Method for separating dichloromethane, triethylamine and water

A technology of dichloromethane and triethylamine, which is applied in the field of separation of dichloromethane, triethylamine and water, and can solve the problems of flammability, unreported separation method and toxicity of triethylamine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

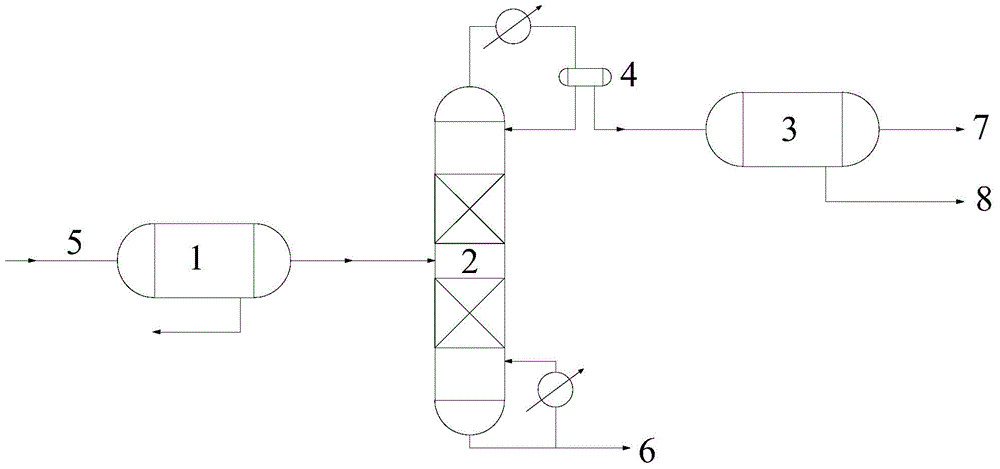

Embodiment 1

[0031] The raw material liquid 5 contains 65% of dichloromethane (mass fraction, the same below), 30% of triethylamine and 5% of water, and the temperature is 20°C. The raw material liquid 5 is first sent into the first phase separation tank 1 under normal pressure. The temperature of the first phase separation tank 1 is 10° C., and the pressure is 101.325 kPa. The stream separated from the upper layer feed liquid of the first phase separation tank 1 is sent to the rectification tower 2, the stream temperature is 20°C, the number of trays in the rectification tower 2 is 24, and the 12th tray from the rectification tower 2 Feed, the top of the tower is the total condenser 4. The total reflux operation is carried out until the top temperature of the rectification tower 2 is 37.4°C, and the extraction starts when the temperature of the bottom of the tower is about 88.0°C, and the reflux ratio is 0.4. In the bottom liquid of rectification tower 2, through chromatographic separat...

Embodiment 2

[0033] The raw material liquid 5 contains 65% of dichloromethane (mass fraction, the same below), 30% of triethylamine and 5% of water, and the temperature is 22°C. The raw material liquid 5 is first sent into the first phase separation tank 1 under normal pressure. The temperature of the first phase separation tank 1 is 25° C., and the pressure is 101.325 kPa. The stream separated from the upper layer feed liquid of the first phase separation tank 1 is sent to the rectification tower 2, the stream temperature is 25°C, the number of trays in the rectification tower 2 is 24, and the 12th tray from the rectification tower 2 Feed, the top of the tower is the total condenser 4. The total reflux operation is carried out until the top temperature of the rectification tower 2 is 37.4°C, and the extraction starts when the temperature of the bottom of the tower is about 88.6°C, and the reflux ratio is 0.3. In the bottom liquid of rectification tower 2, through chromatographic separat...

Embodiment 3

[0035] The raw material liquid 5 contains 65% of dichloromethane (mass fraction, the same below), 30% of triethylamine and 5% of water, and the temperature is 25°C. The raw material liquid 5 is first sent into the first phase separation tank 1 under normal pressure. The temperature of the first phase separation tank 1 is 35° C., and the pressure is 101.325 kPa. The stream separated from the upper layer feed liquid of the first phase separation tank 1 is sent to the rectification tower 2, the stream temperature is 35°C, the number of trays in the rectification tower 2 is 24, and the 12th tray from the rectification tower 2 Feed, the top of the tower is the total condenser 4. The total reflux operation is carried out until the top temperature of the rectification tower 2 is 37.5°C, and the extraction starts when the temperature of the bottom of the tower is about 88.6°C, and the reflux ratio is 1.0. In the bottom liquid of rectification tower 2, through chromatographic separat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com