Lithium ion battery

A lithium-ion battery, lithium-ion technology, applied in secondary batteries, non-aqueous electrolyte battery electrodes, circuits, etc., can solve problems such as cathode capacity loss, and achieve the effects of increasing capacity, easy operation, and increasing energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

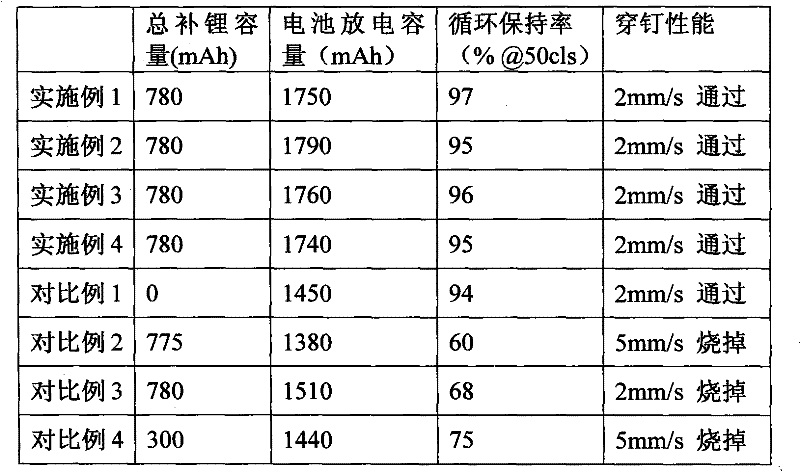

Examples

Embodiment 1

[0026] A lithium-ion battery, comprising a cathode, an anode, a separator between the cathode and anode, and an electrolyte thereof, and the cathode and the separator are laminated to prepare an electric core 363173 (length is 73mm, width is 31mm, thickness is 3.6mm ). The anode is a silicon-based anode, and 9um copper foil is used as a current collector. The formula of the slurry is: Si active material: SP: CMC: SBR = 90:2:4:4. The cathode formula is: lithium cobaltate:SP:PDVF=97:1.6:1.4.

[0027] The active material of the lithium-replenishing cathode is lithium cobaltate. The size of the lithium-replenishing cathode is 69mm long and 30mm wide, and it is placed close to the side of the battery cell. The lithium-supplementing cathode is arranged within a distance of 30 mm from the side of the battery cell, which is less than the width of the lithium-supplementing cathode.

[0028] The lithium-supplementing cathode performs lithium supplementation on the cathode and anode re...

Embodiment 2

[0034]The same cell as in Example 1. The active material of the lithium-replenishing cathode is lithium nickel manganese cobalt oxide, and the size of the lithium-replenishing cathode is 69 mm in length and 20 mm in width, and is placed close to the side of the cell. The lithium-replenishing cathode is arranged within a distance of 20 mm from the side of the cell, which is less than the width of the lithium-replenishing cathode.

[0035] Lithium-supplementing cathodes perform two lithium-supplementing operations on cathodes and anodes, respectively. For the first time, after the cell is activated and at 50% state of charge (SOC), the cathode is first supplemented with lithium, and the amount of lithium supplement is 1 / 3 of the total amount of lithium ions on the cathode, and then the anode is supplemented with lithium. , the amount of lithium replenishment is 1 / 6; after the first cycle of lithium replenishment is completed, the second lithium replenishment is performed, and t...

Embodiment 3

[0041] The same cell as in Example 1. The active material of the lithium-replenishing cathode is lithium manganate, and the size of the lithium-replenishing cathode is 69 mm in length and 10 mm in width, and it is placed close to the side of the battery cell. is smaller than the width of the lithium-supplemented cathode.

[0042] Lithium-supplementing cathodes perform two lithium-supplementing operations on cathodes and anodes, respectively. For the first time, after the cell is activated and at 50% state of charge (SOC), the cathode is first supplemented with lithium, and the amount of lithium supplement is 1 / 3 of the total amount of lithium ions on the cathode, and then the anode is supplemented with lithium. , the amount of lithium replenishment is 1 / 6; after the first cycle of lithium replenishment is completed, the second lithium replenishment is performed, and the cathode and anode are successively replenished with 1 / 3 and 1 / 6 of the capacity. The used lithium replenis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com