Anode aluminium foil after treatment method for aluminium electrolytic capacitor

An aluminum electrolytic capacitor and anode aluminum foil technology, which is applied in capacitor electrodes, capacitor parts, chemical instruments and methods, etc., can solve the problem of shortening the boosting time of the formed foil, unstable riveting of the front and rear rolls, and can not effectively reduce the corrosion of aluminum powder on the surface of the foil. As well as the problems of particles and powder impurities in the holes, it can reduce the instability of riveting, shorten the boosting time and improve the quality of products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Preliminary preparation: first put the aluminum foil into the pretreatment solution and soak it for 120 seconds, wash it with pure water, and then put it into the corrosion A solution once and pass it at 470mA / cm 2 The electric current is treated for 120 seconds, cleaned with pure water and then put into the secondary corrosion B1 liquid to pass through 80mA / cm 2 The electric current is treated for 360 seconds, cleaned with pure water and then put into the secondary corrosion B2 liquid to pass through 80mA / cm 2 The electric current was treated for 360 seconds, and the pre-corrosion foil was obtained by cleaning with pure water. The following post-processing foils are the foils after the above treatments, referred to as pre-corrosion foils.

[0018] Post-treatment: Put the pre-corroded foil into the solution with a temperature of 30°C and a solution containing 5wt% nitric acid, use an ultrasonic frequency of 1KHz, a power of 0.5KW, and ultrasonic treatment for 60 second...

Embodiment 2

[0020] Preparatory conditions are the same as in Example 1.

[0021] Post-treatment: put the pre-corroded foil into a solution containing 4wt% nitric acid at a temperature of 40°C, use an ultrasonic frequency of 11KHz, a power of 1.5KW, and ultrasonic treatment for 45 seconds, take it out, clean it with pure water, and dry it.

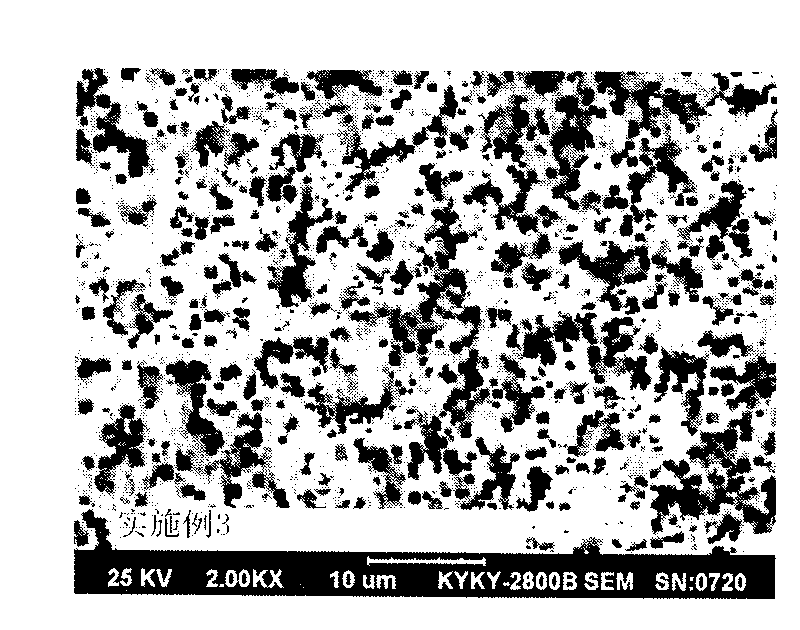

Embodiment 3

[0023] Preparatory conditions are the same as in Example 1.

[0024] Post-treatment: put the pre-corroded foil into a solution containing 4wt% nitric acid at a temperature of 50°C, and use an ultrasonic frequency of 20KHz and a power of 3.0KW for 45 seconds, take it out, clean it with pure water, and dry it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com