Recovery method for leftover and residue of positive electrode of lithium ion battery

A secondary battery and recovery method technology, applied in the field of recycling and reuse of active materials, can solve the problems of battery manufacturers such as loss of economic benefits, no memory effect, environmental pollution, etc., to avoid economic losses, low production costs, and significant economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

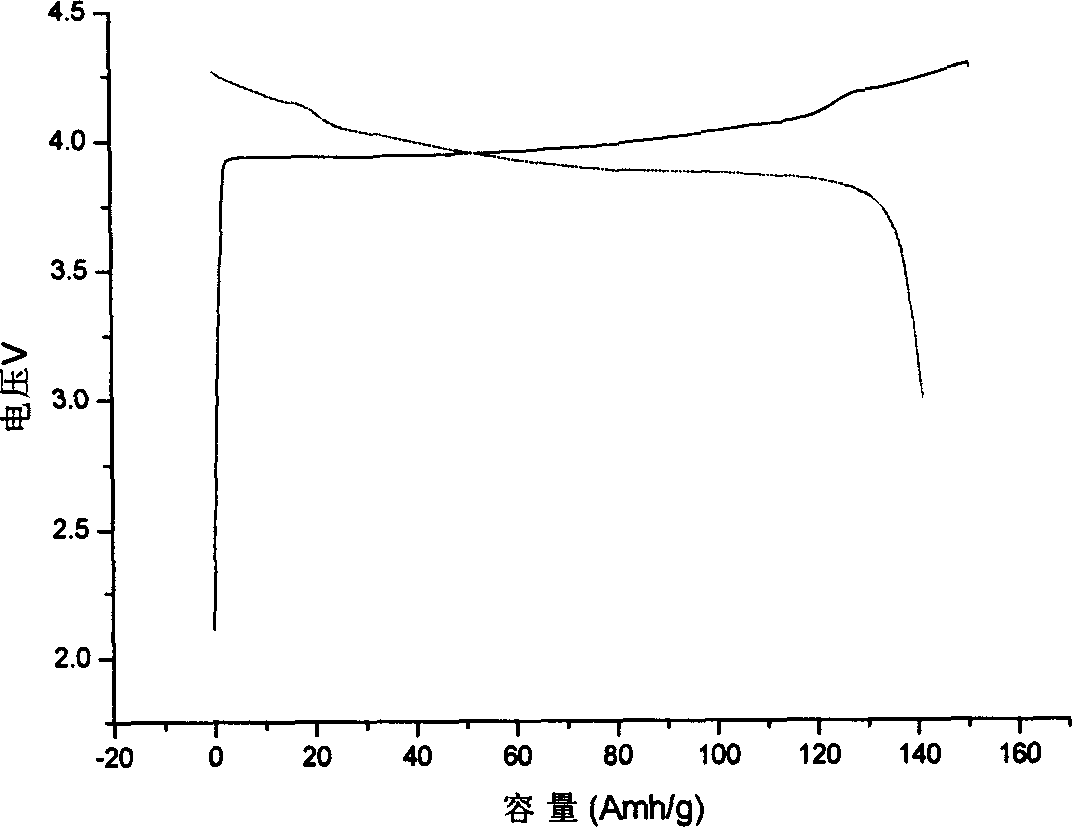

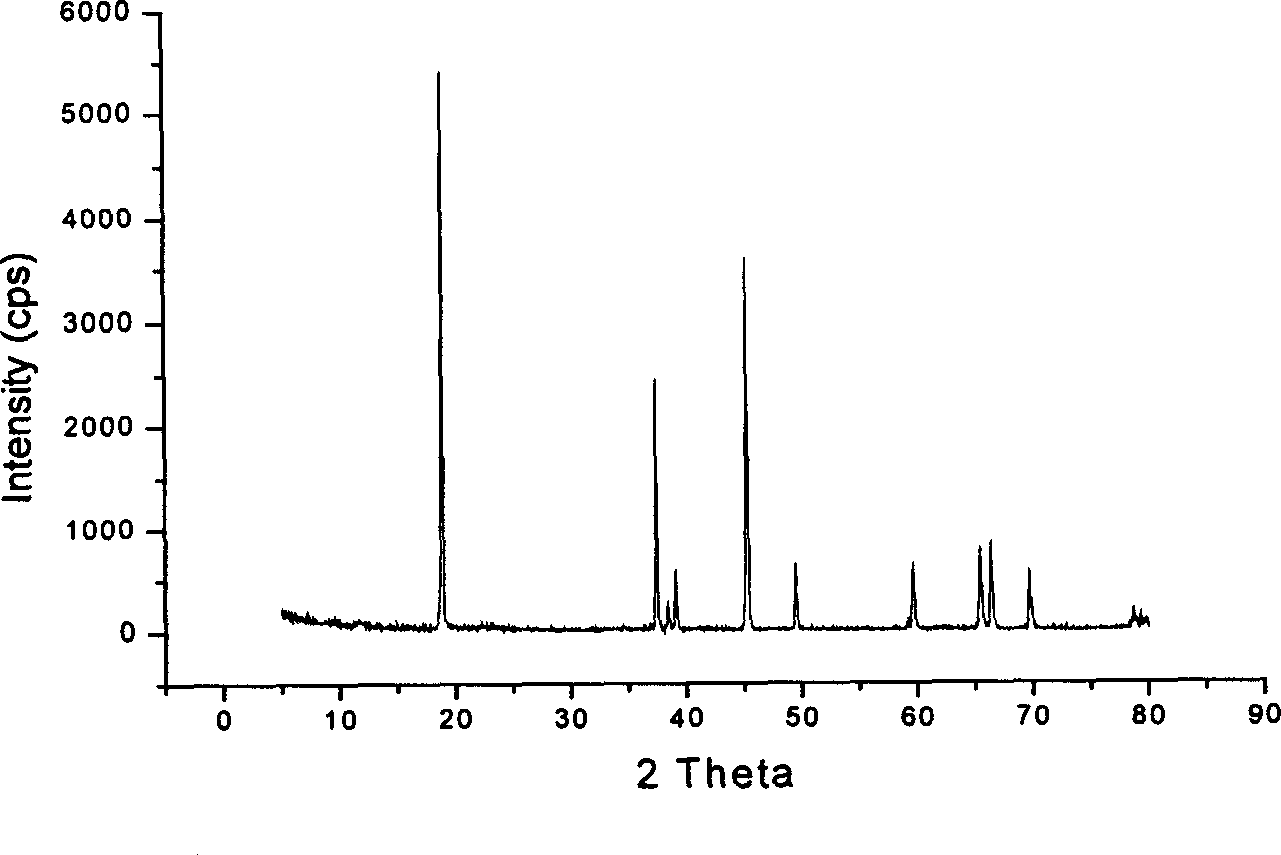

[0020] Take 200g of positive electrode leftovers based on aluminum foil, after mechanical crushing, soak in 1000mL N-methylpyrrolidone solution at room temperature for one day, then raise the temperature to 140°C, and use mechanical stirring to make the active material LiCoO 2 , conductive agent, binder and matrix separation. Stand still, decant out the upper layer solution, wash the lower layer sediment with water several times, remove part of the water-soluble binder and conductive agent, and dry the product obtained after separation in the air at 100°C, the mixed mass is 150g, and use mechanical flotation The carbon black and insoluble binder were removed by the method, and the mixture was calcined at 850° C. for 6 hours to obtain 110 g of active material, accounting for 73.3% of the mass of the above mixture. The XRD structure diagram of the product obtained is as follows figure 1 . The recovered active material is used as the positive electrode material, and lithium met...

Embodiment 2

[0022] After mechanical crushing, 30g of positive electrode scraps and scraps based on aluminum foil were soaked in 1000mL dimethylacetamide at room temperature (20°C) for one day, and then the temperature was controlled at 100°C to make the active material LiCoO 2 , conductive agent, binder and matrix separation. Stand still, decant out the upper layer solution, wash the lower sediment with distilled water several times, remove part of the water-soluble binder and conductive agent, then decant out the distilled water, and dry it in the air at 100°C. The mixed mass is 23g. The selection method removes carbon black and insoluble binder, and bakes at 850°C for 6 hours to obtain 18g of active material, accounting for 78.3% of the mass of the above mixture. The XRD test result of gained product and figure 1 same. The recovered active material was used as the positive electrode material, metal lithium was used as the counter electrode, and a button battery was prepared, charged a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com