Sealing adhesive film for solar cell

A solar cell and sealant film technology, applied in circuits, adhesives, photovoltaic power generation, etc., can solve problems affecting photoelectric conversion efficiency and lower transmittance of EVA film, achieve stable optical performance, ensure photoelectric conversion efficiency, The effect of increasing light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

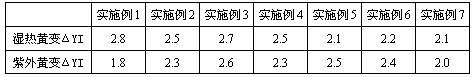

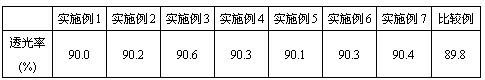

Examples

Embodiment 1

[0060] 3 parts by weight of tert-butyl peroxy-2-ethylhexyl carbonate (Beijing Chiayi Chemical Co., Ltd. TBEC) as the organic peroxide crosslinking agent and 3 parts by weight of trimethylolpropane trimethacrylate ( Sartomer SR350) was added as a crosslinking accelerator to 100 parts by weight of ethylene-vinyl acetate copolymer with a VA content of 26 parts by weight and mixed evenly; then 2 parts by weight of an anti-aging agent (containing 0.8 parts by weight of 2, 2'-Dihydroxy-4-methoxybenzophenone (Eversorb 52 from Taiwan Yongguang Chemical Co., Ltd.) as a UV absorber, 0.6 parts by weight of Lowilite-62 and Lowilite-94 in a weight ratio of 1:1 (Chemtura Corporation ) as a light stabilizer, 0.2 parts by weight of tetrakis[methyl-β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester (IRGANOX-1010 from Ciba Specialty Chemicals) and A mixture of 0.2 parts by weight of tris (2,4-di-tert-butylphenyl) phosphite (Ciba Specialty Chemicals IRGAFOS-168) as an antioxid...

Embodiment 2

[0062] 1 part by weight of tert-butyl peroxy-isopropyl carbonate (Saen Chemical Technology Co., Ltd.) Ma SR350) as a cross-linking accelerator was added to 100 parts by weight of ethylene-vinyl acetate copolymer with a VA content of 28 parts by weight and mixed evenly; then 1 part by weight of anti-aging agent (containing 0.2 parts by weight of 2,2' -Dihydroxy-4-methoxybenzophenone (Eversorb 52 from Taiwan Yongguang Chemical) as a UV absorber, 0.2 parts by weight of a mixture of Lowilite-62 and Lowilite-94 with a weight ratio of 1:1 (Chemtura Company) as Light stabilizer, 0.2 parts by weight of tetrakis [methyl-β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester (IRGANOX-1010 from Ciba Specialty Chemicals) and 0.1 parts by weight A mixture of three (2,4-di-tert-butylphenyl) phosphite (Ciba Specialty Chemicals IRGAFOS-168) as an antioxidant, 0.3 parts by weight of nano-magnesium hydroxide (Yantai Aifer Chemical Technology Co., Ltd.) as an acid absorb...

Embodiment 3

[0064] 0.1 parts by weight of tert-butyl peroxystearyl carbonate (Wuhan Xihua WH-3062) as an organic peroxide crosslinking agent and 0.1 parts by weight of trimethylolpropane trimethacrylate (Sartomer SR350 ) as a cross-linking accelerator was added to 100 parts by weight of ethylene-vinyl acetate copolymer with a VA content of 28 parts by weight and mixed uniformly; then 0.05 parts by weight of an anti-aging agent (containing 0.02 parts by weight of Hydroxy-4-methoxybenzophenone (Eversorb 52 from Taiwan Yongguang Chemical) was used as an ultraviolet light absorber, and 0.01 parts by weight of a mixture of Lowilite-62 and Lowilite-94 with a weight ratio of 1:1 (Chemtura Company) was used as a photostabilizer agent, 0.01 parts by weight of tris(2,4-di-tert-butylphenyl) phosphite (Ciba Specialty Chemical IRGAFOS-168) as an antioxidant, 0.01 parts by weight of nano-magnesium hydroxide (Yantai Aifer Seoul Chemical Technology Co., Ltd.) as an acid absorbent), 1 part by weigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com