Waste liquid recovery device and waste liquid recovery method thereof

A waste liquid recovery and waste liquid technology, which is applied in separation methods, deposition adjustment devices, chemical instruments and methods, etc., can solve the problems of suspended solids blocking pipelines, covering a large area, and ordinary grading and sedimentation taking a long time. The effect of recycling and solving pipeline blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

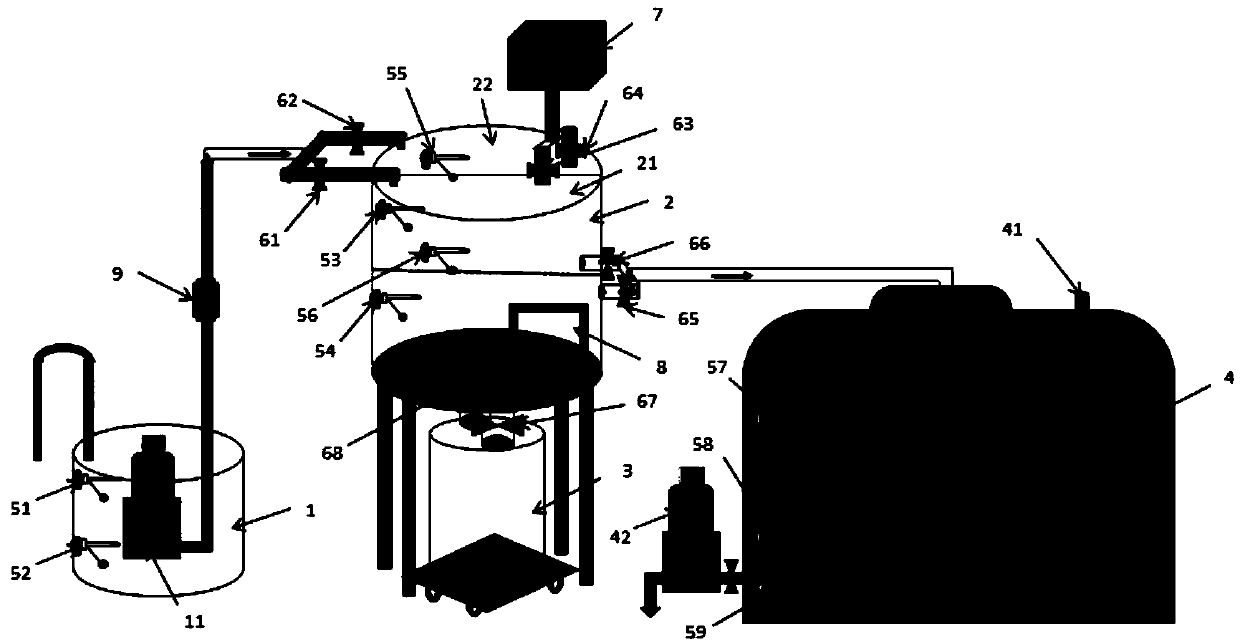

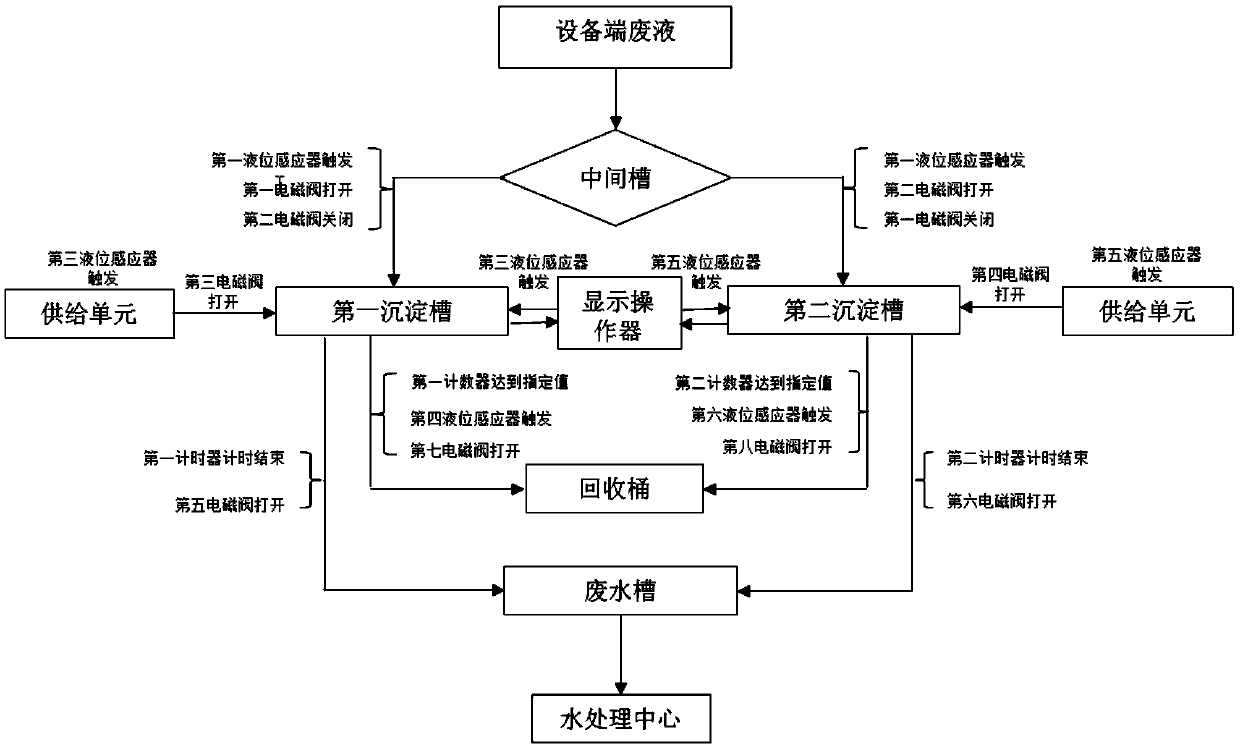

[0031] Waste liquid recycling device of the present invention, as figure 1 As shown, it includes an intermediate tank 1 for collecting waste water, a settling tank 2 for settling waste water, a waste water tank 4 for collecting clear water after waste water settling, and a recovery bucket 3 for collecting waste residue after settling waste water.

[0032] The middle tank 1 communicates with the sedimentation tank 2 through pipelines. The settling tank 2 is a double tank structure, which includes the first settling tank 21 and the second settling tank 22; the first settling tank 21 and the second settling tank 22 are not connected to each other and work independently, and the middle tank 1 is connected with the The first settling tank 21 and the second settling tank 22 are in communication with each other, and the middle tank 1 can be switched to connect or close with the first settling tank 21 or the second settling tank 22 . The settling tank 2 is connected with the recovery...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com