Motor train roof composite insulator with interface breakdown prevention function

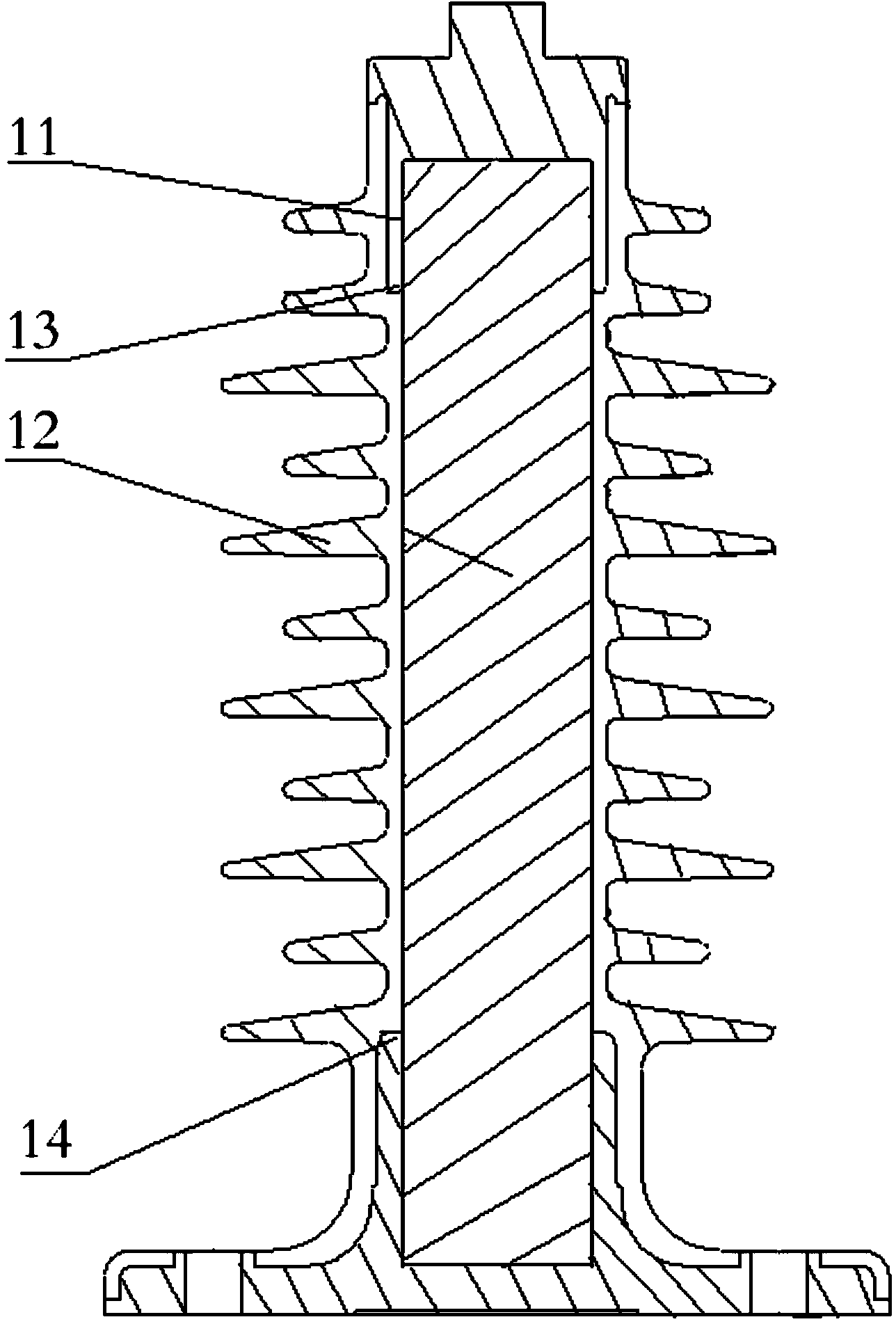

A composite insulator, motor vehicle roof technology, used in insulators, insulators, motor vehicles, etc., can solve problems such as unfavorable withstand impulse voltage, interface breakdown, etc. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

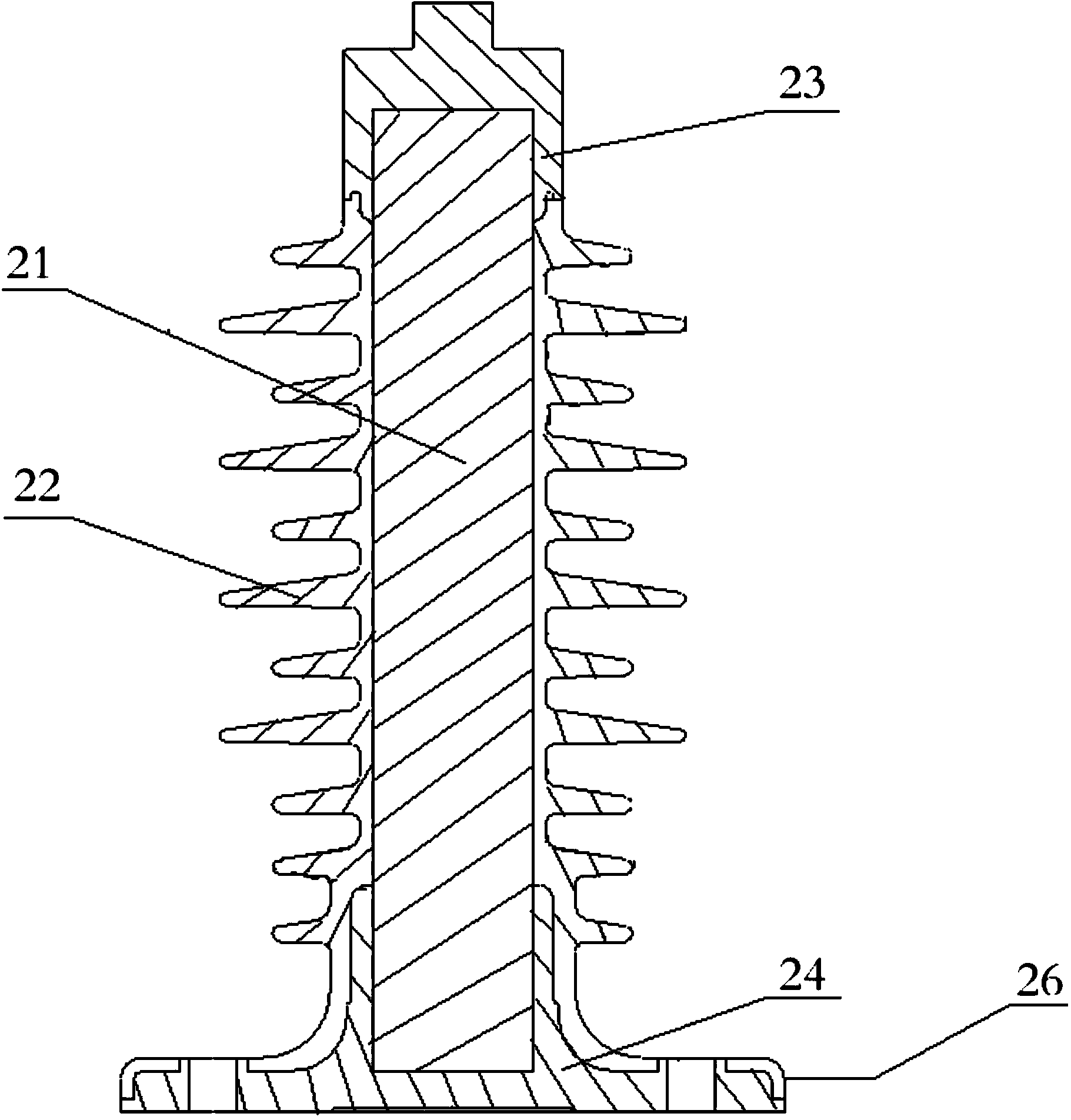

[0029] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0030] Aiming at the deficiencies of the prior art, this embodiment provides a new composite insulator, the structure of which is as follows figure 2 As shown, the motor car roof composite insulator with anti-interface breakdown includes a support body 21, and at least 5 groups of the sheds 22 arranged side by side in the axial direction are arranged around the side wall of the support body 21, wherein the at least 5 groups The set of sheds includes: each of at least four sheds 22 at the upper end includes a large umbrella and a small umbrella, and at least one set of sheds 22 at the lowermost end includes two small umbrellas.

[0031] In this embodiment, as a preferred solution, the diameter of the large umbrella is 172mm-180mm.

[0032] In this embodiment, as a preferred solution, the diameter o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com