Oil groove milling cutter of hard alloy cold-working mould pressing blank

A cemented carbide and molding technology, which is used in the field of machining tools, can solve the problems of inability to guarantee the quality of the machined surface, and achieve the effects of low cost, easy tool production and reduced cutting resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

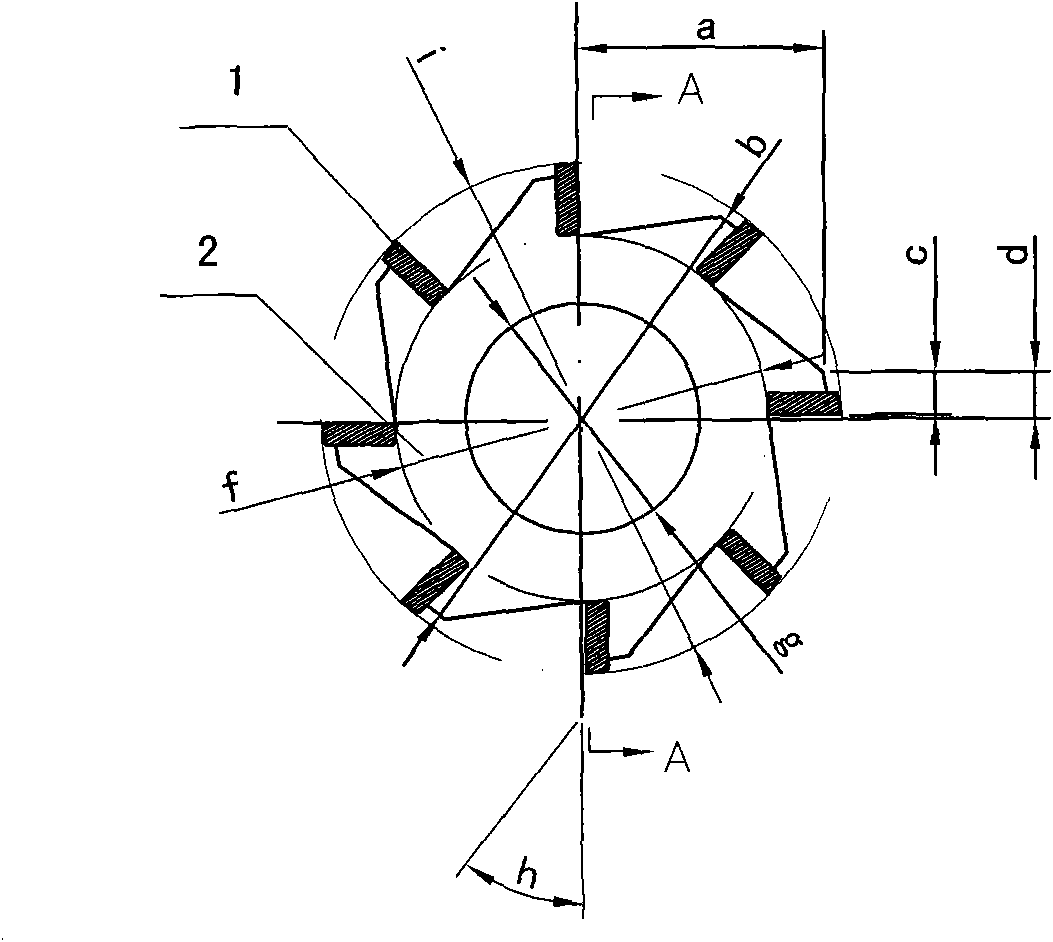

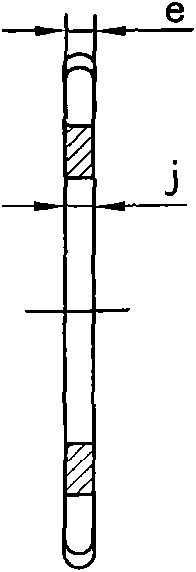

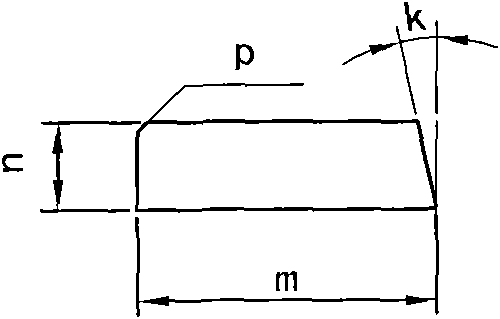

[0043] Figure 1 to Figure 5 The cemented carbide cold-work molded billet oil groove milling cutter shown in the present invention includes a steel matrix 2 with 8 serrations and 8 PCD blades 1, the back of the steel matrix serrations is designed as an inclined flat bottom, and the PCD blades 1 are welded on the steel matrix serrations; The dimensional parameters of steel substrate 2 and PCD blade 1 are as follows: main parameters b: Φ40mm, f: Φ30.2mm, h: 37°, i: Φ42.2mm, j: 5.6mm, k: 12°, r : 89°, y: 2°; other parameters a: 18mm~30mm, c: 2mm~10mm, d: 2mm~10mm, e: 6mm, g: Φ8mm~30mm, m: 3mm~20mm, n: 0.5mm~ 10mm, p: (0.2~4)X(15°~60°), s: 3mm.

[0044] Install the milling cutter on the universal tool grinder, set the cutter speed to 3600r / min; clamp the hard alloy cold pier mold blank on the indexing chuck, and use the indexing head to index the position of the oil groove, and process YG15 and YG20 respectively Cold pier molded blank oil grooves in two carbide grades.

[0045]...

Embodiment 2

[0048] Change the geometric angle of the PCD blade 1 to h: 35°, k: 10°, r: 85°, y: 3°, and the other conditions are the same as in the first embodiment.

[0049] Install the milling cutter on the universal tool grinder, set the cutter speed to 3600r / min; clamp the cold pier molded blank on the indexing chuck, and use the indexing head to index the position of the oil groove. Process YG15 and YG20 cold pier molded blank oil grooves.

[0050]During processing, the workpiece is pushed steadily at a slow speed by manual operation. The processing size (width×depth) is 3.2mm×2.5mm four oil grooves, and each oil groove is processed once.

[0051] During the processing, it was found that the milling cutter vibrated slightly. After the processing was completed, the edge of the oil groove had a very slight chipping. The surface roughness was rougher than that of Example 1, but it still met the processing requirements of the oil groove of the cold pier molded blank.

Embodiment 3

[0053] Change the radial dimension of the steel matrix 2 to b: Φ44.0mm, f: Φ34.0mm, i: Φ46.0mm, and other conditions are the same as in the first embodiment.

[0054] Install the milling cutter on the universal tool grinder, set the cutter speed to 3600r / min; clamp the cold pier mold blank on the indexing chuck, and use the indexing head to index the position of the oil groove, and process two grades of YG15 and YG20 respectively Cold pier molded blank oil tank.

[0055] During processing, the workpiece is pushed steadily by manual operation, and pushed at a slow speed at a constant speed. The processing size (width × depth) is 3.2mm×2.5mm four oil grooves, and each oil groove is processed at one time.

[0056] Inspection after processing shows that the processed surface has slight knife jumping phenomenon, slightly rough (surface roughness is Ra1.6), and the edge of the oil groove is slightly chipped, which still meets the processing requirements of the cold pier molded blank...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com