Preparation method of fluorine-containing acrylic acid super-hydrophobic coating

A technology of super-hydrophobic coating and fluorine-containing acrylic acid, applied in the direction of polyurea/polyurethane coating, coating, etc., can solve the problems that the waterproof and anti-corrosion performance needs to be improved, the effect is not particularly ideal, and the production cost is high, and achieve excellent super-hydrophobic performance, Application prospect and potential, low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

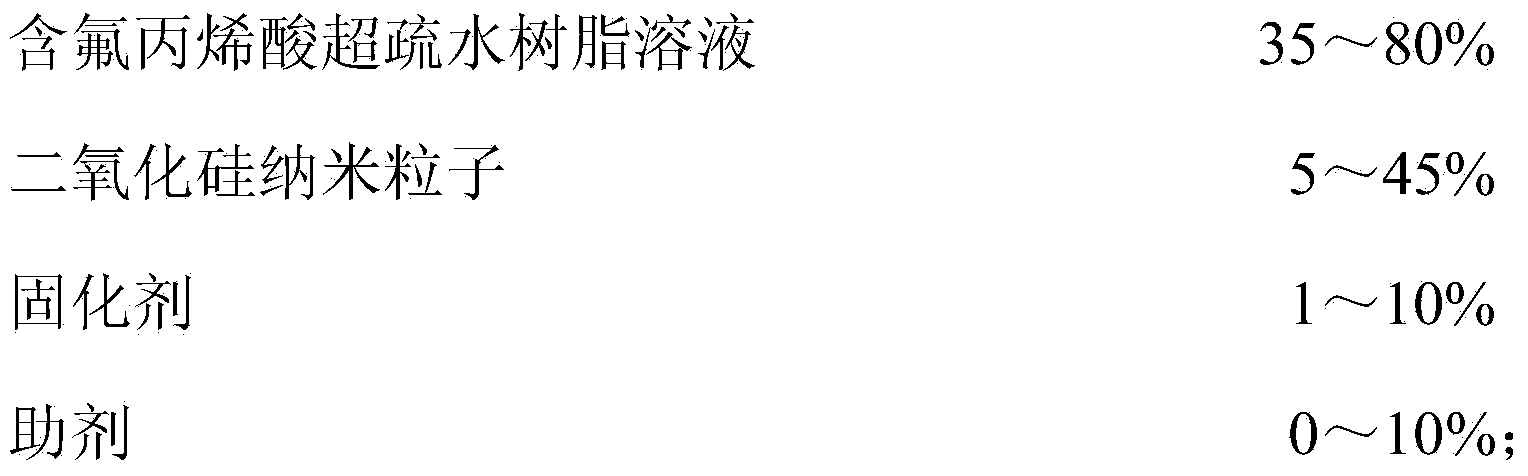

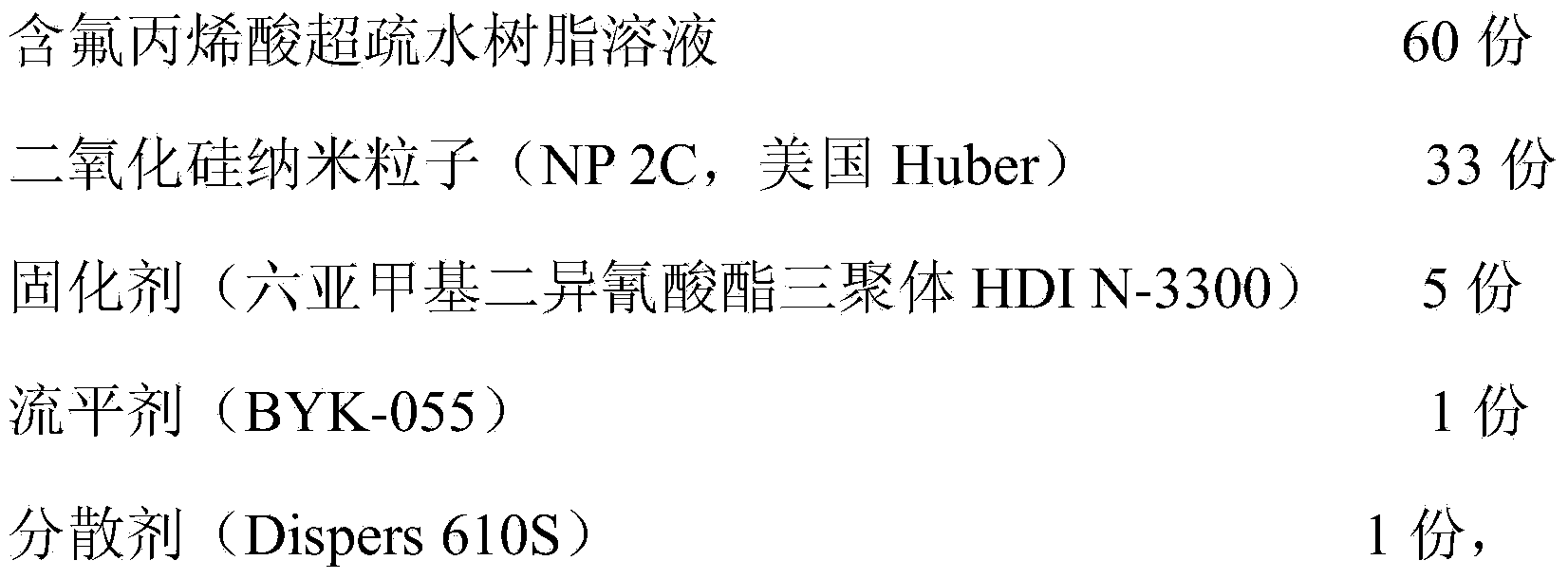

[0028] A raw material formula of fluorine-containing acrylic acid superhydrophobic coating is as follows:

[0029]

[0030] Fluorine-containing acrylic acid superhydrophobic resin solution is prepared according to the following method:

[0031] (1) Use a mixed solvent of butyl acetate and xylene with a volume ratio of 3:1 as the reaction medium, keep the stirring speed at 600 rpm, and control the reaction temperature at 80°C.

[0032] (2) At room temperature, benzoyl peroxide (BPO), styrene (St), methyl methacrylate (MMA), stearyl methacrylate (SMA), 2-hydroxyethyl methacrylate (HEMA), fluorine-containing acrylic monomer perfluoroalkyl ethyl acrylate (FMA) monomer mixed evenly.

[0033] Among them, BPO accounts for 1% of the total mass of all mixed monomers; St:MMA:SMA:HEMA is 6:2:4:1, and the total mass fraction of St, MMA, SMA and HEMA in the mixed solvent reaction medium is 20% ; The mass fraction of FMA in the mixed solvent reaction medium is 10%.

[0034] (3) Drop t...

Embodiment 2

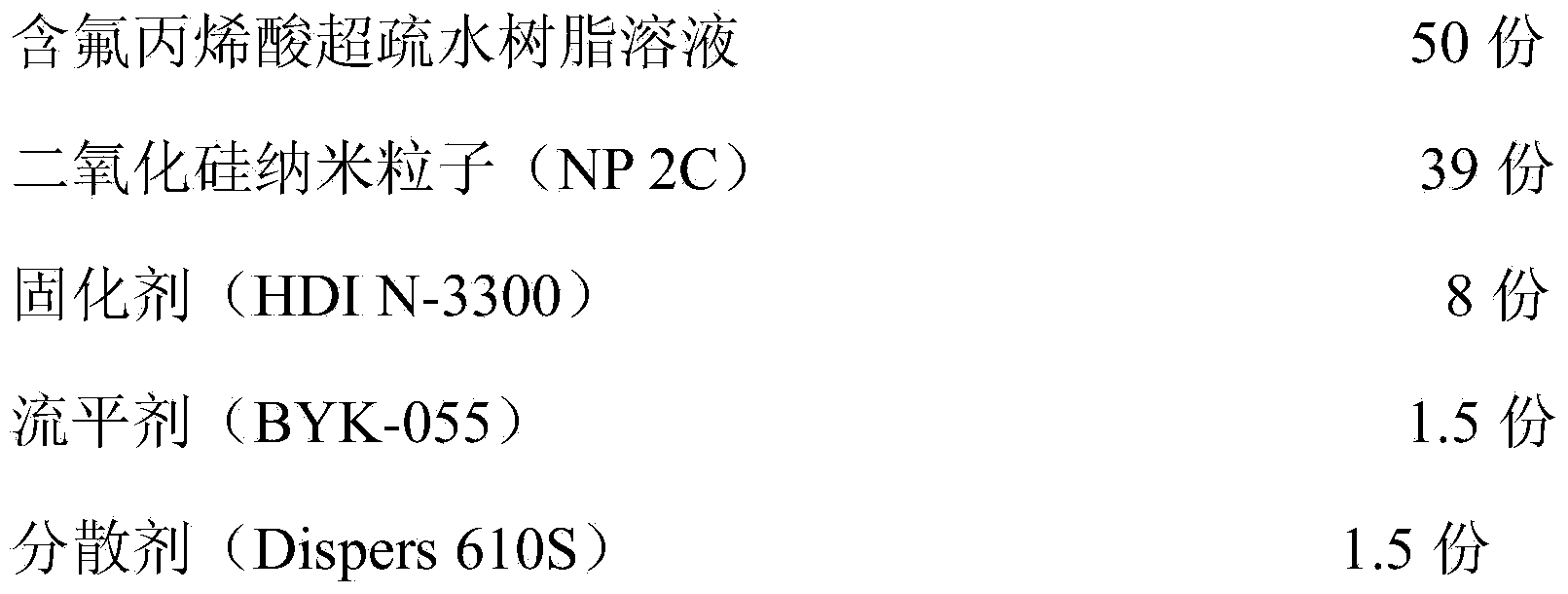

[0036] A raw material formula of fluorine-containing acrylic acid superhydrophobic coating is as follows:

[0037]

[0038] Fluorine-containing acrylic acid superhydrophobic resin solution is prepared according to the following method:

[0039](1) Use a mixed solvent of butyl acetate and xylene with a volume ratio of 3:1 as the reaction medium, keep the stirring speed at 600 rpm, and control the reaction temperature at 80°C.

[0040] (2) At room temperature, benzoyl peroxide (BPO), styrene (St), methyl methacrylate (MMA), stearyl methacrylate (SMA), 2-hydroxyethyl methacrylate (HEMA), fluorine-containing acrylic monomer perfluoroalkyl ethyl acrylate (FMA) monomer mixed evenly.

[0041] Among them, BPO accounts for 1.5% of the total mass of all mixed monomers; St:MMA:SMA:HEMA is 5:2:3:1, and the total mass fraction of St, MMA, SMA and HEMA in the mixed solvent reaction medium is 25%. ; The mass fraction of FMA in the mixed solvent reaction medium was 8%.

[0042] (3) Drop...

Embodiment 3

[0044] A raw material formula of fluorine-containing acrylic acid superhydrophobic coating is as follows:

[0045] Fluorine-containing acrylic superhydrophobic resin solution 10 parts

[0046] Silica nanoparticles (NP2C) 5 parts

[0047] Curing agent (HDI N-3300) 1 part

[0048] Fluorine-containing acrylic acid superhydrophobic resin solution is prepared according to the following method:

[0049] (1) Use a mixed solvent of butyl acetate and xylene with a volume ratio of 3:1 as the reaction medium, keep the stirring speed at 100 rpm, and control the reaction temperature at 70°C.

[0050] (2) At room temperature, benzoyl peroxide (BPO), styrene (St), methyl methacrylate (MMA), stearyl methacrylate (SMA), 2-hydroxyethyl methacrylate (HEMA), fluorine-containing acrylic monomer perfluoroalkyl ethyl acrylate (FMA) monomer mixed evenly.

[0051] Among them, BPO accounts for 0.1% of the total mass of all mixed monomers; St:MMA:SMA:HEMA is 5:2:1:1, and the total mass fraction of S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com