High-temperature-resistant glaze

A technology of high temperature resistance and glaze, which is applied in the field of ceramic glaze, can solve the problems of poor thermal stability, destruction of molecular structure, large thermal expansion coefficient, etc., and achieve the effect of maintaining smooth surface, enhancing thermal stability and reducing shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

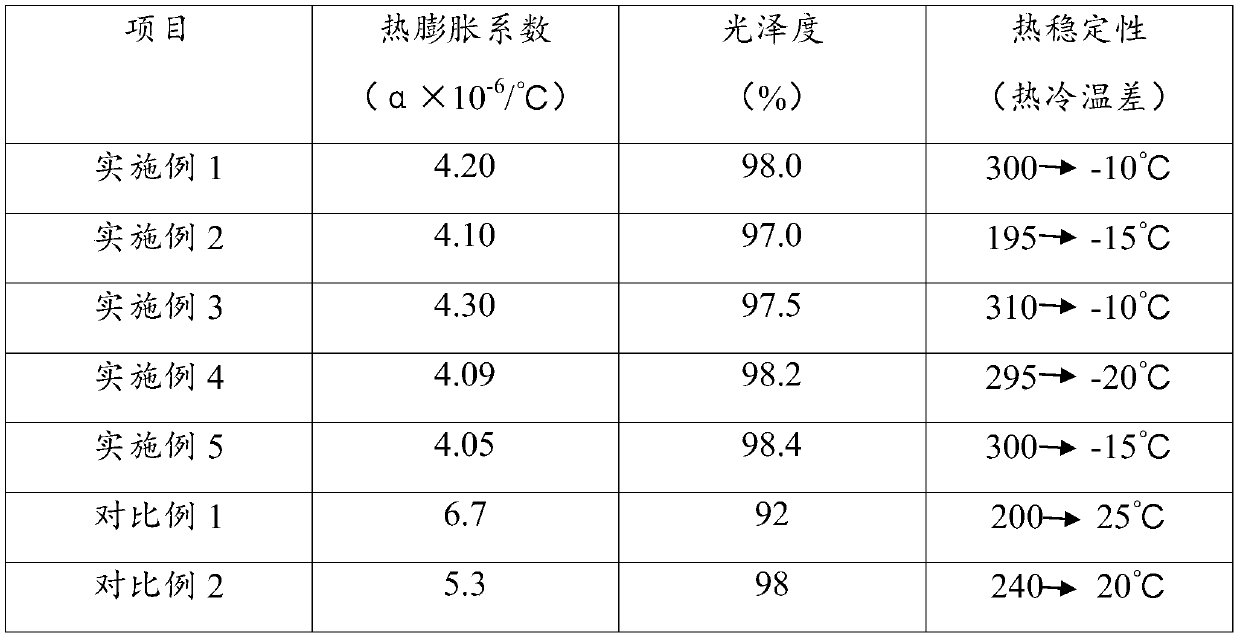

Examples

Embodiment 1

[0015] A high-temperature-resistant glaze, the specific mass parts of the raw materials of the glaze include: 8 parts of silicon dioxide, 5 parts of nanometer yttrium oxide, 3 parts of modified glass fiber, 10 parts of polyethylene glycol, 30 parts of 325 mesh kaolin 1 part, 1 part of lithium oxide, 3 parts of sodium carboxymethyl cellulose and 4 parts of nano neodymium oxide.

Embodiment 2

[0017] A high-temperature-resistant glaze, the specific mass parts of each raw material of the glaze includes: 12 parts of silicon dioxide, 15 parts of nanometer yttrium oxide, 8 parts of modified glass fiber, 18 parts of polyethylene glycol stearate, 45 parts of 800 mesh kaolin, 7 parts of lithium oxide, 14 parts of sodium carboxymethyl cellulose and 9 parts of nano-neodymium oxide.

Embodiment 3

[0019] A high temperature resistant glaze, the specific mass parts of the raw materials of the glaze include: 10 parts of silicon dioxide, 13 parts of nanometer yttrium oxide, 5 parts of modified glass fiber, 15 parts of polyoxyethanol, 41 parts of 550 mesh kaolin , 4 parts of lithium oxide, 9 parts of sodium carboxymethyl cellulose and 6 parts of nano neodymium oxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com