Method and device for oxidizing sulphite grout in wet flue gas desulfurization process

A wet flue gas desulfurization and sulfite technology, which is applied in the direction of sulfate/bisulfate preparation, ammonium sulfate, sulfate preparation, etc., can solve the problem of increased equipment cost, ozone loss, and increased volume of desulfurization towers, etc. problems, to achieve the effect of improving oxidation efficiency and oxidation rate, increasing service life, and increasing conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to the following embodiments.

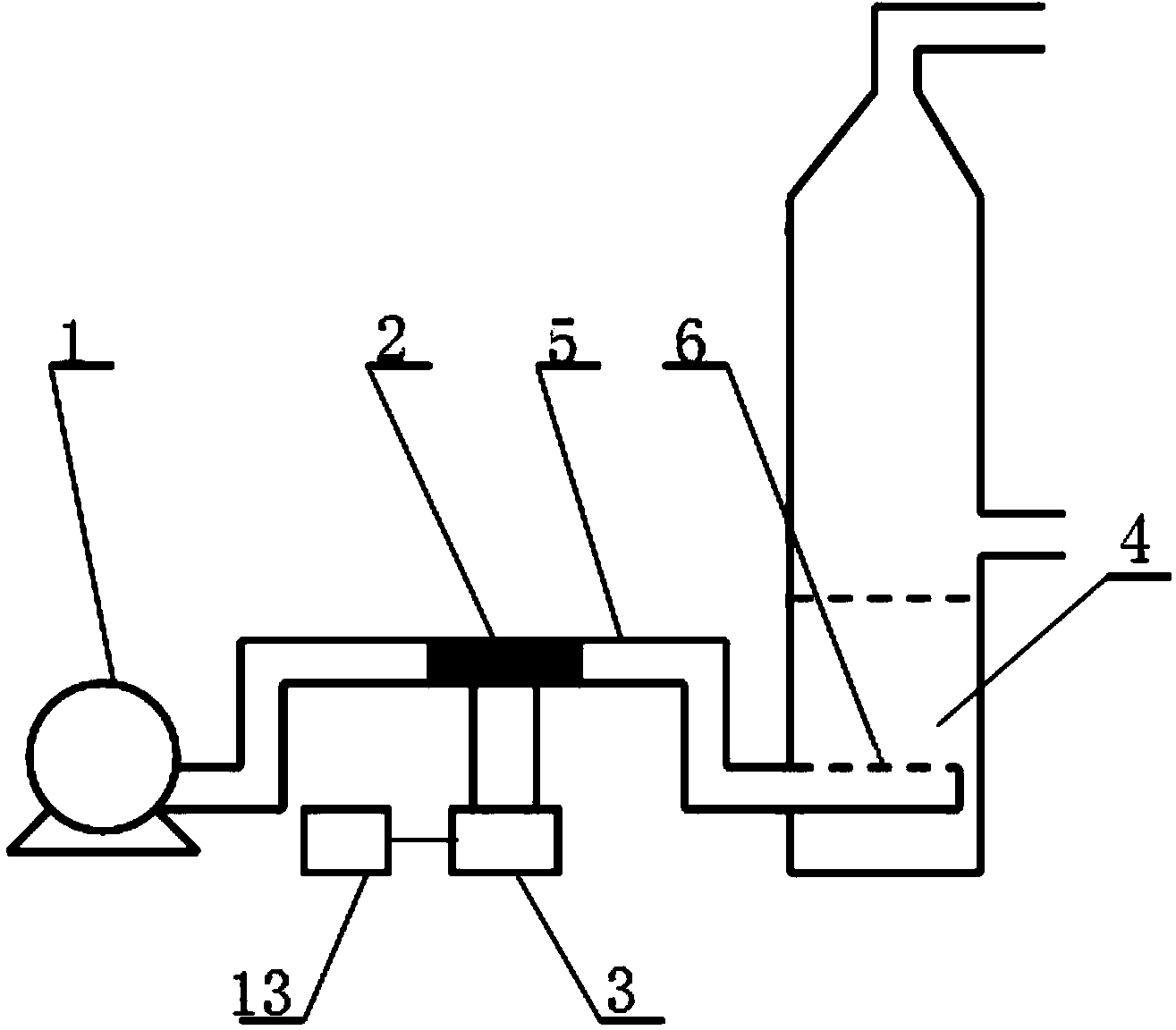

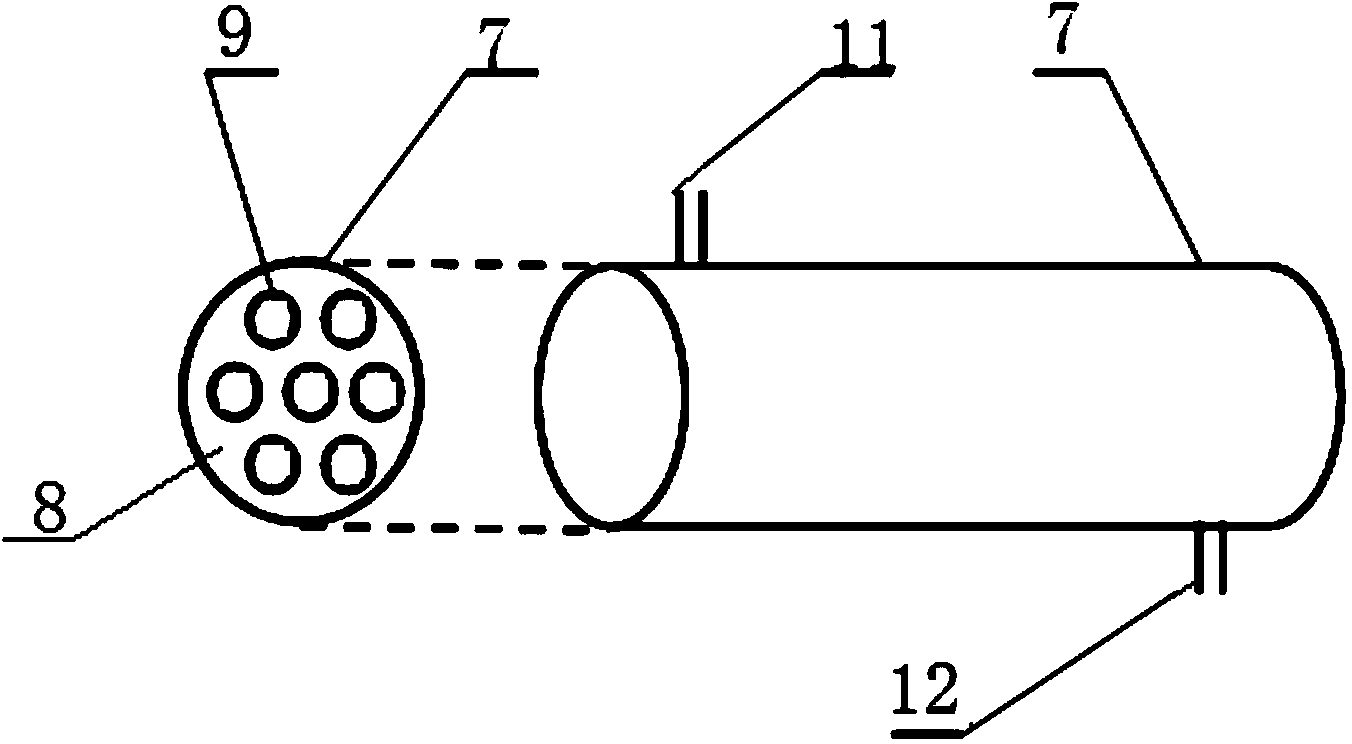

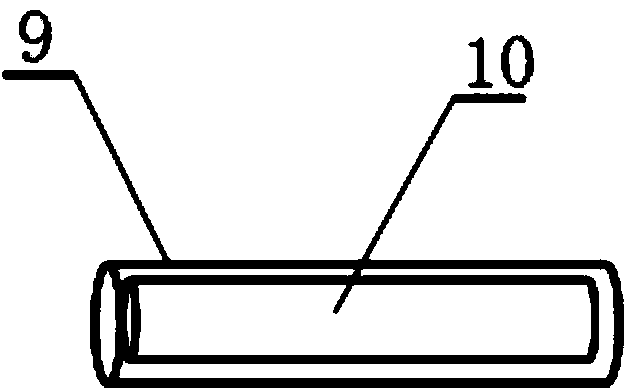

[0030] figure 1The sulfite slurry oxidation equipment in the wet flue gas desulfurization process shown includes an air supply fan 1, a surface discharge reactor 2, an AC high-voltage power supply 3 and a reaction pool. The reaction pool is the sulfite slurry pool 4 in the lower section of the desulfurization tower. The bottom of the slurry pool 4 is provided with an air distributor 6, the creeping discharge reactor 2 is electrically connected to the AC high-voltage power supply 3, the outlet end of the air supply fan 1 is connected to the intake end of the creeping discharge reactor 2, and the creeping discharge reactor 2 The gas outlet is connected to one end of the gas outlet pipe 5, and the other end of the gas outlet pipe 5 extends into the sulfite slurry pool 4 in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com