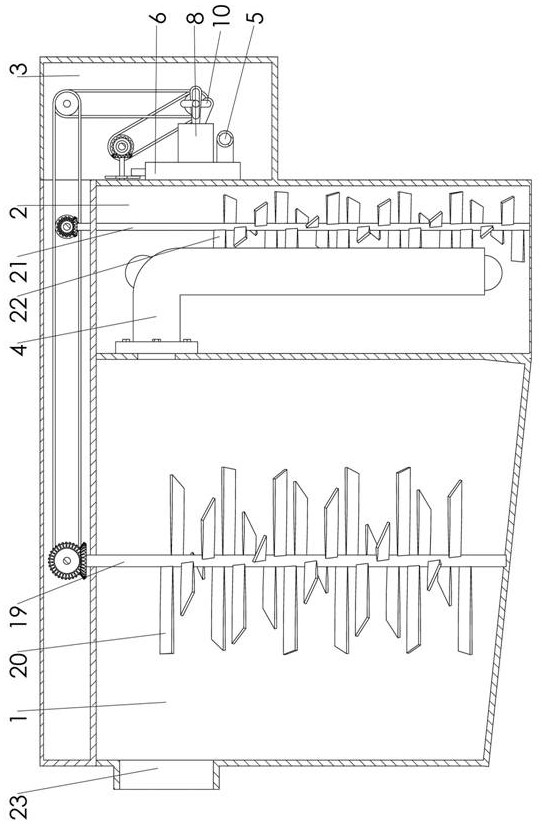

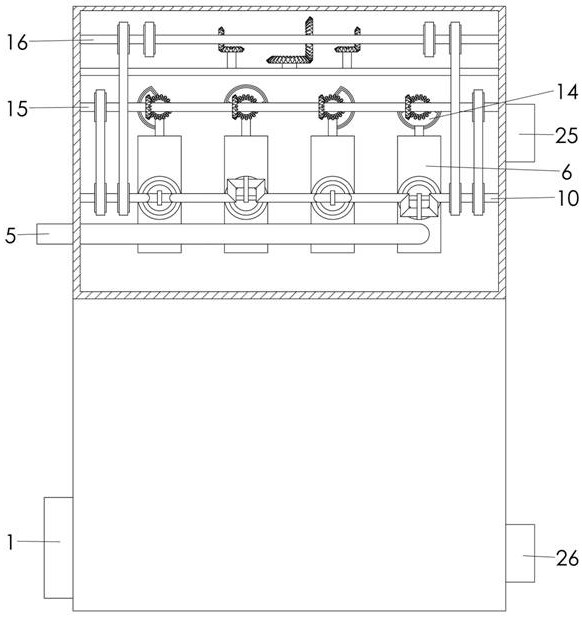

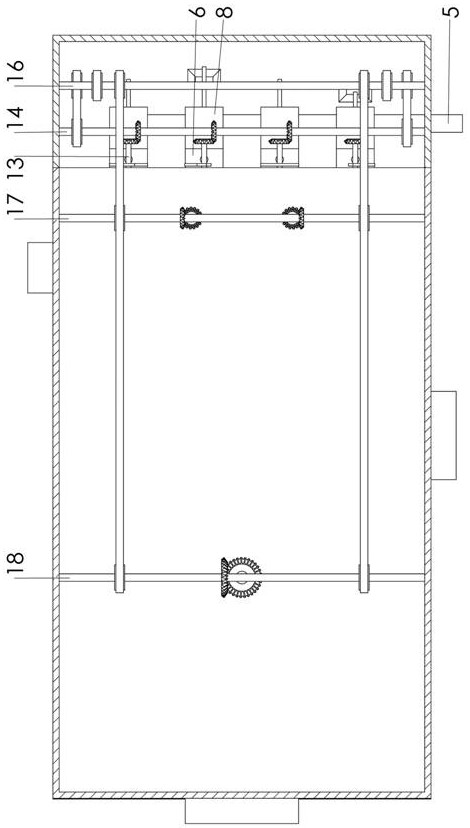

[0012] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0013] Depend on Figure 1 to Figure 6 Given, the present invention includes a biogas digester, a biogas digester is composed of a fermentation chamber 1, a desulfurization chamber 2 and a power chamber 3 arranged in sequence along the horizontal direction, the fermentation chamber 1 and the desulfurization chamber 2 are both airtight cavities, and the desulfurization chamber 2 is equipped with desulfurization There is a gas pipe 4 connected between the fermentation chamber 1 and the desulfurization chamber 2, and the gas pipe 4 passes the gas generated in the fermentation chamber 1 into the bottom of the desulfurization chamber 2; There are four two-position three-way valves 6 on the wall, and the four two-position three-way valves 6 are evenly distributed along the front and rear directions. The reversing outlet B, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com