Anti-corrosion high-temperature-resistance thermal-insulation composite fabric for protective clothing

A technology of high temperature resistance and protective clothing, applied in the field of textile fabrics, can solve the problems of being unsuitable for corrosive workplaces, etc., and achieve the effects of long service life, health protection, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

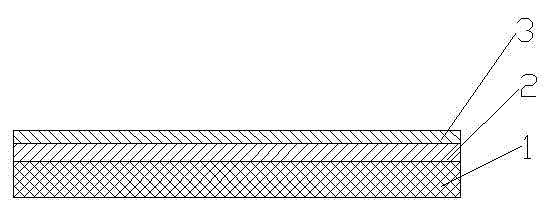

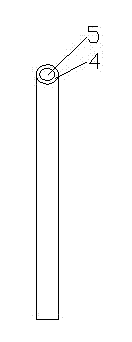

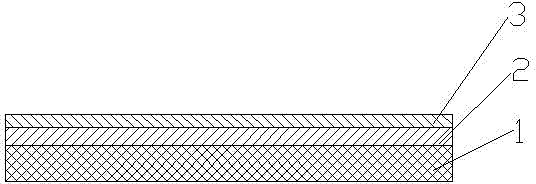

[0020] In the core-spun yarn, the core yarn 5 is made of glass fiber filaments, and the covering fiber 4 is made of flame-retardant acrylic fibers and flame-retardant viscose fibers. First, the flame-retardant acrylic fiber and flame-retardant viscose fiber are woven into a blended yarn, and then the blended yarn is tightly wound outside a glass fiber filament to make a core-spun yarn, and finally the warp and weft of the core-spun yarn are interwoven into a fabric base fabric 1.

Embodiment 2

[0022] In the core-spun yarn, the core yarn 5 is made of chemical fiber filament, and the covering fiber 4 is made of aramid fiber and flame-retardant cotton. First, aramid fiber and flame-retardant cotton are blended to obtain a blended yarn, and then the blended yarn is tightly wound on the outside of two chemical fiber fibers to form a core-spun yarn, and finally the warp and weft of the core-spun yarn are interwoven into a fabric base fabric 1 .

[0023] The corrosion-resistant, high-temperature, and heat-insulating composite protective clothing fabric disclosed by the present invention has good hand feeling, high strength, wear resistance, corrosion resistance, high temperature resistance, good heat insulation performance, and long service life. The surface of the base fabric 1 yarn does not contain glass fiber , to maximize the protection of the wearer's health.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com