Laminated adhesive aluminium foil band and it mfg. process

A technology of aluminum foil tape and manufacturing method, which is applied in the field of aluminum foil tape, can solve the problems of high cost, waste of resources, and low utilization rate, and achieve the effects of low cost, high utilization rate, convenient use and

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

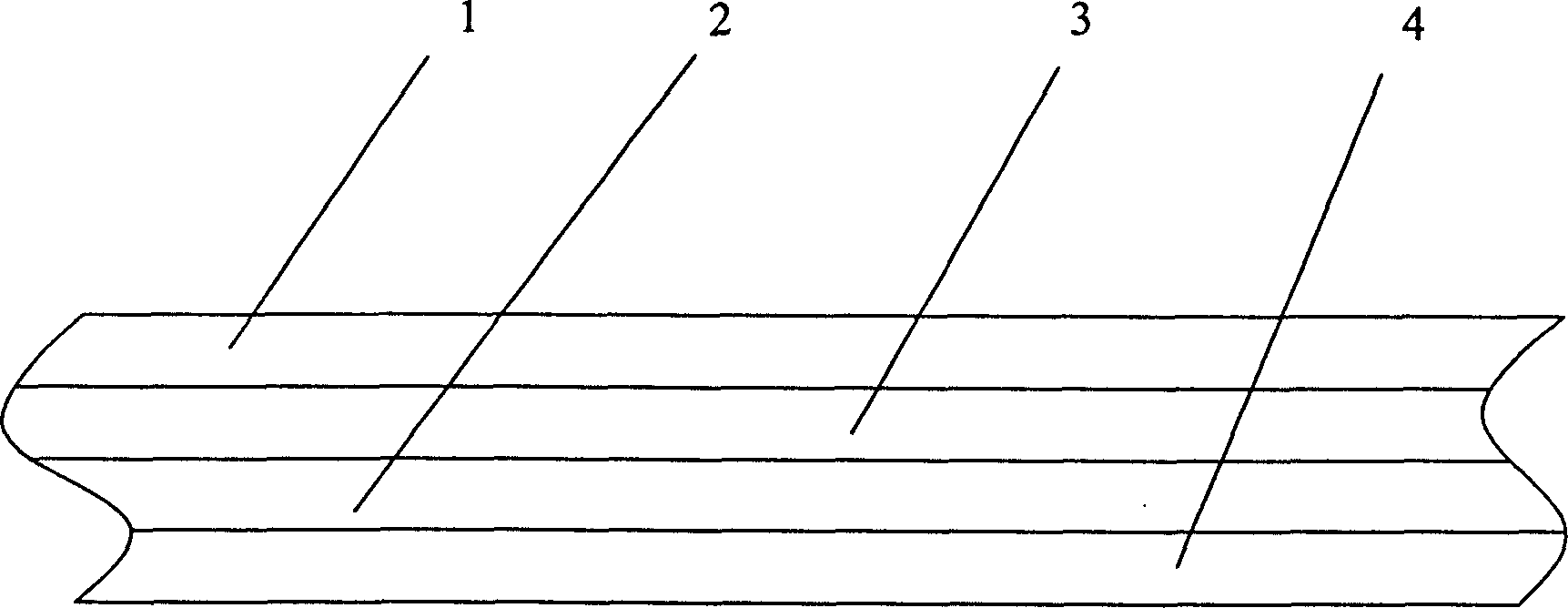

[0014] Such as figure 1 As shown, the said laminated aluminum foil adhesive tape of the present invention is provided with plastic film layer 1 and aluminum foil layer 2, oily glue is coated on the upper surface of plastic film layer 1, adopts glue roller to apply glue, after 5m drying tunnel, drying tunnel The temperature is 80° C., and then the pre-pressing roller and then the pressure roller. The temperature of the pressure roller is 80° C. and the speed is 10 m / min to form the intermediate rubber layer 3 . Put the aluminum foil layer 2 on the intermediate adhesive layer 3, and apply water-based adhesive on the bottom surface of the aluminum foil layer 2 to form the bottom adhesive layer 4, which is to make a laminated aluminum foil tape. Process the laminated aluminum foil tape into a laminated aluminum foil tape roll.

[0015] The thickness of the aluminum foil layer 2 is 4 μm; the thickness of the plastic film layer 1 is 10 μm; the thickness of the intermediate adhesive...

Embodiment 2

[0017] Similar to Example 1, the difference is that the steps of processing the laminated aluminum foil tape are as follows: apply water-based laminated glue on the upper surface of the plastic film layer 1, apply glue with a glue roller, and then pass through an 8m drying tunnel with a temperature of 90 ℃, and then go through the pre-compression roller to the pressure roller, the temperature of the pressure roller is 90 ℃, and the speed is 30m / min to form the intermediate rubber layer 3. Put the aluminum foil layer 2 on the intermediate adhesive layer 3, and apply oily glue on the bottom surface of the aluminum foil layer 2 to form the bottom adhesive layer 4, which is to make a laminated aluminum foil tape. Process the laminated aluminum foil tape into a laminated aluminum foil tape roll.

[0018] The thickness of the aluminum foil layer is 10 μm; the thickness of the plastic film layer is 25 μm; the thickness of the middle adhesive layer is 15 μm, and the thickness of the b...

Embodiment 3

[0020] Similar to Example 1, the difference is that the steps of processing the laminated aluminum foil tape are as follows: apply water-based glue on the upper surface of the plastic film layer 1, use a glue roller to apply glue, and then pass through a 10m drying tunnel with a temperature of 100°C. Then go through the pre-pressing roller and then go to the pressure roller. The temperature of the pressure roller is 100° C. and the speed is 25 m / min to form the intermediate rubber layer 3 . An aluminum foil layer 2 is placed on the intermediate adhesive layer 3, and a pressure-sensitive adhesive is coated on the bottom surface of the aluminum foil layer 2 to form a bottom adhesive layer 4, which is then made into a laminated aluminum foil tape. Process the laminated aluminum foil tape into a laminated aluminum foil tape roll.

[0021] The thickness of the aluminum foil layer is 15 μm; the thickness of the plastic film layer is 4 μm; the thickness of the middle adhesive layer i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com