Supercapacitor electrode corrosion-resistant conductive coating

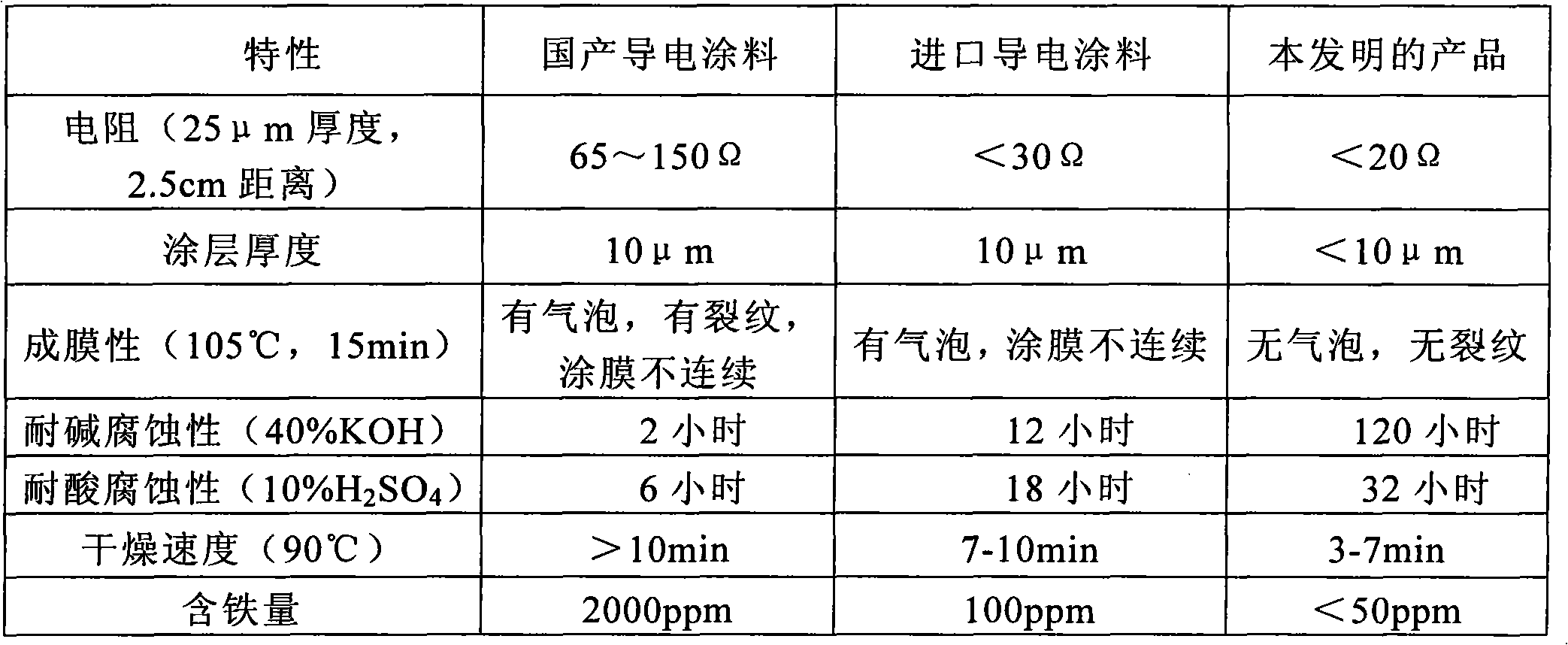

A supercapacitor, anti-corrosion and conductive technology, applied in the direction of anti-corrosion coatings, conductive coatings, capacitors, etc., can solve the problems of acid and alkali corrosion resistance, narrow use margin, slow drying speed, etc., to prevent corrosion, increase surface area, dry fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] 1) Formulation:

[0051] Graphite 22wt%

[0052] Sodium carboxymethylcellulose 2.0wt%

[0053] Colloidal silicon dioxide 8.3wt%

[0054] Neutralizing amine 2.5wt%

[0055] Pure water 65.2wt%

[0056] The particle size of graphite in the above formula is less than 3 μm, wherein the particle size between 0.1-2 μm accounts for 48-55 wt % of the total graphite, and the particle size smaller than 0.1 μm accounts for 28-35 wt % of the total graphite.

[0057] 2) Preparation:

[0058] The above components are fully mixed, stirred evenly, added to a ball mill to debond and disperse, and after discharging, the supercapacitor electrode anti-corrosion conductive coating of the present invention is obtained. After testing, its performance parameters are as follows: solid content: 28.9wt%, viscosity (20±1°C), 72Pa.s, pH value: 8.50, relative density, 1.12g / cm 3 , 2.5cm interval average resistance 7Ω. Alkali resistance test: soak for 120 hours without foaming, peeling, corrosi...

Embodiment 2

[0060] 1) Formulation:

[0061] Carbon black 25wt%

[0062] -190 3.0wt%

[0063] Colloidal alumina 12wt%

[0064] Neutralizing amine 3.0wt%

[0065] Pure water 57wt%

[0066] The particle size of carbon black in the above formulation is less than 3 μm, wherein the particle size of 0.1-2 μm accounts for 48-55 wt % of the total carbon black, and the particle size of less than 0.1 μm accounts for 28-35 wt % of the total carbon black.

[0067] 2) Preparation:

[0068] The preparation method is the same as in Example 1. After testing, the performance parameters of the obtained supercapacitor electrode anti-corrosion conductive coating are as follows: solid content: 28.6wt%, viscosity (20±1°C), 73Pa.s, pH value is 8.20, relative density, 1.12g / cm 3 , 2.5cm interval average resistance 6Ω. Alkali resistance test: soak for 120 hours without foaming, peeling, corrosion, etc.; acid resistance test: soak for 32 hours without foaming, peeling, corrosion, etc.

Embodiment 3

[0070] 1) Formulation:

[0071] Activated carbon 24wt%

[0072] Sodium lignosulfonate 2.8wt%

[0073] Styrene Acrylic Emulsion 12wt%

[0074] Neutralizing amine 2.3wt%

[0075] Pure water 58.9wt%

[0076] The particle size of activated carbon in the above formula is less than 3 μm, wherein the particle size of 0.1-2 μm accounts for 48-55 wt % of the total activated carbon, and the particle size of less than 0.1 μm accounts for 28-35 wt % of the total activated carbon.

[0077] 2) Preparation:

[0078] The preparation method is the same as in Example 1. After testing, the performance parameters of the obtained supercapacitor electrode anti-corrosion conductive coating are as follows: solid content: 28.8wt%, viscosity (20±1°C), 75Pa.s, pH value is 8.60, relative density, 1.12g / cm 3 , 2.5cm interval average resistance 8Ω. Alkali resistance test: soak for 120 hours without foaming, peeling, corrosion, etc.; acid resistance test: soak for 32 hours without foaming, peeling, c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com