Plasma generation system by tubular dielectric barrier discharge and application thereof

A technology of dielectric barrier discharge and plasma, which is applied in the direction of plasma, electrical components, separation methods, etc., can solve the problems of partial discharge, obvious thermal effect, poor adaptability, etc., achieve uniform distance between electrodes, uniform air flow distribution, and avoid corrosion problems Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

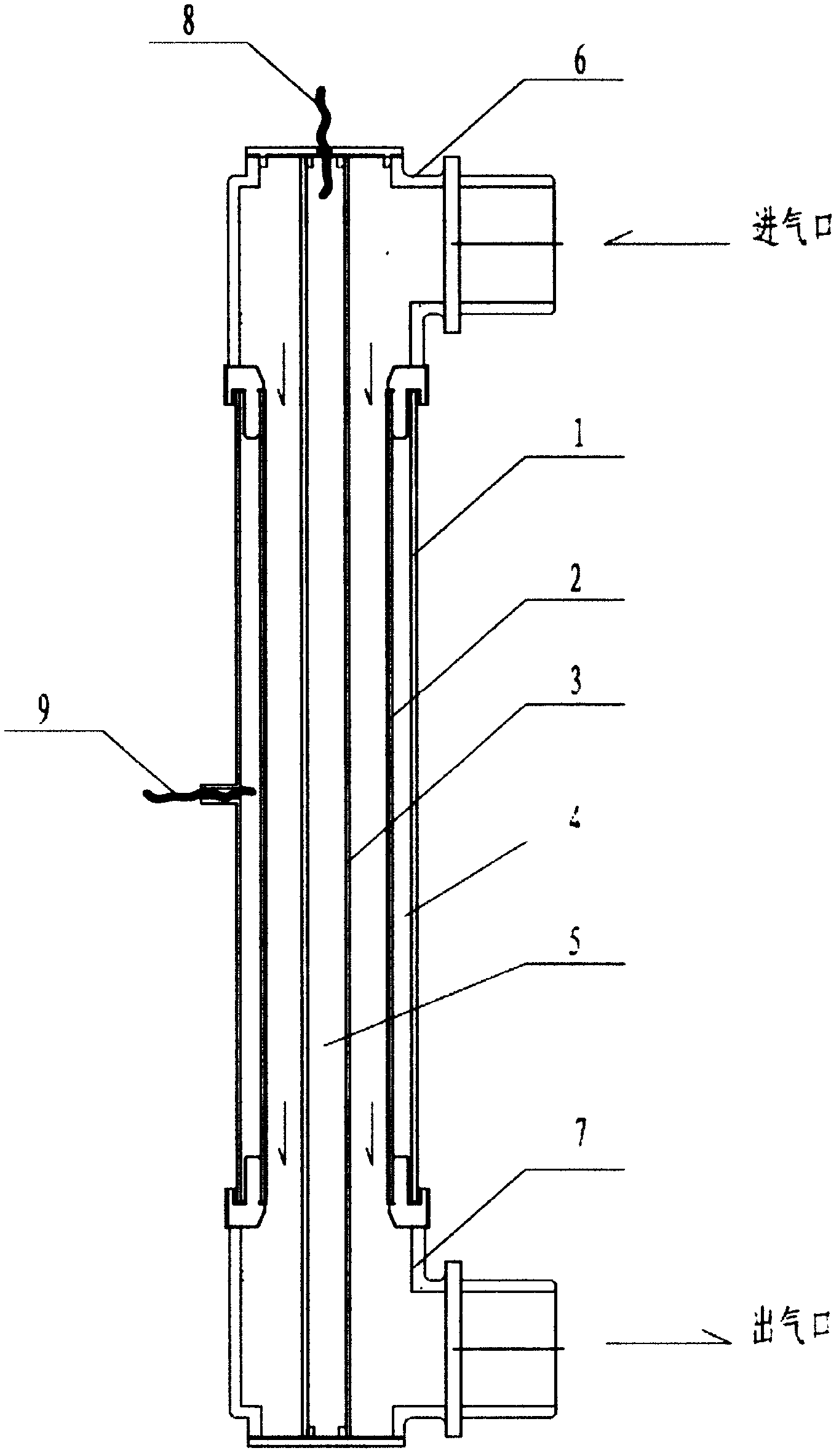

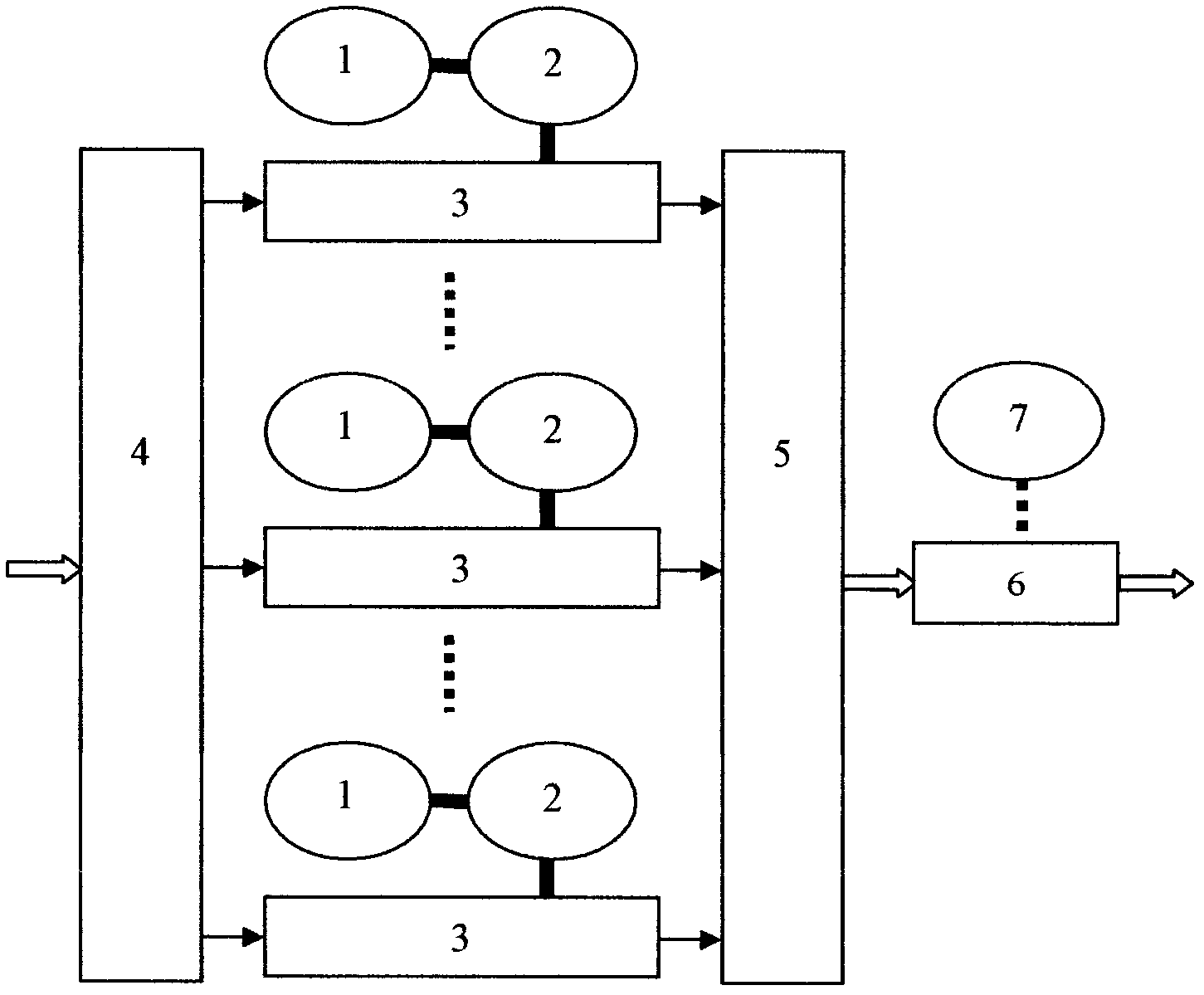

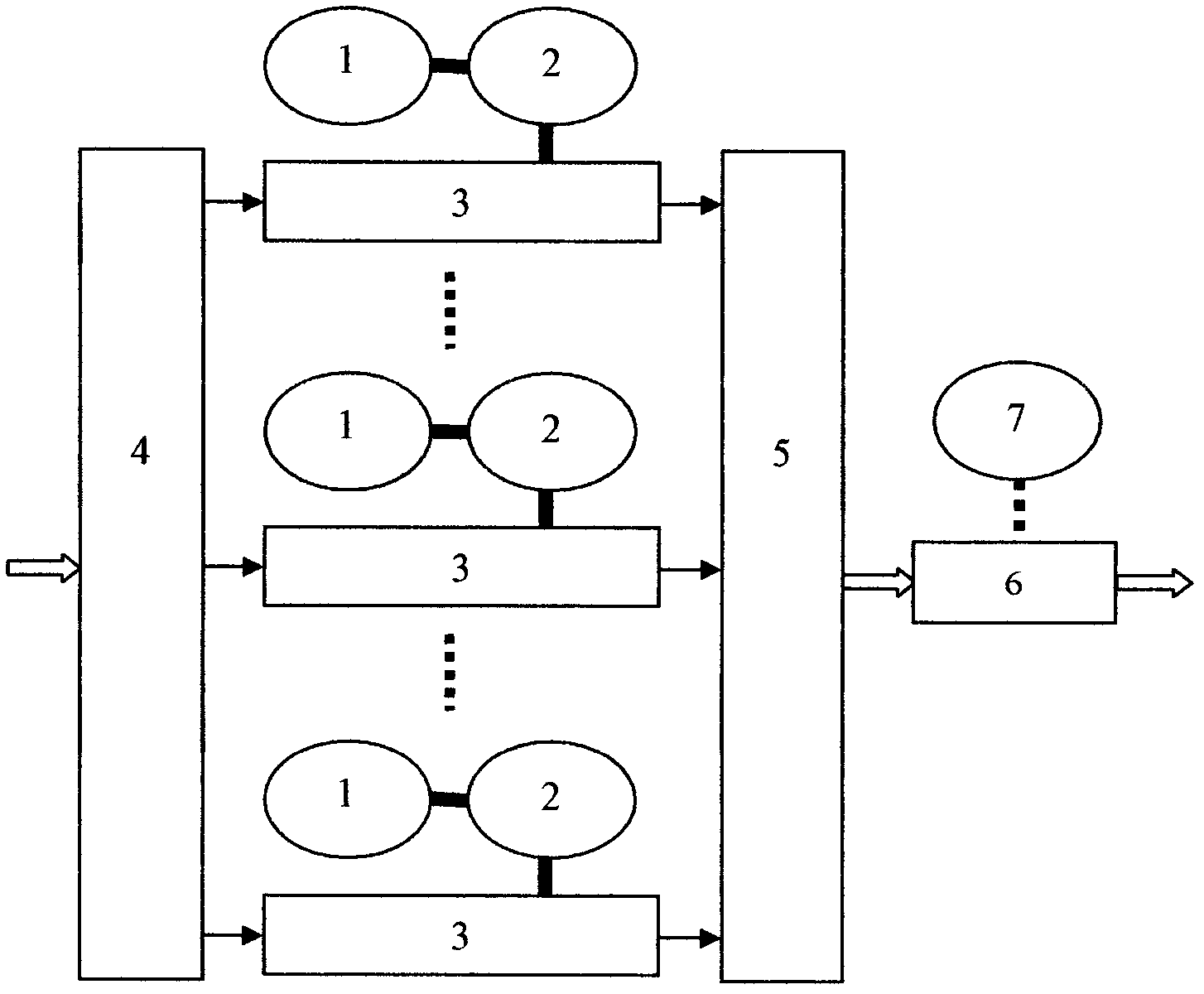

[0029] Such as figure 2 As shown, there are 96 discharge tubes, 96 transformers, and 96 plasma power supplies in this device system. One-to-one correspondence is adopted, that is, each discharge tube is equipped with a power supply and a transformer. The discharge tubes are arranged in row tubes, with an even interval of 150mm between adjacent discharge tubes. Both the inlet air distribution pipe and the outlet air collection pipe have a diameter of 600mm. The device system designed above can work under atmospheric pressure, and can process waste gas of 2800-4800m per hour 3 / h, and is suitable for sulfur-containing, nitrogen-containing odorous gases and benzene series, esters, alcohols, and ethers. The implementation effect shows that when the styrene intake concentration is 1000mg / m 3 , the external voltage of the discharge tube is 9000V, the removal rate of styrene by the device is over 99%, the discharge is stable during the reaction process, and the thermal effect of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com