Cereal vacuum storage device

A storage device and grain vacuum technology, applied in the fields of food science, food preservation, application, etc., can solve the problems of inability to achieve long-term high-quality storage of grains, high manufacturing costs, and inability to guarantee other conditions of grains, and achieve the convenience of wrapping grains, avoiding the Withstand vacuum pressure, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

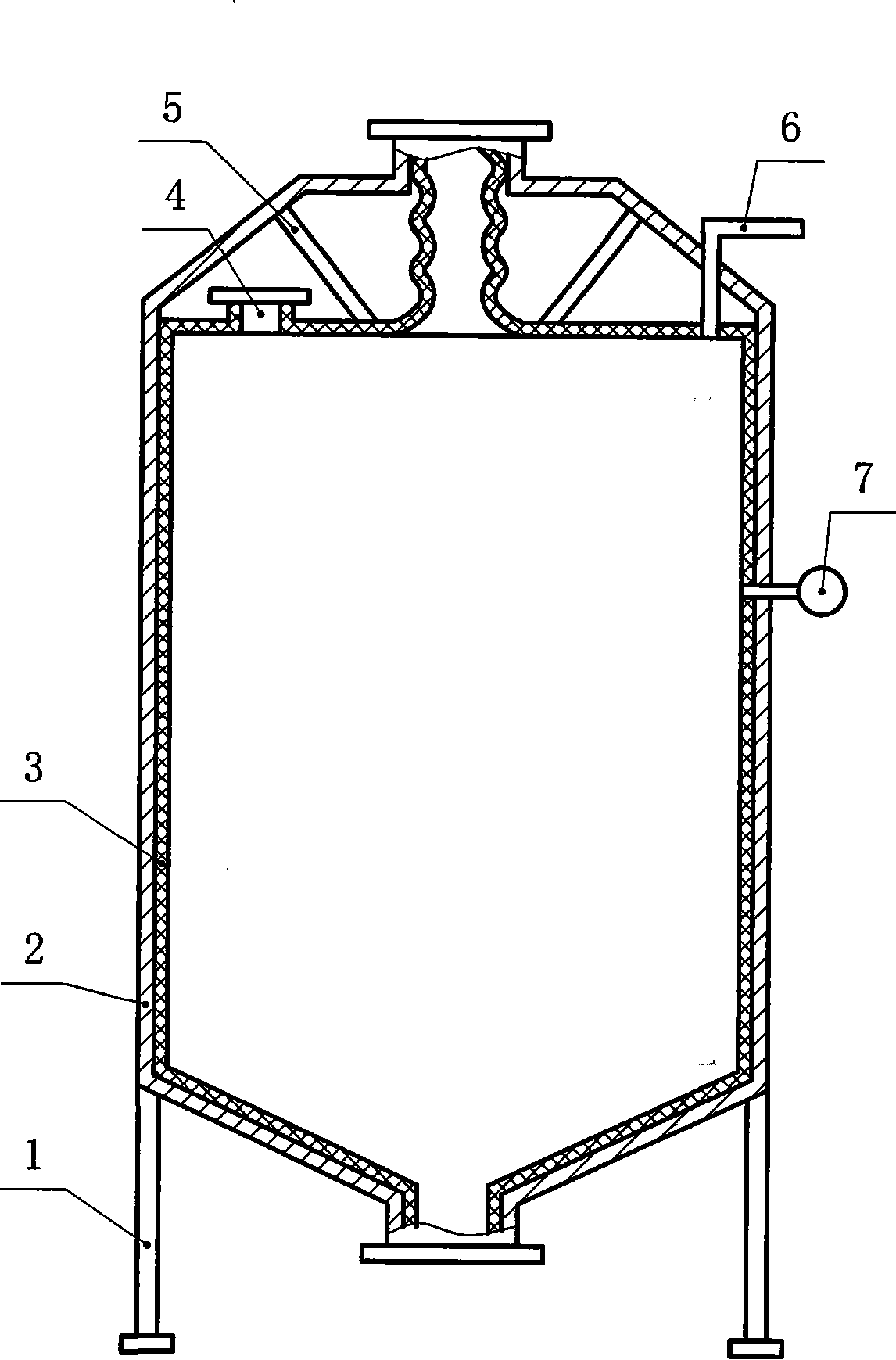

[0019] Embodiment one: see figure 1 , in the figure, the hollow grain storage bin body 2 of the grain vacuum storage device is a circular vertical bin body, and its upper and lower ends are respectively provided with an inlet bin and an outlet bin, and the inlet bin and the outlet bin are respectively A sealing cover (not shown in the figure) is provided, the lower end of the hollow grain storage bin body 2 is provided with a support 1, and a flexible bag body 3 is set in the inner cavity of the hollow grain storage bin body 2, and the size and shape of the flexible bag body 3 are the same as those of the hollow grain storage bin body. The inner cavity of the grain storage silo body 2 is matched, and the flexible bag body 3 is respectively provided with an inlet pocket and an outlet pocket. The silo mouth is corresponding, which is convenient for feeding in and out of the material, and a sealing mechanism (not shown in the figure) is respectively arranged on the feeding bag mo...

Embodiment 2

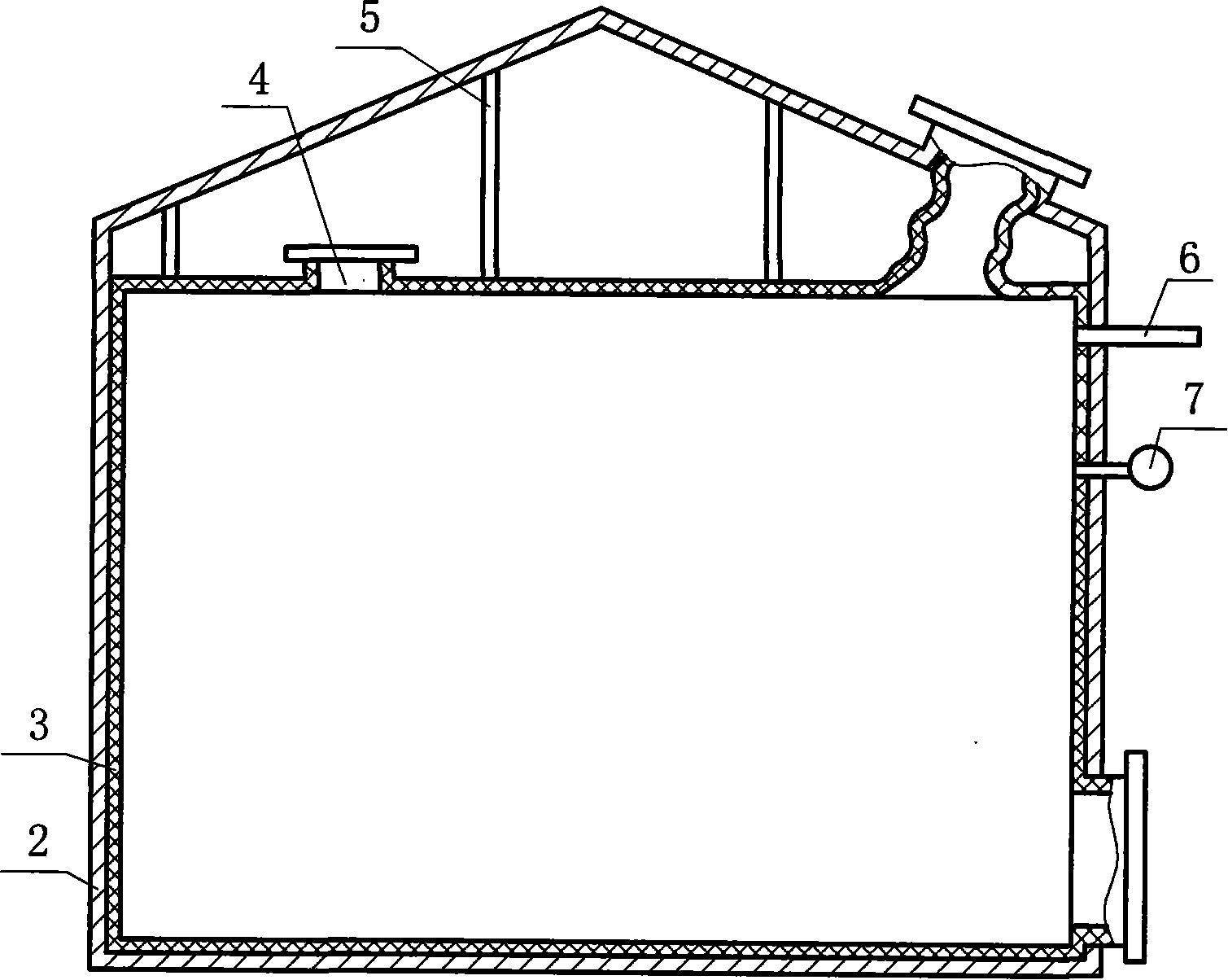

[0023] Embodiment 2: This embodiment is basically the same as Embodiment 1, and the similarities will not be repeated. The difference is that the hollow grain storage bin body 2 is a room-shaped horizontal bin body, and its feeding bin is arranged on the upper slope. Its discharge bin is arranged on the side of the lower part.

Embodiment 3

[0024] Embodiment 3: This embodiment is basically the same as Embodiment 2, and the similarities will not be repeated. The difference is that there are more than one flexible bag (can be two, three, four or more, determined according to needs) ), and the quantity of the feed bin and the discharge bin on the hollow grain storage silo is consistent with the quantity of the flexible bag body, so that the feed bag and the discharge bag provided on each flexible bag are all consistent with an inlet The feed bin port corresponds to the discharge bin port.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com