Ash removal device and steelmaking production line

An ash cleaning device and ash cleaning technology, which are applied in the directions of manufacturing converters, separation of dispersed particles, and improvement of process efficiency, can solve the problems of poor flue gas purification effect, etc. effect of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

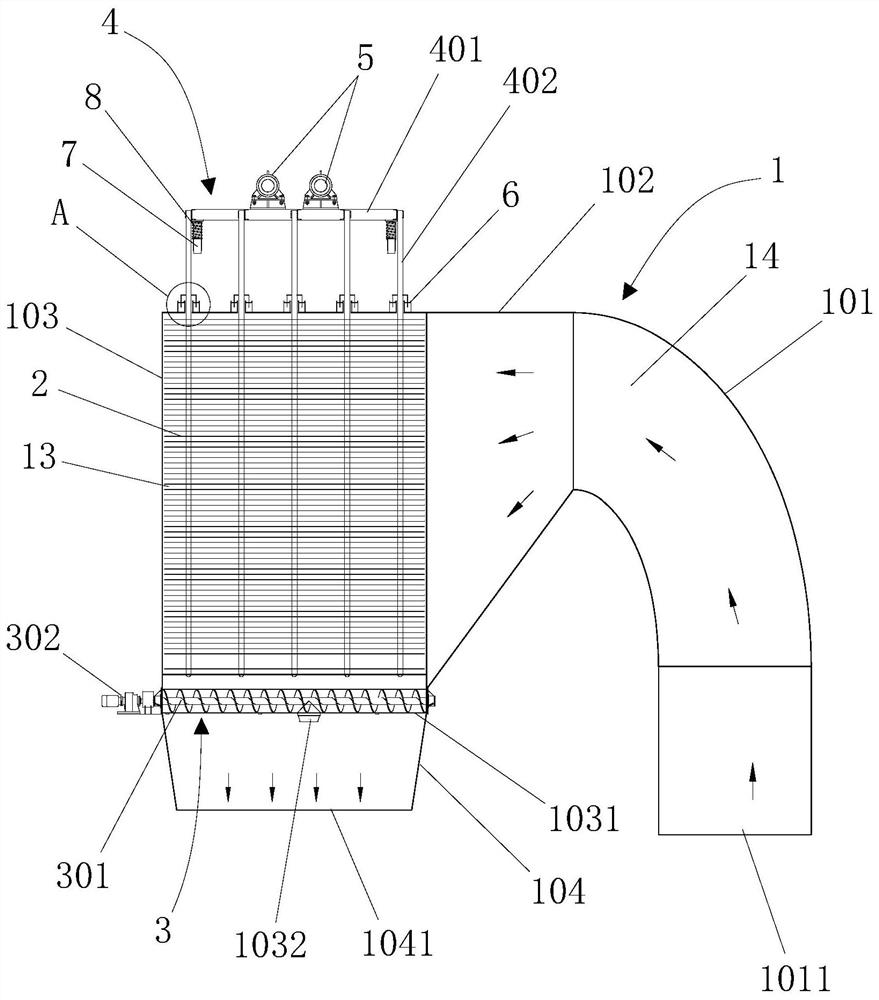

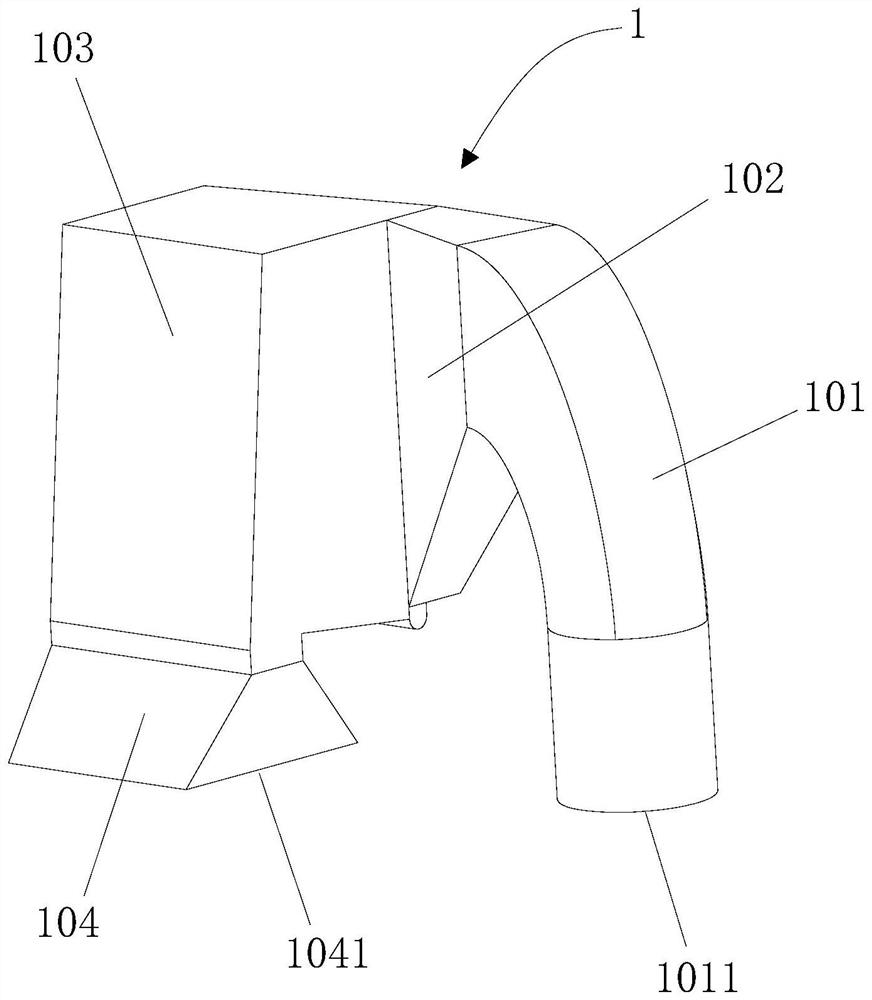

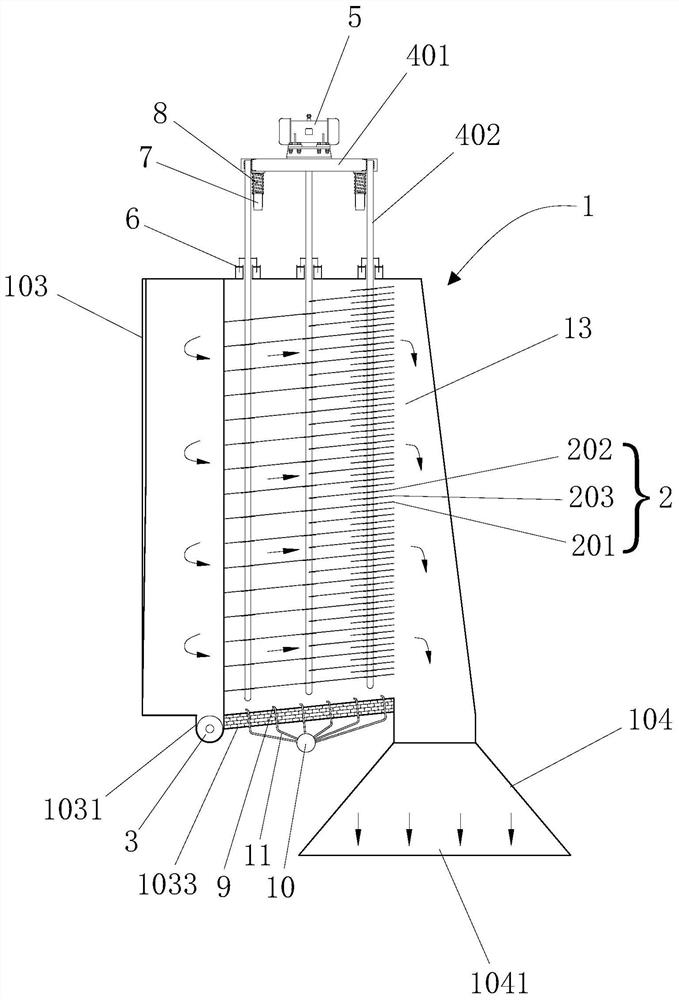

[0063] Such as Figure 1 to Figure 6 As shown, the present invention provides a kind of ash removal device, and this ash removal device comprises housing 1 and a plurality of ash falling boards 2, and each ash falling board 2 is used for carrying out dust (soot or ash) in high temperature flue gas Collecting, wherein: the shell 1 is respectively provided with a flue gas input port 1011 and a flue gas output port 1041, the flue gas input port 1011 is used to connect with the converter steelmaking cooling flue, and the flue gas output port 1041 is used to connect with the high temperature flue gas The recovery equipment is connected, and the housing 1 is formed with a storage chamber 13 for accommodating the ash plates 2 and a flue gas conveying channel 14 capable of transporting high-temperature flue gas. The side end faces are connected, the other end of the flue gas delivery channel 14 is connected to the flue gas input port 1011, and the flue gas output port 1041 is located ...

Embodiment approach 2

[0093] The invention provides a steelmaking production line. The steelmaking production line includes a converter, high-temperature flue gas recovery equipment and the above-mentioned ash removal device. The converter is provided with a converter steelmaking cooling flue, and the high-temperature flue gas outlet of the converter passes through the The cooling flue is connected to the flue gas input port 1011 of the dust removal device, and the flue gas output port 1041 of the dust removal device is connected to the high temperature flue gas recovery equipment.

[0094] The characteristics and advantages of the steelmaking production line of the present invention are:

[0095]The steelmaking production line can smoothly collect the dust in the high-temperature flue gas produced by the converter, achieve the purpose of separating the solid dust in the high-temperature flue gas, and ensure the full purification of the high-temperature flue gas, and the separated The ash slag can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com