Method for treating industrial organic waste gases

An organic waste gas, industrial technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of the adverse effect of the dielectric barrier discharge process, the short gas reaction time, and the failure to make full use of it, and solve the problem of electrode corrosion. effect of the problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Treatment of waste gas experiment

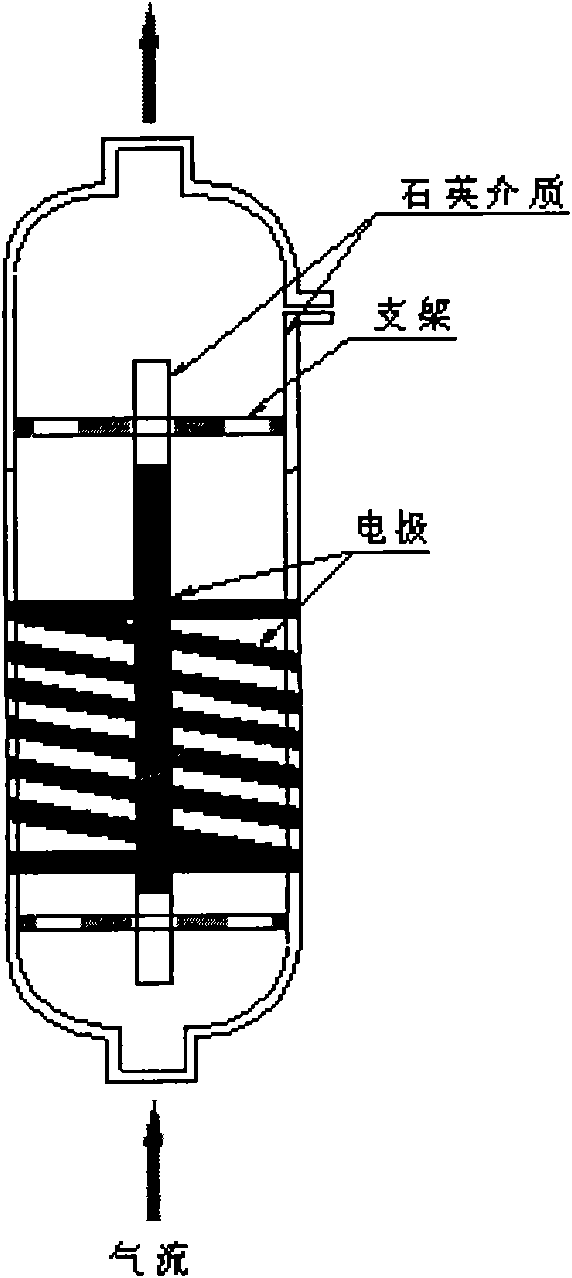

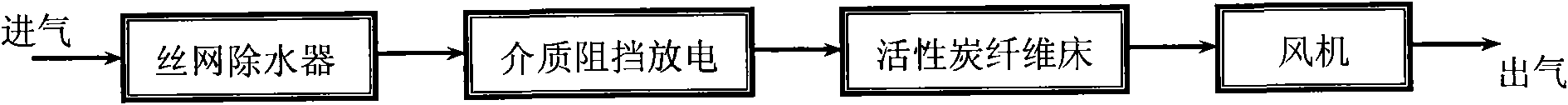

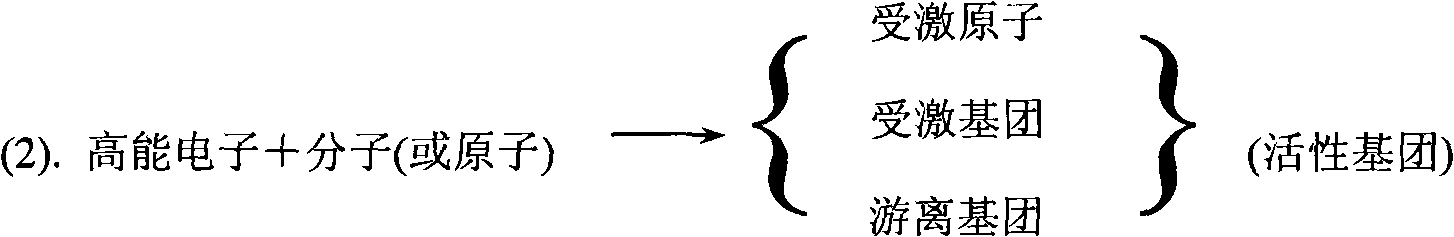

[0034] Take the exhaust gas containing dimethylamine as an example, the gas volume is 4000m 3 / h, concentration 1000mg / m 3 , the gas temperature is between 30°C and 70°C, and the water vapor is supersaturated. After the organic gas containing dimethylamine is collected, it first passes through the screen dehydrator (this unit can be omitted if there is no water vapor) to remove water vapor, and then enters the dielectric barrier discharge plasma reactor, where the bombardment of high-energy electrons is used , make the pollutants undergo a series of reactions, decompose and convert them into carbon dioxide and water or harmless substances, a small amount of undecomposed organic substances, O produced during the reaction process 3 , O and HO · and O 2 When passing through the activated carbon fiber bed, it is adsorbed by the activated carbon fiber and continues to react. Through the adsorption and accumulation of activated carbon f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Wire diameter | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com