Silicon anode material and preparation method thereof and lithium battery using silicon anode material

A negative electrode material, lithium ion battery technology, applied in battery electrodes, secondary batteries, electrode manufacturing, etc., can solve the problem of inability to mass-produce cyclic performance silicon negative electrode materials, improve the problem of pulverization and shedding, high specific capacity, and improved The effect of cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] A method for preparing the above negative electrode material, comprising: sintering pretreated silicon dioxide powder and carbon reducing agent powder at high temperature in vacuum; taking the total weight of silicon dioxide and carbon reducing agent as a basis, the carbon reducing agent The weight accounts for 16.67%-35.8%.

[0021] The raw material for the preparation of silica refers to natural quartz sand with a purity of more than 99%, which may contain Al 3 o 2 , CaO, Fe 2 o 3 and P 2 o 5 and other impurities.

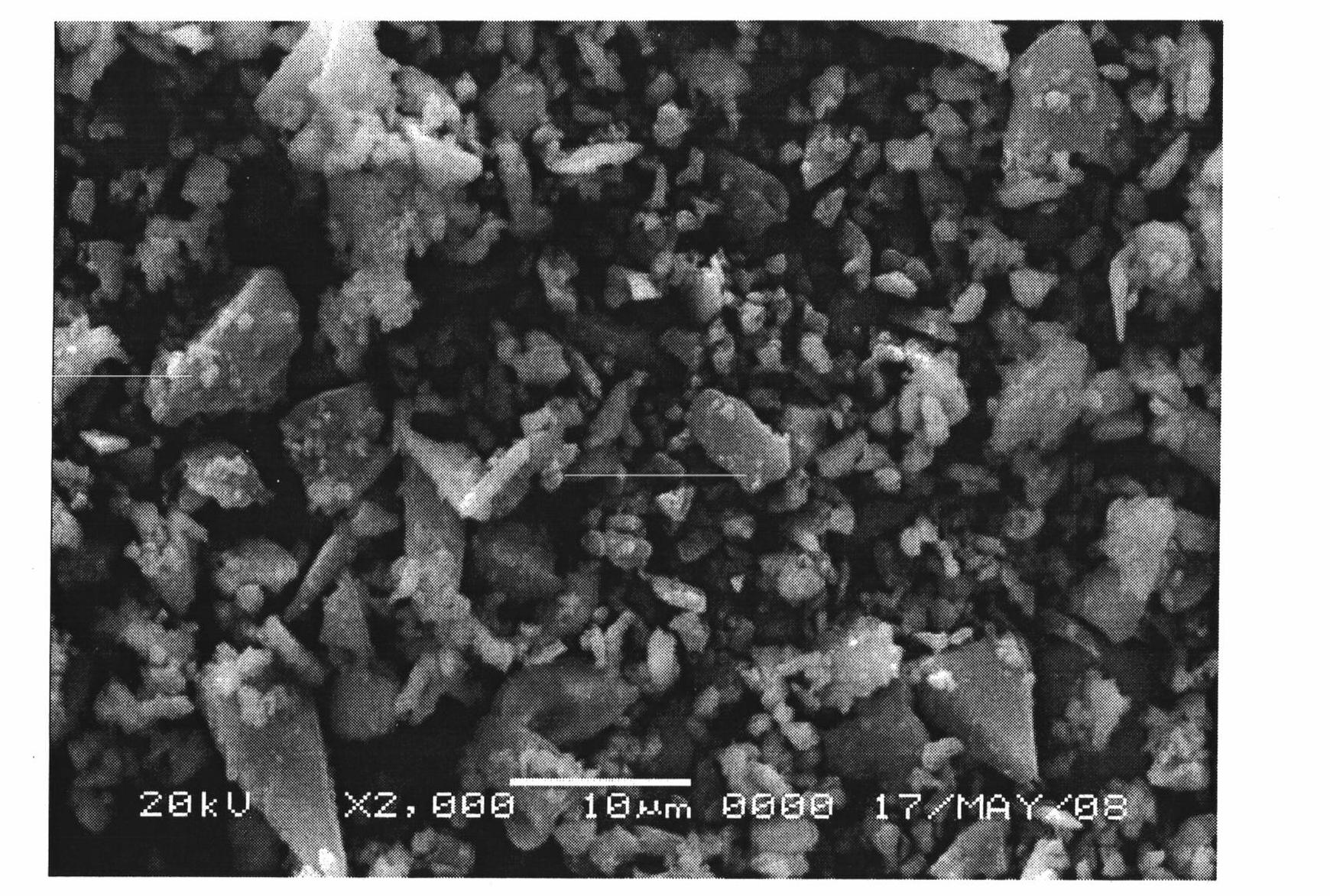

[0022] The pretreatment refers to pulverizing and grinding the silicon dioxide into ultrafine silicon dioxide with a particle size of 5-20 μm, and then chemically pickling and drying the ultrafine silicon dioxide.

[0023] The crushing and grinding is mechanical high-energy ball milling under a protective gas atmosphere, wherein the protective gas is an inert gas.

[0024] Described chemical pickling can be well-known to those skilled in the art, al...

Embodiment 1

[0044] The quartz sand with a purity of more than 99% is mechanically milled to 10 μm by a high-energy ball in an argon atmosphere to obtain ultrafine silica powder.

[0045] Then put the superfine silicon dioxide powder into aqua regia and stir for 3 hours, and then rinse repeatedly with pure water after filtering; then put it into hydrofluoric acid with a mass percentage concentration of 0.96wt% and stir for 3 hours, and then rinse repeatedly with pure water after filtering; Put it into a centrifuge for dehydration, and dry it in an oven at 100°C for 5 hours to make the water content <1%. Made into pretreated silica powder.

[0046] Coke powder with an average particle size of <50 μm is mechanically milled with high-energy balls in an argon atmosphere, crushed and classified to prepare a carbon reducing agent with a particle size of 0.5 μm.

[0047] Mix 360 grams of pretreated silica powder and 120 grams of carbon reducing agent, and stir thoroughly for 12 hours to make the...

Embodiment 2

[0051] The difference from Example 1 is that 420 grams of pretreated silica powder and 120 grams of carbon reducing agent were mixed. Negative electrode material A2 was prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com