Automatic environmentally friendly livestock and poultry manure high temperature aerobic fermentation facility

A technology of livestock and poultry manure and aerobic fermentation, applied in organic fertilizers, climate change adaptation, fertilization devices, etc., can solve the problems of adverse effects on agricultural production, inability to kill harmful bacteria, low composting temperature, etc. Small, simple structure, good fermentation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to more clearly illustrate the technical scheme of the present invention, and cannot limit the protection scope of the present invention with this.

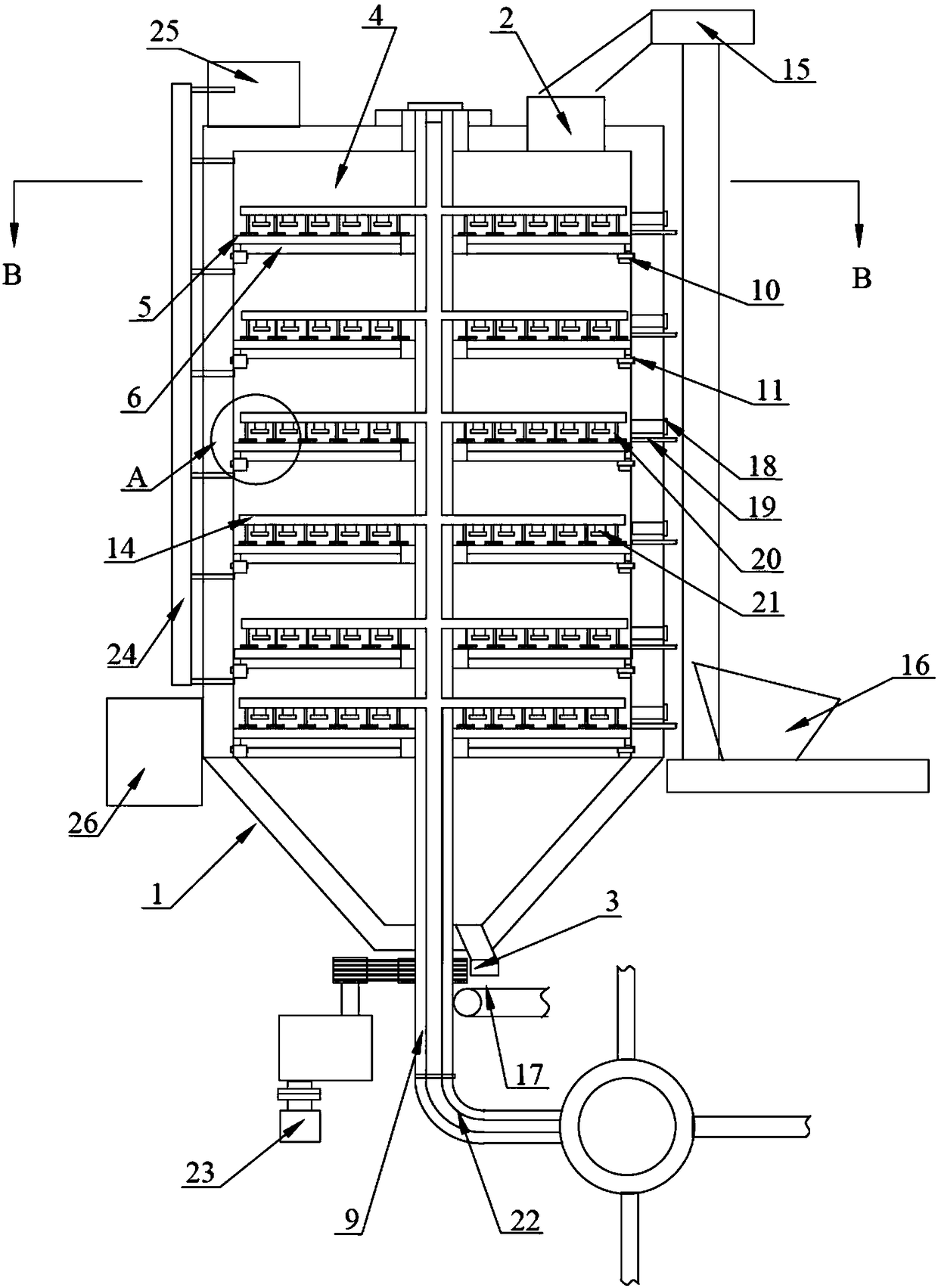

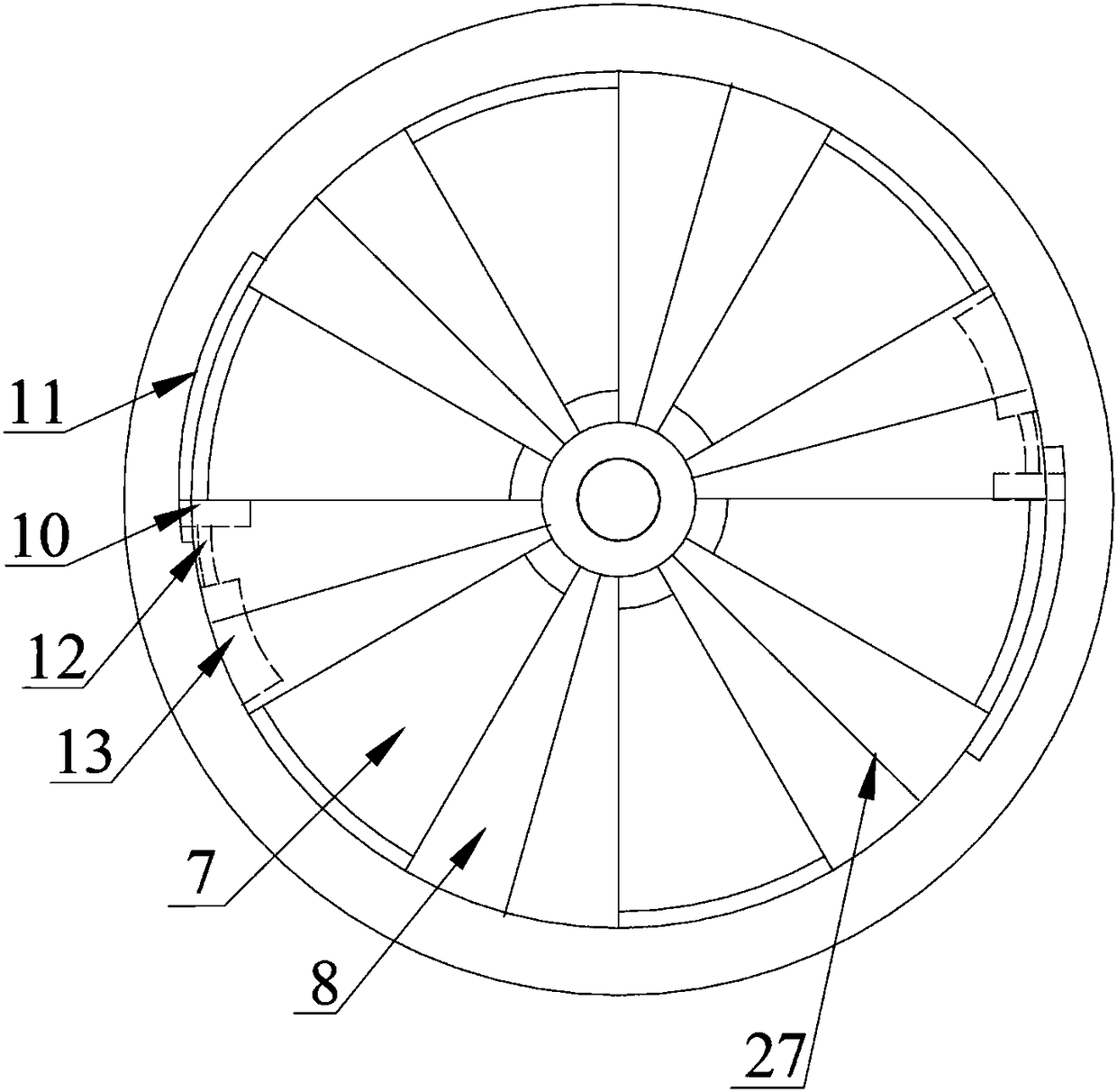

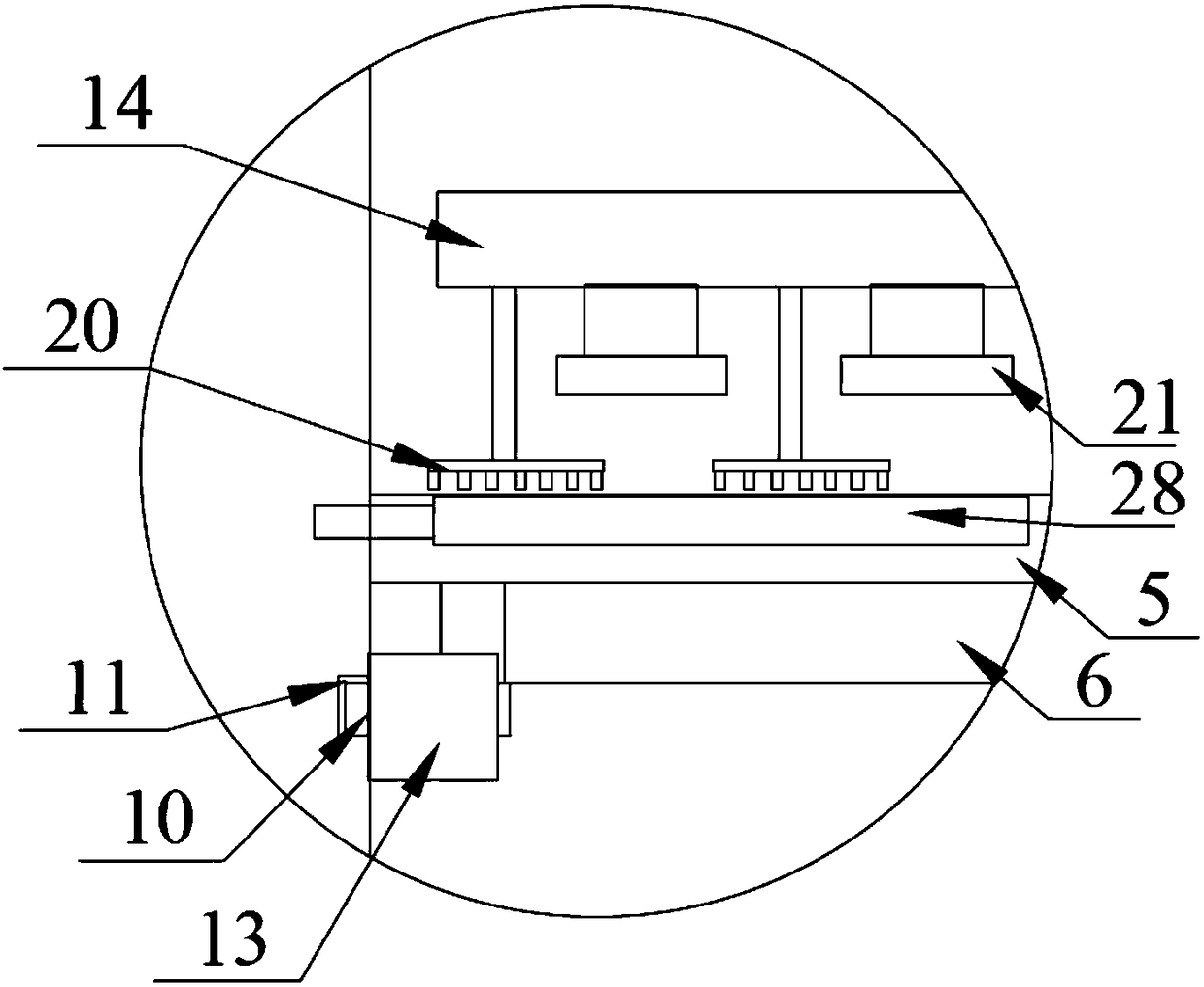

[0037] Such as Figure 1~3 As shown, the present invention is a fully automatic environment-friendly high-temperature aerobic fermentation equipment for livestock and poultry excrement. The fermentation equipment includes a fermenter body 1 installed on a base, and the top of the fermenter body 1 is provided with a feed port 2 for fermenting The bottom of the tank body 1 is provided with a discharge port 3, and the interior of the fermentation tank body 1 is divided into seven relatively independent fermentation chambers 4 from top to bottom, and several Layer partitions, the partitions include a fixed partition 5 and a rotating partition 6, the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com