Polymer crosslinked binder, preparation method and application thereof

A binder and polymer technology, which is applied in the field of lithium-ion battery anode materials, can solve problems such as complex preparation process, environmental pollution, and poor mechanical properties, and achieve the effects of simple operation, improved mechanical properties, and reduced liquid absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

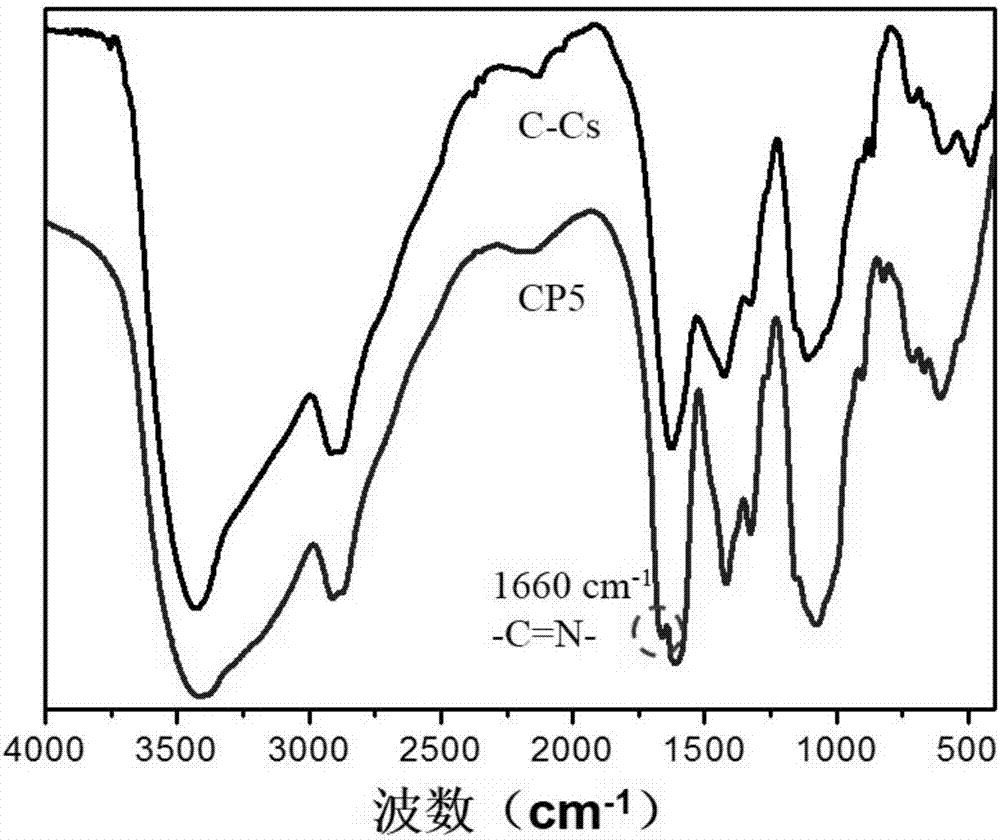

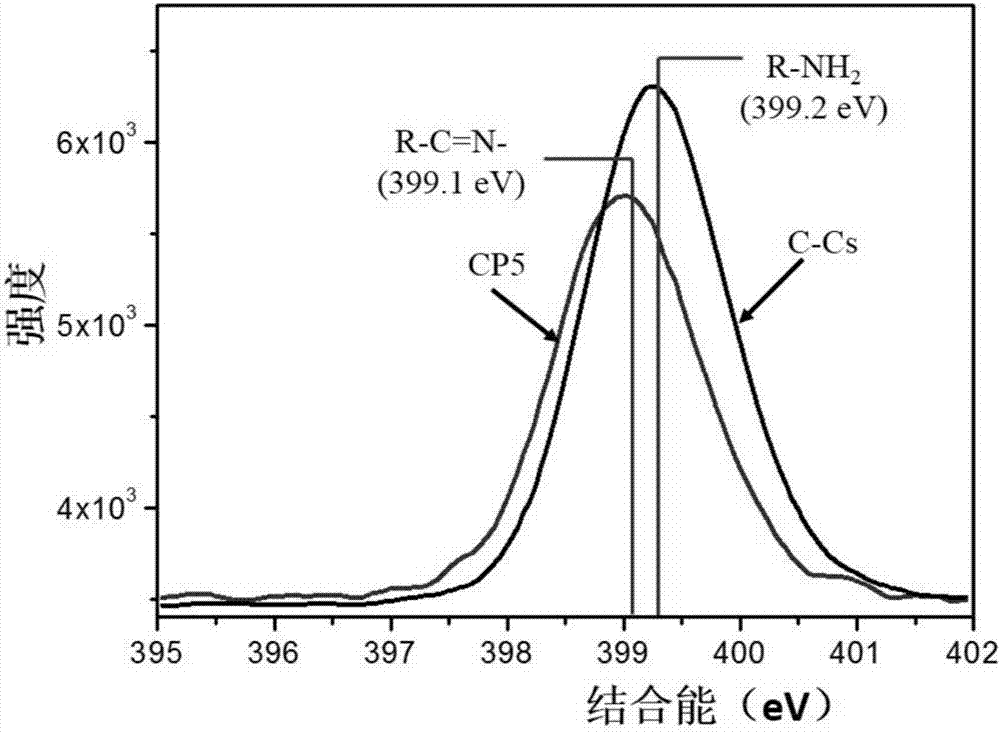

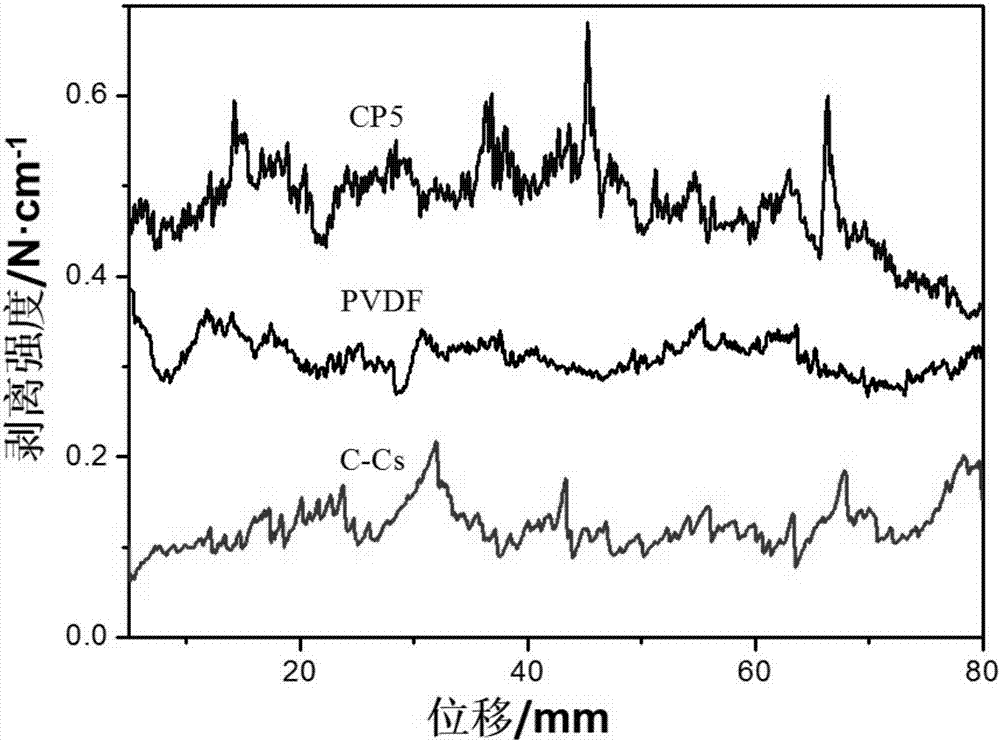

[0066] The present embodiment provides a kind of binder of polyethylene glycol cross-linked carboxymethyl chitosan, and its preparation method comprises the following steps:

[0067] 1) Dissolve 0.15g carboxymethyl chitosan (C-Cs) in deionized water and add a 2% lithium hydroxide solution to adjust the pH value to 9-10, and configure a mass fraction of 1.5% C-Cs Cs alkaline solution.

[0068] 2) Dissolve 0.15g of double-terminal aldehyde-based polyethylene glycol (ALD-PEG-ALD) in deionized water to prepare an aqueous solution of ALD-PEG-ALD with a mass fraction of 1.5%; the number average molecular weight of ALD-PEG-ALD is 2000 .

[0069] 3) Add the prepared ALD-PEG-ALD aqueous solution to the prepared C-Cs alkali solution at a ratio of 5% (accounting for the total mass of the reaction solution), and react at 60-90 degrees Celsius for 2-5 hours.

[0070] 4) The mixed solution obtained in step 3) was ball-milled for 0.5 hours, then placed in a vacuum drying oven, and dried in...

Embodiment 2

[0112] 1) Control the addition of ALD-PEG-ALD to 3% of the total mass of the binder to prepare a modified C-Cs binder and prepare a modified binder solution, which is denoted as CP3.

[0113]2) The CP3 binder solution obtained in step 1) is configured according to the mass ratio of nano-silicon: conductive carbon black: binder = 8:1:1, and the slurry is obtained after being uniformly mixed by ball milling.

[0114] 3) Coat the slurry obtained in step 2 on a copper foil, dry it in vacuum at 60°C for 10 hours, and punch it out to obtain a circular pole piece with a diameter of 14 mm. Control the density of nano-silicon particles on the copper foil to 0.5-0.7 mg·cm by controlling the height of the coating blade -2 .

[0115] 4) Vacuum-dry the circular pole piece obtained in step 3 at 80 degrees Celsius for 10 hours to obtain the required silicon negative pole piece.

[0116] The bonding performance characterization of the binder, the battery assembly technology and the battery ...

Embodiment 3

[0121] 1) Control the addition of ALD-PEG-ALD to 7% of the total mass of the binder to prepare a modified C-Cs binder and obtain a modified binder solution, denoted as CP7.

[0122] 2) The CP7 binder solution obtained in step 1) is configured according to the mass ratio of nano-silicon: conductive carbon black: binder = 8:1:1, and the slurry is obtained after being uniformly mixed by ball milling.

[0123] 3) Coat the slurry obtained in step 2 on a copper foil, dry it in vacuum at 60°C for 10 hours, and punch it out to obtain a circular pole piece with a diameter of 14 mm. Control the density of nano-silicon particles on the copper foil to 0.5-0.7 mg·cm by controlling the height of the coating blade -2 .

[0124] 4) Vacuum-dry the circular pole piece obtained in step 3 at 80 degrees Celsius for 10 hours to obtain the required silicon negative pole piece.

[0125] It can be seen that the difference between CP3, CP5, and CP7 lies in the percentages of the crosslinking agent in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Inverse capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com