Ultra-high magnification lithium ion battery

A technology of lithium-ion battery and multiplier, which is applied in secondary batteries, circuits, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

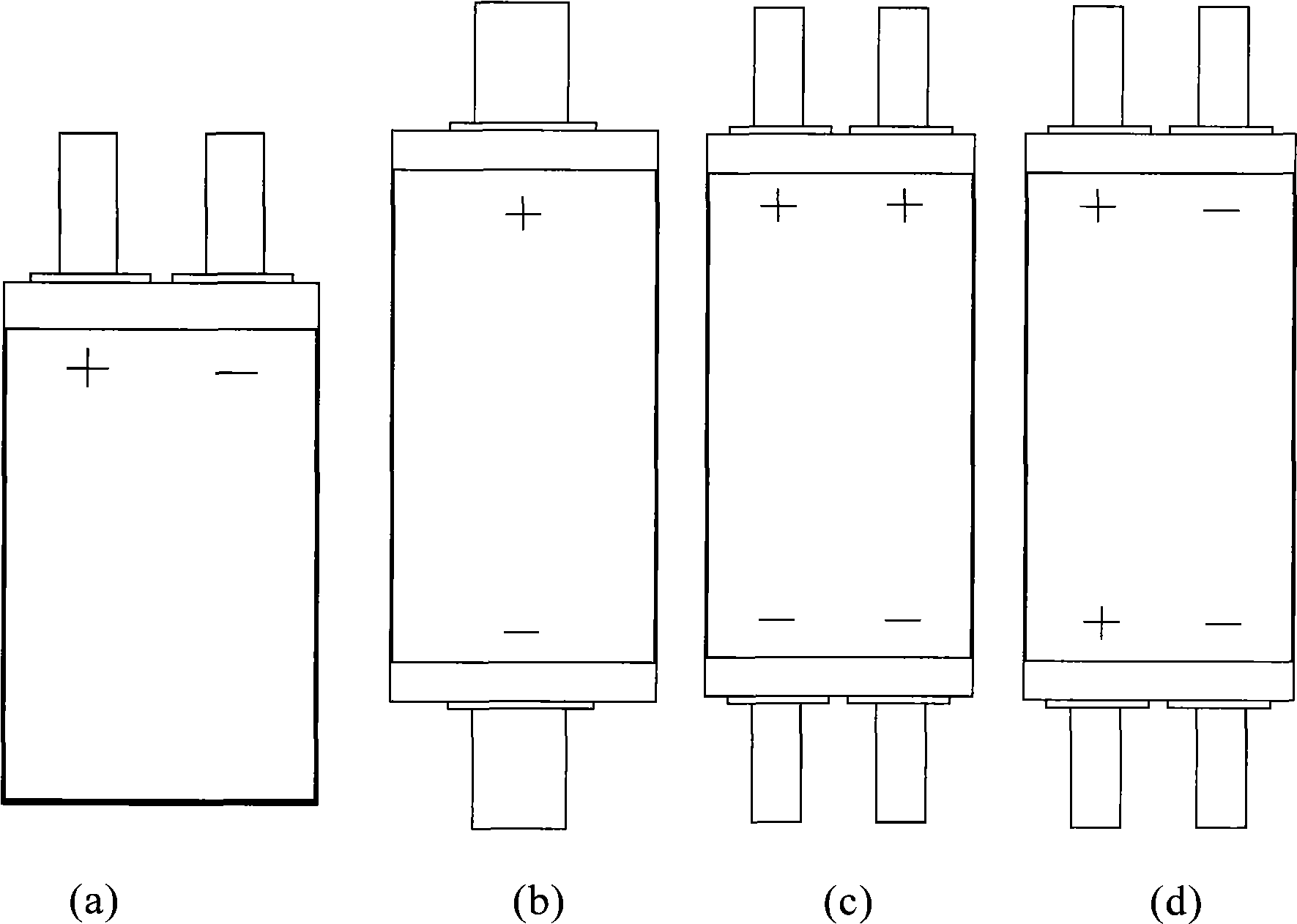

[0023] Taking the manufacturing process of 2500~5000mAh ultra-high rate lithium-ion battery as an example to illustrate, the battery structure is as follows: figure 1 (a) shown. Implement as follows:

[0024] The preparation of positive electrode slurry: N-dimethylpyrrolidone (NMP) was used as solvent, and the active material was modified porous spherical lithium cobaltate (LiCoO 2 ), the conductive agent is super conductive carbon black (Super P) and vapor grown carbon fiber (VGCF), and the addition ratio of NMP is between 40% and 65%. The ratio used in this example is: LiCoO 2 :Super P:VGCF:PVDF:NMP=90:3:2:5:60. First LiCoO 2 , Super P, and VGCF are pre-dispersed by ball milling in a ball mill, so that the conductive agent is evenly dispersed in LiCoO 2 Particle surface; then add PVDF to NMP, stir for 2-4 hours, add the treated positive electrode mixture into PVDF peptizer three times, stir at high speed for 6-8 hours, then vacuumize to remove air bubbles and wait for c...

Embodiment 2

[0032] In this example, the positive and negative electrode formula, electrolyte, separator, and tabs are the same as in Embodiment 1, but the preparation method of the positive and negative electrode slurry is not consistent with Embodiment 1. The preparation of positive electrode slurry adopts the formula in Embodiment 1. Add PVDF to NMP and stir for 2 to 4 hours; then add VGCF to PVDF glue and stir for 3 to 4 hours; then add Super P to the above mixture and stir for 2 ~3h; finally LiCoO 2 After adding and stirring evenly, vacuumize to remove air bubbles, and the post-process production is the same as that of Embodiment 1 to complete the positive electrode sheet production.

[0033] For the preparation of negative electrode slurry, add CMC to deionized water and stir for 3-4 hours; then add Super P to CMC glue and stir for 3-4 hours; then add MCMB to the above mixture and stir for 4-6 hours; finally, add SBR After adding and stirring evenly, evacuate to remove air bubbles, ...

Embodiment 3

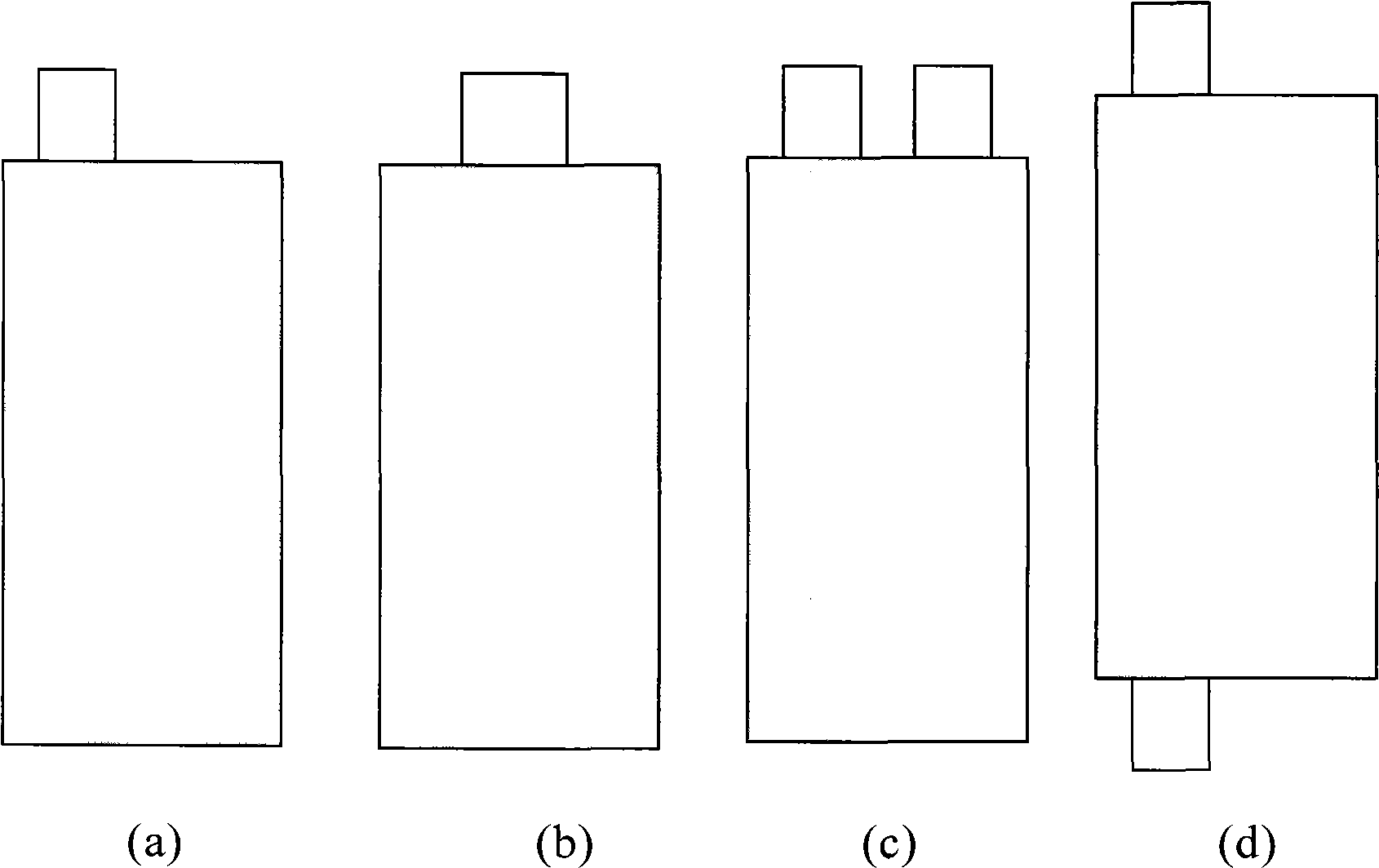

[0035] The preparation method of the positive and negative electrode formulations, electrolyte, diaphragm, and tabs of this embodiment is consistent with that of Embodiment 1, but the current collection method of the positive and negative electrodes is inconsistent with Embodiment 1. Embodiment 2 The pole piece adopts the middle collector of single-side single-pole lug respectively (such as figure 2 As shown in (b), same-side double-pole current collection (such as figure 2 (c) shown), different side bipolar tab current collection (such as figure 2 (d) shown). The positive and negative electrode sheets of the above-mentioned shape are stacked and assembled in the order of separator, negative electrode, separator, positive electrode, separator, and negative electrode to make a battery (specifically as follows: figure 1 (b), 1(c), and 1(d) shown), the post-process production is the same as that of Embodiment 1 to complete the production of the battery.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com