Device for producing large-area surface discharge by utilizing water electrodes

A technology of creeping discharge and discharge device, applied in the field of plasma, can solve the problems of complex preparation process, limited discharge time, and high preparation cost, and achieve the effects of low technological requirements, improved heat dissipation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiment of the present invention will be further described below in conjunction with the structural schematic diagram

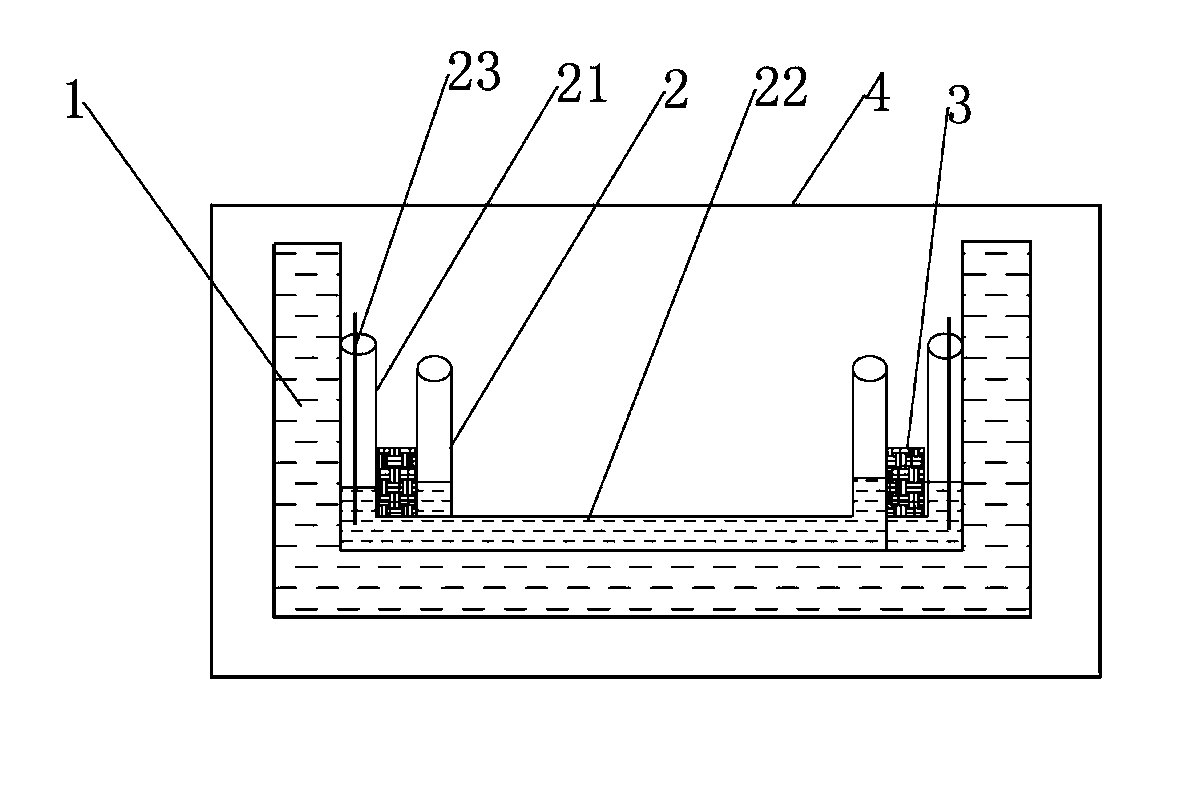

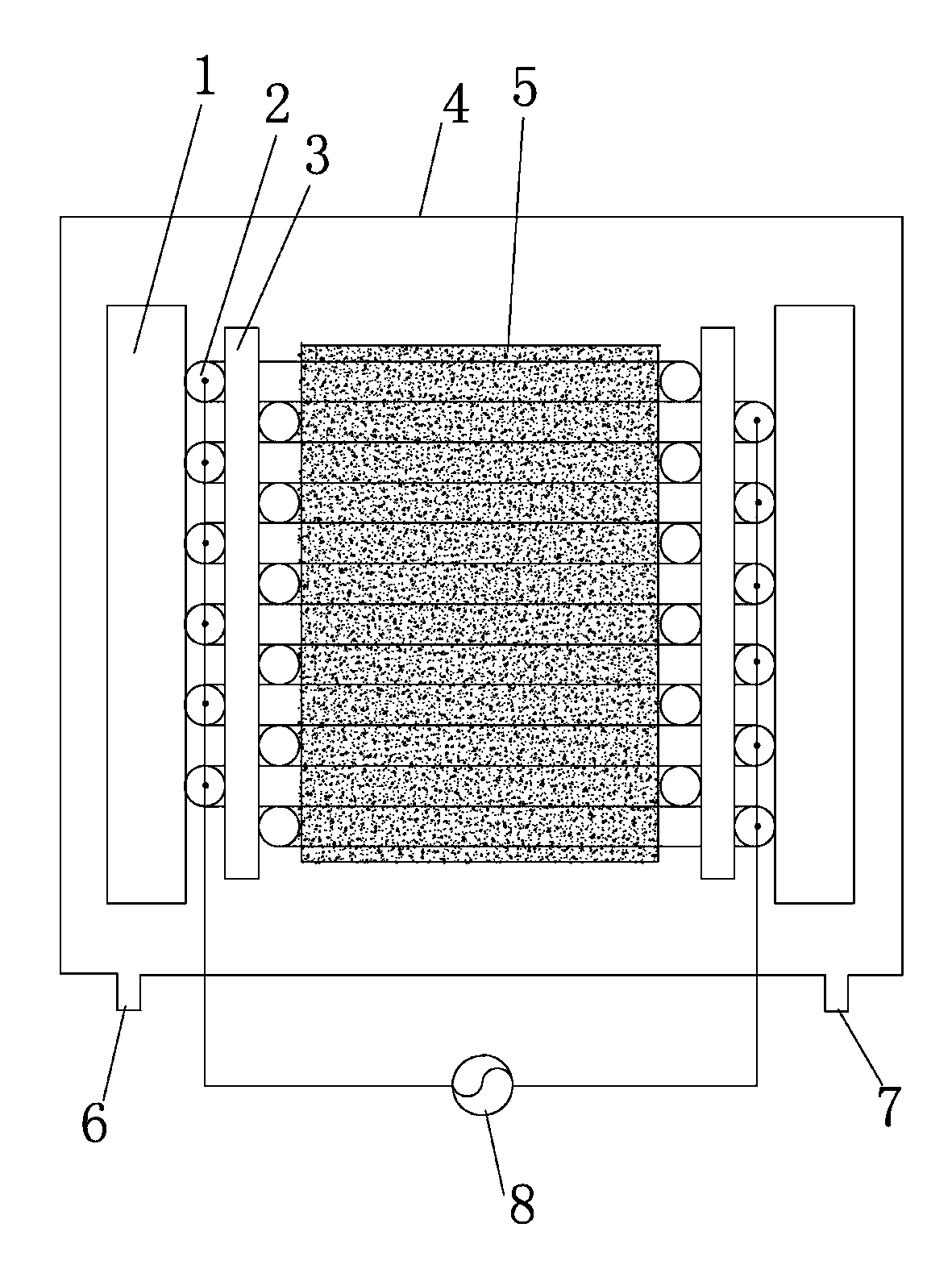

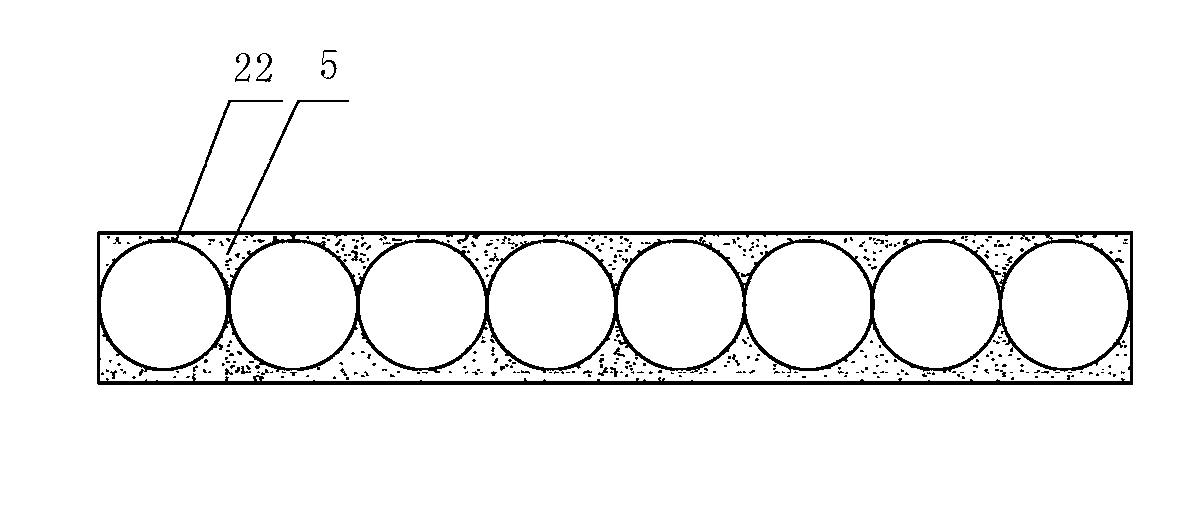

[0027] figure 1 , figure 2 , image 3 As shown, the device that utilizes the water electrode to generate large-area creeping discharge includes a sealed tank 4 and a discharge device installed in the sealed tank, and the discharge device includes several U-shaped tubes 2 arranged in sequence; the U-shaped tube The standpipes 21 on each side of the standpipes are aligned at intervals and adjacently staggered into two rows, and an insulating medium plate 3 is installed between the two rows of standpipes adjacent to each side; the horizontal bottom pipes 22 of each U-shaped pipe are embedded in insulating glue side by side In layer 5; a water electrode 23 is placed in a vertical tube of each U-shaped tube, and the water electrodes placed in the aligned vertical tubes are jointly connected to an output end of the high-voltage AC power ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com