Microwave-assisted dynamic continuous calcining device and method for lithium-ion battery material

A lithium-ion battery and microwave-assisted technology, which is applied to lighting and heating equipment, furnace materials, furnace components, etc., can solve the problems of large environmental impact and low heat utilization rate, and achieve low environmental impact, high heat utilization rate, and avoid temperature gradient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

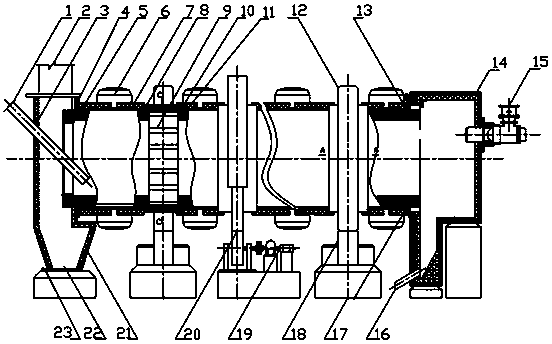

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

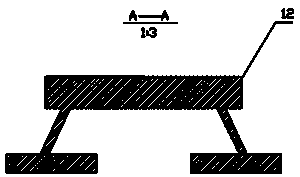

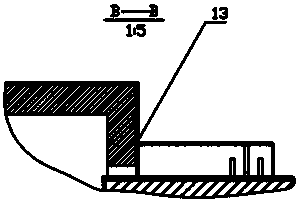

[0031] refer to Figure 1-4 , this embodiment includes a rotary kiln body, a transmission device and a power device. The power device is connected to the rotary kiln body through a transmission device. The rotary kiln body is supported on a reinforced concrete base 17 by supporting wheels 18 and rolling rings 12. The fixed inclination of the body is 6%. The rotary kiln body includes a rotary kiln shell 11, and an independent microwave emitter 6 is continuously arranged on the shell 7 of the rotary kiln body. The microwave emitter 6 is connected with a waveguide, and the waveguide is connected to the rotary kiln shell 11; the rotary kiln body is different The temperature in the warm zone is controlled by adjusting the microwave power of the microwave transmitter 6; a discharge device 16 is provided at the kiln head of the rotary kiln ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com