Automatic production technology of chlorinated paraffin

A technology of chlorinated paraffin and production process, which is applied in the production mode of chlorinated paraffin, automatic production and automatic control process of chlorinated paraffin, and can solve the problem of high energy consumption of forced circulation in the chlorination process, the inability to realize automatic unmanned operation, explosion of electrical wires to avoid explosion and fire accidents, shorten response time, and solve safety problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to further elaborate the technical means and effects that the present invention adopts for reaching the intended purpose of the invention, below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure, characteristics and details of the chlorinated paraffin automated production process proposed according to the present invention Its effect is described in detail below.

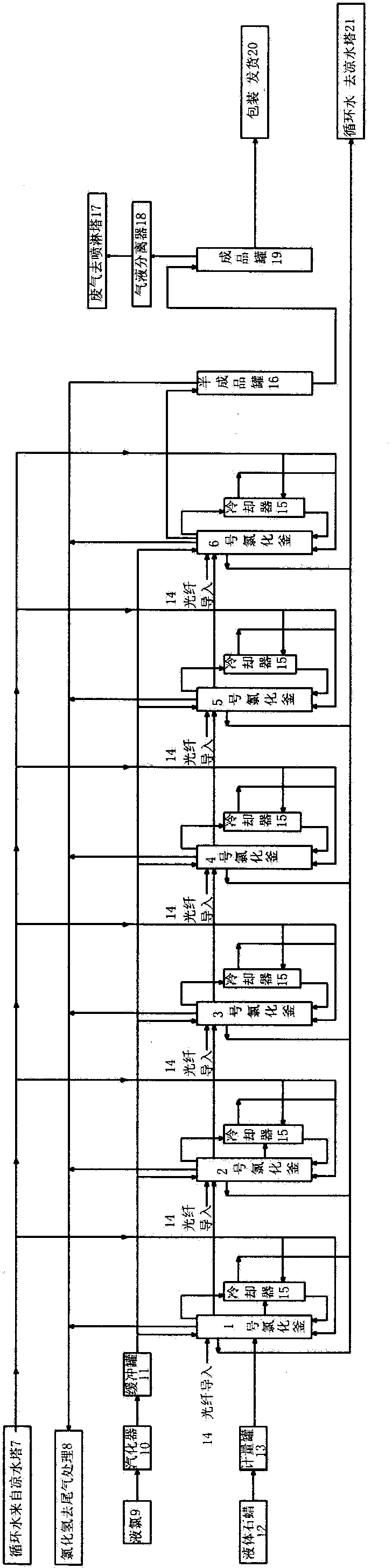

[0035] figure 1 It is a production process flow chart of the present invention. Such as figure 1 As shown, the process scheme adopted by the present invention can realize the continuous reaction and continuous discharge of the chlorination tank, shorten the chlorination reaction time (can be shortened to about 22 hours-24 hours from the 25-28 hours of the traditional process), and the chlorine gas conversion rate is high (The conversion rate of chlorine can reach more than 98%), and the main raw material and electricity consumption are r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com