Method of improving performance of lithium ion battery silicon anode material

A lithium-ion battery and material performance technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of poor conductivity, low first charge and discharge efficiency, etc., and achieve the effect of improving other performances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

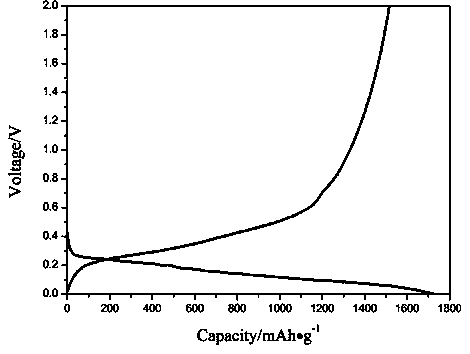

Image

Examples

Embodiment 1

[0035] A method for improving the performance of a lithium-ion battery silicon negative electrode material, comprising the following steps:

[0036] (1) Negative electrode preparation of silicon oxide composite material:

[0037] 1) Weigh a certain amount of SiO powder, pour it into deionized water whose mass is 10 times that of SiO, and then add a certain amount of graphite and glucose; specifically, weigh 45g of SiO powder, pour it into 450g of In water ethanol, then add 4.5g of graphite and 4.5 of glucose. Also, the particle size of the SiO powder is 10 μm.

[0038] 2) Put the mixed solution into a high-energy ball mill for ball milling, the ball milling time is 5 hours, and the rotation speed is 900r / m.

[0039] 3) Put the ball-milled precursor material into a tube furnace, heat it to 800°C in an argon atmosphere, keep it warm for 5 hours, and then cool it down to room temperature naturally; specifically, dry the ball-milled precursor material and pour it into Crucible,...

Embodiment 2

[0047] A method for improving the performance of a lithium-ion battery silicon negative electrode material, comprising the following steps:

[0048] (1) Negative electrode preparation of silicon oxide composite material:

[0049] 1) Weigh a certain amount of SiO powder, pour it into deionized water whose mass is 10 times that of SiO, and then add a certain amount of graphite and glucose; specifically, weigh 50g of SiO powder, pour it into 500g of In water ethanol, then add the glucose of 5g graphite and 5g. Also, the particle diameter of the SiO powder is 10 μm.

[0050] 2) Put the mixed solution into a high-energy ball mill for ball milling, the ball milling time is 6 hours, and the rotation speed is 800r / m.

[0051] 3) Put the ball-milled precursor material into a tube furnace, heat it to 1000°C in an argon atmosphere, keep it warm for 4 hours, and then cool it down to room temperature naturally; specifically, dry the ball-milled precursor material and pour it into Crucib...

Embodiment 3

[0058] A method for improving the performance of a lithium-ion battery silicon negative electrode material, comprising the following steps:

[0059] (1) Negative electrode preparation of silicon oxide composite material:

[0060] 1) Weigh a certain amount of SiO powder, pour it into deionized water whose mass is 10 times that of SiO, and then add a certain amount of graphite and glucose; specifically, weigh 55g of SiO powder, pour it into 550g of In water ethanol, then add the glucose of 5.5g graphite and 5.5g. Also, the particle diameter of the SiO powder is 10 μm.

[0061] 2) Put the mixed solution into a high-energy ball mill for ball milling, the ball milling time is 7 hours, and the rotation speed is 950r / m.

[0062] 3) Put the ball-milled precursor material into a tube furnace, heat it to 850°C in an argon atmosphere, keep it warm for 6 hours, and then cool it down to room temperature naturally; specifically, dry the ball-milled precursor material and pour it into Cru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com