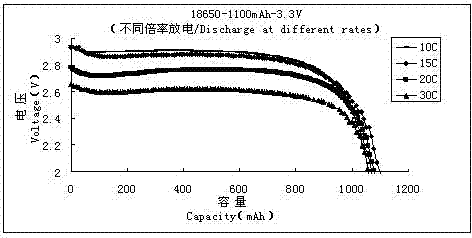

High rate lithium iron phosphate cell and preparation method thereof

A lithium iron phosphate battery and lithium iron phosphate technology, applied in the manufacture of electrolyte batteries, battery electrodes, secondary batteries, etc., can solve the problems of poor high-rate discharge and poor safety, and achieve improved consistency, improved safety, and improved The effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Preparation of positive electrode: the active material has a specific surface area of 25m 2 / g lithium iron phosphate, the conductive agent is conductive carbon black Super-P, KS-6 is conductive graphite, the binder is polyvinylidene fluoride PVDF5130, nitrogen methylpyrrolidine (NMP) is the solvent, and the viscosity of the positive electrode slurry is controlled It is 3000~15000mPas. The percentages of various substances in the slurry are: LiFePO 4 :Super-P:KS-6:PVDF5130:NMP=89:4:2:5:115. First, dissolve PVDF5130 in NMP, then add the pre-mixed lithium iron phosphate, conductive graphite and conductive carbon black, and mechanically stir at high speed for 3 hours for pre-dispersion (1800r / min), and then use mechanical high-speed stirring (1500r / min) Combined with ultrasonic stirring (pressure 10MPa, ultrasonic frequency 20KHz) for 3 hours, the slurry is vacuum defoamed and then coated, using aluminum foil with a thickness of 20μm, after drying, rolling, and slittin...

Embodiment 2

[0048] Prepare the positive electrode: the active material has a specific surface area of 24m 2 / g lithium iron phosphate, the conductive agent is conductive carbon black Super-P, KS-6L is conductive graphite, the binder is polyvinylidene fluoride PVDF761A, nitrogen methylpyrrolidine (NMP) is the solvent, and the viscosity of the positive electrode slurry is controlled It is 3000~15000mPas. The percentages of various substances in the slurry are: LiFePO 4 :Super-P:KS-6:PVDF5130:NMP=88:4:2:6:115. First, dissolve PVDF761A in NMP, then add the pre-mixed lithium iron phosphate, conductive graphite and conductive carbon black, and mechanically stir at high speed for 3 hours for pre-dispersion (1800r / min), and then use mechanical high-speed stirring (1600r / min) Combined with ultrasonic stirring (pressure 11MPa, ultrasonic frequency 20KHz) for 2.5 hours, the slurry is vacuum defoamed and then coated, using aluminum foil with a thickness of 20μm, after drying, rolling, and slittin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com