Processing method and processing device for graded desorption of residue hydrotreating excretion catalyst in ebullated bed

A technology for expelling catalyst and bed residue oil, applied in chemical instruments and methods, catalyst regeneration/reactivation, physical/chemical process catalyst, etc., can solve the problems of clean recovery of catalyst particles that have not yet been developed, poor effect, and large investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

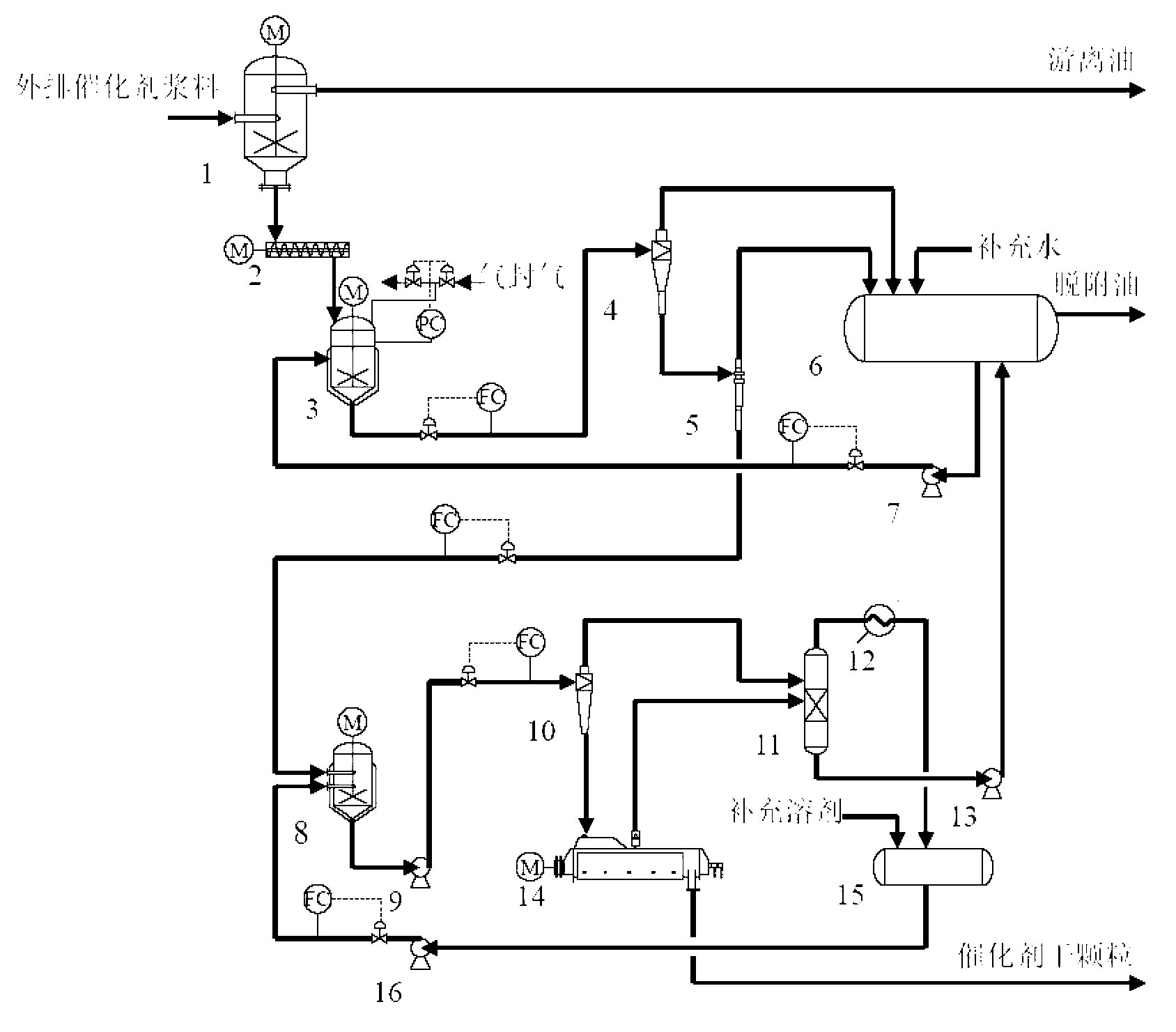

Image

Examples

Embodiment 1

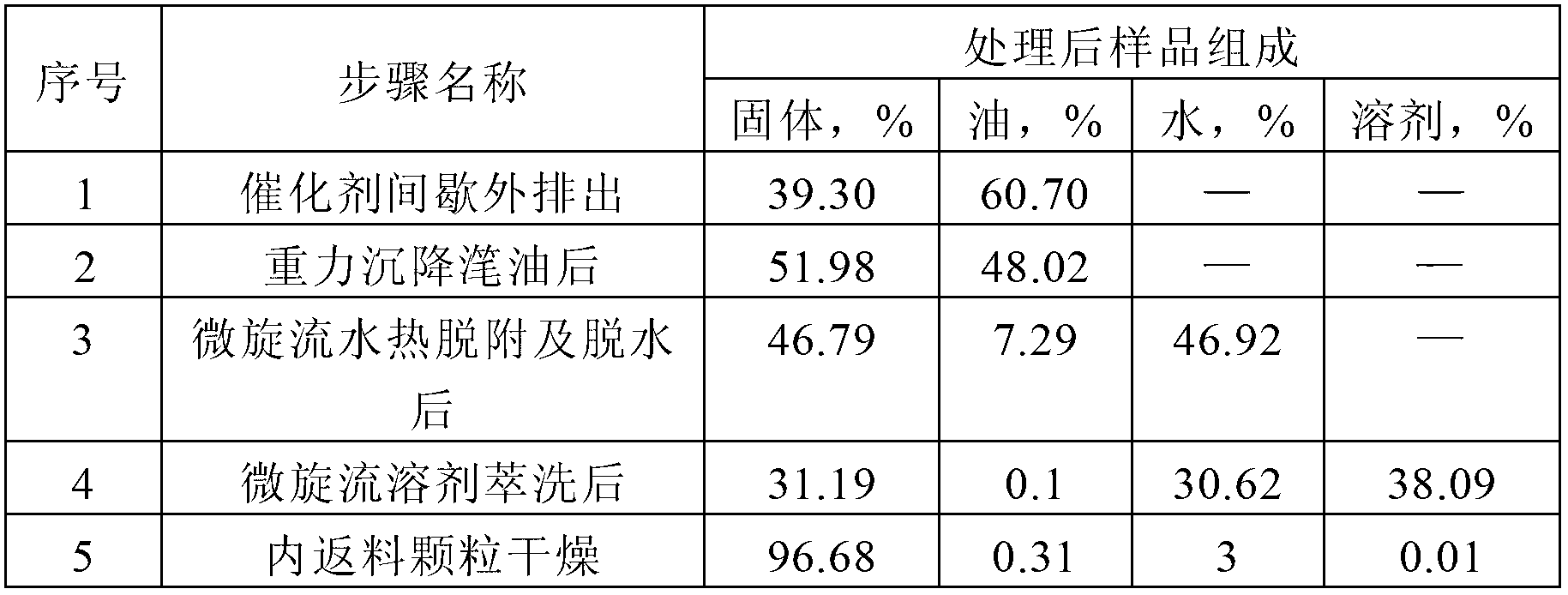

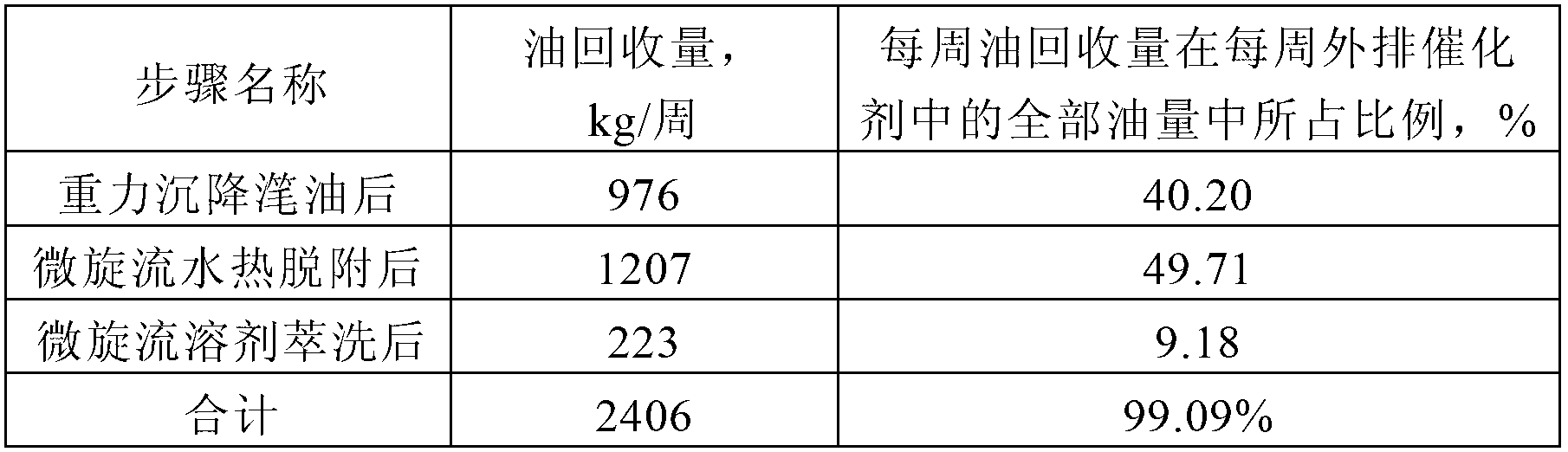

[0108] In a 50,000-ton / year ebullated-bed residual oil hydrogenation unit, the exhausted catalyst is treated according to the method of the present invention, and its specific operation process and effects are described as follows:

[0109] 1. Properties of efflux catalyst

[0110] During the online discharge process of the efflux catalyst, the total amount of efflux per week is 4 tons, including 2.4 tons of oil.

[0111] The fresh catalyst carrier is microspherical particles with a particle size of 0.4-0.5mm and a BJH specific surface area of 416.308m 2 / g, the pore volume is 0.71ml / g, and 50% of the pore size distribution is below 7nm.

[0112] The petroleum pollutants adsorbed on the surface of the outer catalyst particles and in the inner pores are mainly diesel distillation range, and may contain a small amount of wax oil components.

[0113] 2. Implementation process

[0114] With reference to the specific implementation steps of the present invention, as follows: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com