Method for recovering metal from used Li ion cell

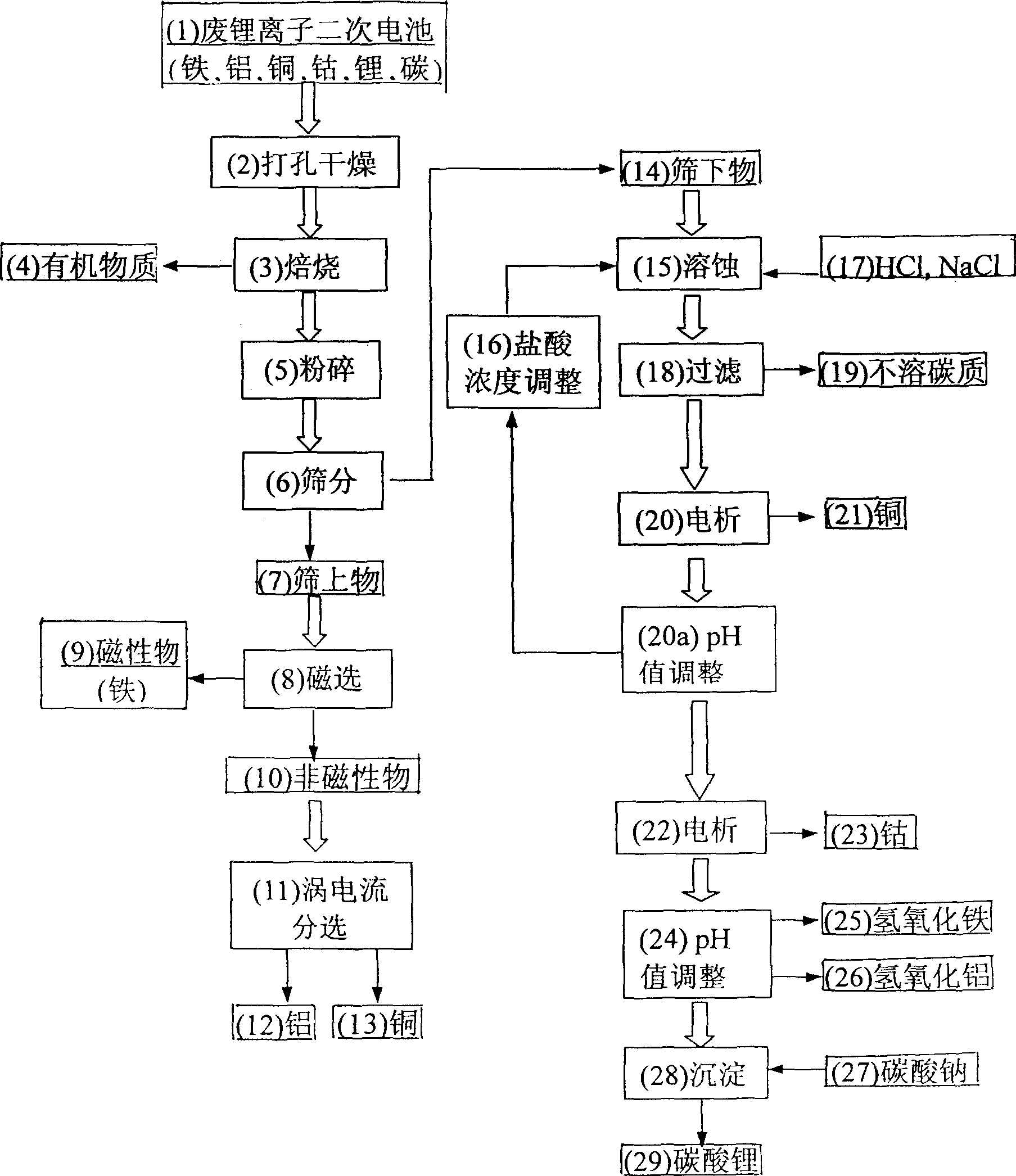

A lithium-ion battery and metal technology, which is applied to lithium carbonate and copper recovery, can solve the problems of low metal taste and low identification rate of physical properties, etc., and achieve the effect of reducing loss and improving corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

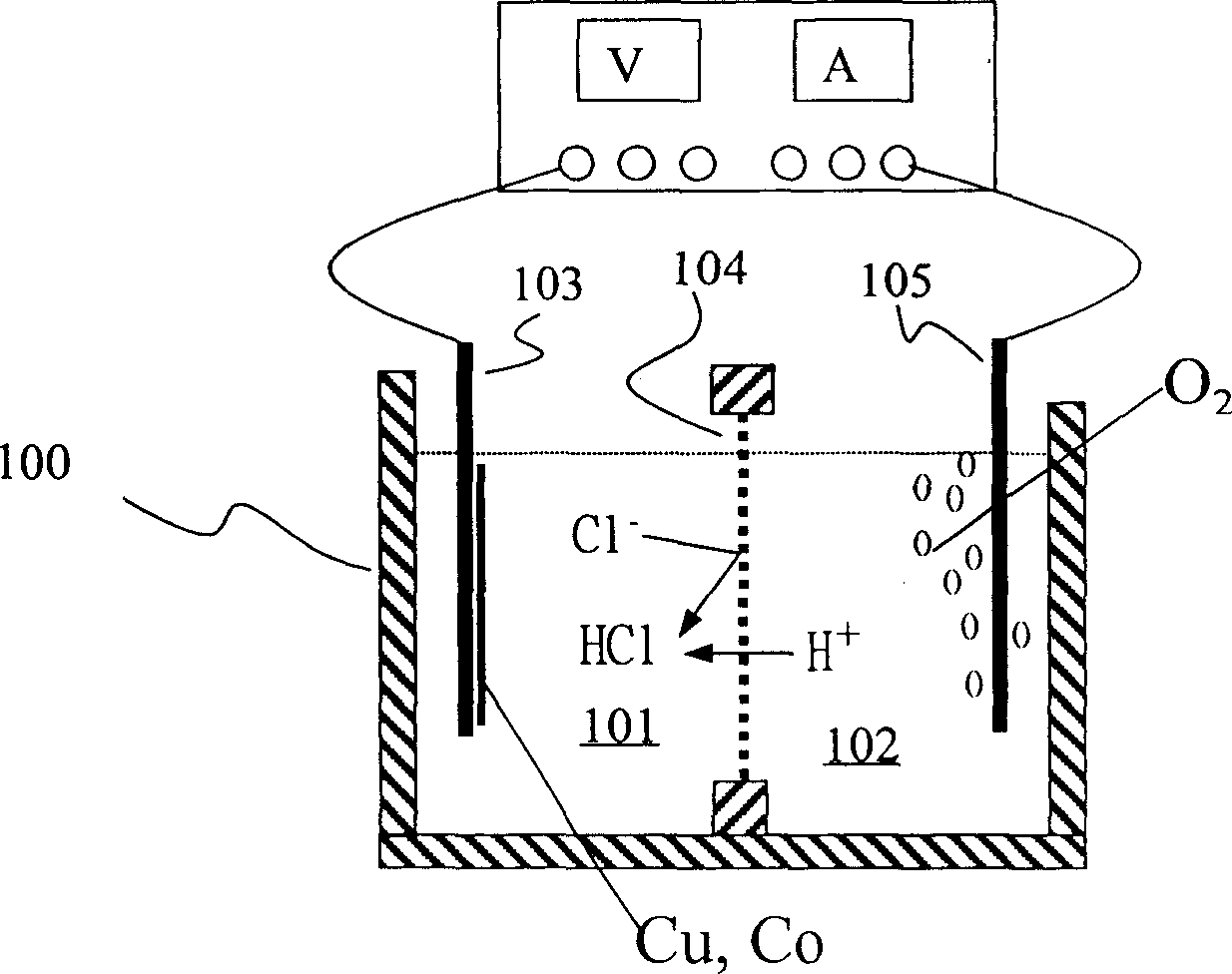

[0037] Put 100 grams of undersize into a mixed solution of 600 ml of sodium chloride and aqueous hydrochloric acid at 80° C., wherein the mixed solution is prepared by adding 100 grams of sodium chloride per liter of aqueous hydrochloric acid using 3N aqueous hydrochloric acid. After 1 hour, the insoluble matter in the mixture was removed by filtration. The filtrate (620ml) is carried out in a diaphragm electrolysis system with DuPont's codenamed Nafion cation exchange membrane to carry out the electrolysis of reclaiming metal copper from the filtrate of this pH less than 0, wherein this filtrate is used as catholyte, 0.1N sodium sulfate The aqueous solution was used as the anolyte, the mesh indium oxide electrode was used as the anode and the 4.5cm×9cm stainless steel mesh electrode was used as the cathode. The diaphragm electrolysis system is at 30°C and 0.01A / cm 2 current density for 10 hours. 4.2 g of copper metal with a purity >99% were obtained. The catholyte after el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com