Power line pull wire making tools

A technology for power lines and tools, which is applied in the field of time-saving and labor-saving tools for 0.4KV-66KV power line pull wires. It can solve the time-consuming and labor-intensive problems of pulling wires, and achieve the effects of flexible use, convenient disassembly and adjustment, and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

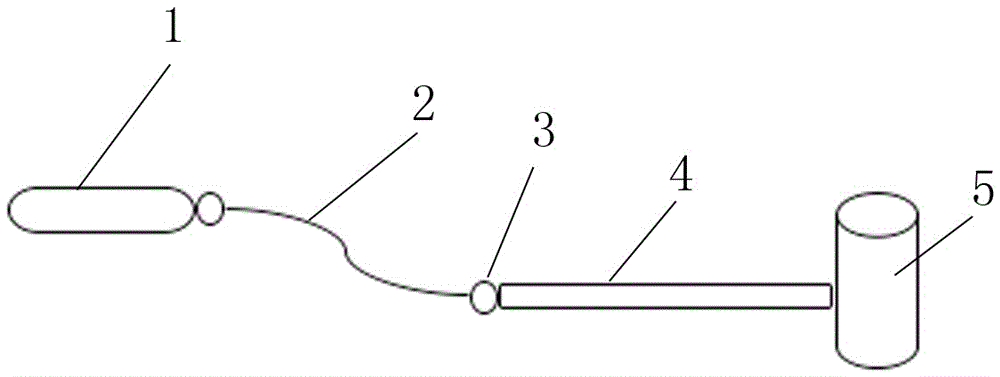

[0017] Such as figure 1 As shown, one end of the hammer handle 4 is connected to the hammer head 5, the other end of the hammer handle 4 is connected to one end of the chain 2 through the movable link 3, and the other end of the chain 2 is connected to the oval collar 1, and the oval collar 1 The width matches the diameter of the pull wire, and the length of the elliptical collar is the sum of the width of the wedge wire spatula and the diameter of the pull wire; the collar is provided with an inner liner, the curvature of the inner liner matches the collar, and the inner liner is connected Adjustment bolt.

[0018] Determined according to the design requirements of the regulations, with 25mm galvanized steel strand 2 As an example, the production process is briefly described as follows. When making the upper end of the pull wire, insert the elliptical collar into the 5mm circle of the galvanized steel strand. and the arc top of the galvanized steel strand, pull the short en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com