Aluminium alloy foil for lithium ion battery positive current collector and manufacturing method thereof

A technology for positive current collectors and lithium-ion batteries, applied in the direction of electrode carriers/collectors, etc., can solve the problems of rising resistivity, increasing the internal resistance of lithium-ion batteries, reducing the input energy of lithium-ion batteries, etc., to achieve lower resistivity, high The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

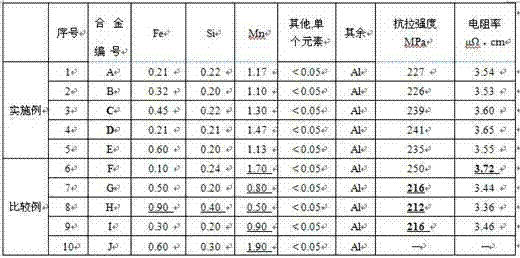

Examples

Embodiment 6

[0053] In Example 6, the resistivity exceeds the scope of the present invention because the Mn content exceeds the upper limit.

[0054] In Examples 7, 8, and 9, because the content of Mn element is lower than the lower limit, the strengthening effect of Mn element is insufficient, and cannot meet the strength requirement of the present invention.

Embodiment 10

[0055] In Example 10, since the Mn content exceeded the upper limit, the strength was too high, the rollability of the aluminum foil was lowered, and an aluminum foil of 5 to 30 μm could not be rolled.

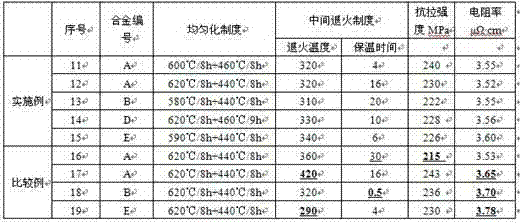

[0056] Table 2 is the evaluation of the manufacturing method, as follows:

[0057] In the embodiment, the homogenization annealing and intermediate annealing processes of serial numbers 11-15 are within the scope of the present invention, so the tensile strength and elongation meet the requirements of the present invention. On the other hand, serial number 16-19 in the comparative example does not satisfy the scope of the present invention, so cause following result:

Embodiment 25

[0074] In Example 25, the resistivity exceeded the range of the present invention because the Mn content exceeded the upper limit.

[0075] Examples 26, 27, and 28 cannot meet the strength requirements of the present invention because the content of Mn element is lower than the lower limit, and the strengthening effect of Mn element is insufficient.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com