Composite conductive agent, preparation method thereof and conductive plastic

A composite conductive agent and conductive plastic technology, applied in the field of conductive polymer materials, can solve problems such as uneven dispersion, easy agglomeration, and unsatisfactory electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

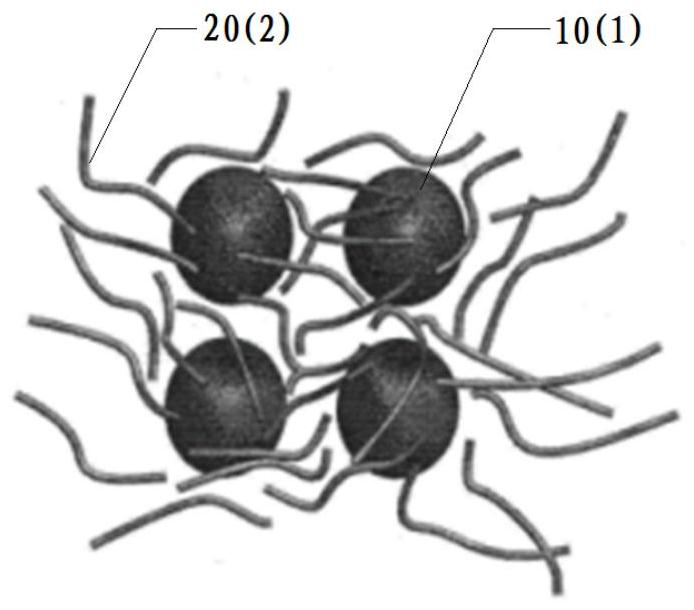

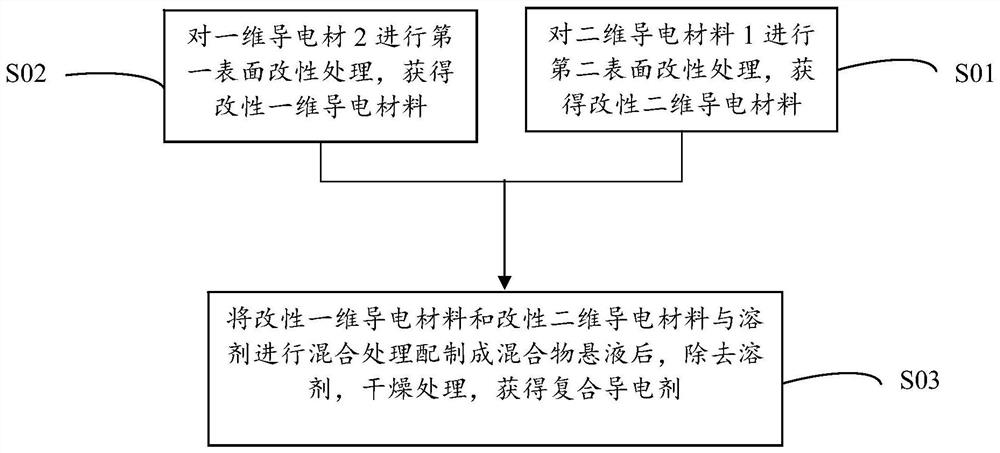

[0039] Correspondingly, based on the above composite conductive agent, the embodiment of the present invention also provides a preparation method of the composite conductive agent. The preparation method technological process of composite conductive agent is as figure 2 shown, combined with figure 1 , including the following steps:

[0040] Step S01: performing a first surface modification treatment on the one-dimensional conductive material 2 to obtain a modified one-dimensional conductive material;

[0041] Step S02: performing a second surface modification treatment on the two-dimensional conductive material 1 to obtain a modified two-dimensional conductive material;

[0042] Step S03: After mixing the modified one-dimensional conductive material and the modified two-dimensional conductive material with a solvent to form a mixture suspension, the solvent is removed and dried to obtain a composite conductive agent.

[0043] Wherein, the first surface modification treatme...

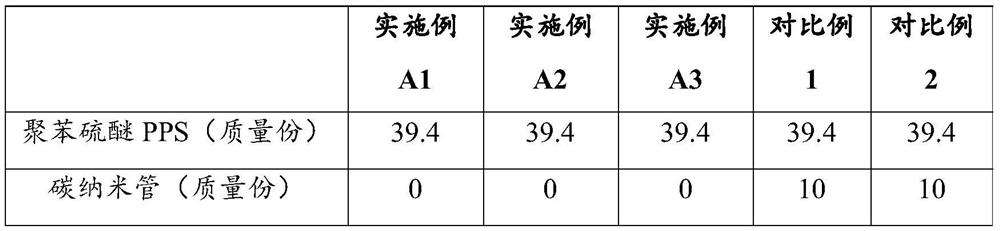

Embodiment A1

[0082] This embodiment provides a composite conductive agent and a preparation method thereof. The composite conductive agent of this embodiment includes graphite and carbon nanotubes distributed and combined on the graphite surface, the carbon nanotubes form carbon nanotubes on the graphite surface, and extend abundant carbon nanotube adhesion fine whiskers, its structure is as follows figure 1 shown. Wherein, the mass ratio of carbon nanotubes to graphite is 1:5.

[0083] The preparation method of composite conductive agent comprises the steps:

[0084] S1: Pour the mixed solution of 1g of multi-walled carbon nanotubes and 200ml of nitric acid and sulfuric acid into a 1:3 mixed acid into a 1000ml beaker for ultrasonic treatment, ultrasonically oscillate at a frequency of 50kHz for 30 minutes, and then wash with deionized water , removing the acid on the surface of the carbon nanotubes until the pH of the washed aqueous solution is 7, and drying it at 80° C. for 24 hours. ...

Embodiment A2

[0088] This embodiment provides a composite conductive agent and a preparation method thereof. The composite conductive agent in this embodiment includes graphite and chopped carbon fiber.

[0089] The preparation method of composite conductive agent comprises the steps:

[0090] S1: Take 1g of chopped carbon fiber and 200ml of nitric acid and sulfuric acid in a 1:3 mixed acid solution and pour it into a 1000ml beaker for ultrasonic treatment. After ultrasonic oscillation at a frequency of 50kHz for 30 minutes, wash with deionized water to remove The acid on the surface of the carbon fiber is chopped until the pH of the washed aqueous solution is 7, and it is baked at 80° C. for 24 hours. Then weigh cetyltrimethylammonium bromide (CTAB) of 20 times the mass of chopped carbon fiber and add it to the pretreated chopped carbon fiber and 300ml of deionized water, and ultrasonically treat it for 5 minutes to prepare positively charged short carbon fiber. cut carbon fiber;

[009...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com