High-performance asphalt composition and preparation method thereof

A kind of asphalt composition, high-performance technology, applied in the direction of building structure, building components, building insulation materials, etc., can solve the problems of asphalt pavement easy to become hard and brittle, less polyimide addition, freeze-thaw loose, etc., to achieve Effects of improving thermal and chemical stability, high temperature resistance and stability, and improving elastic recovery ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

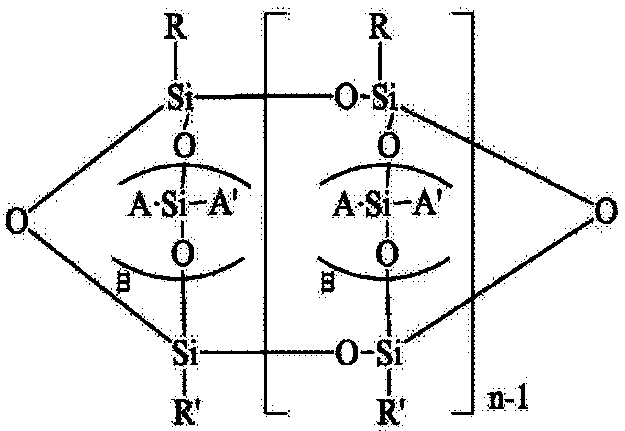

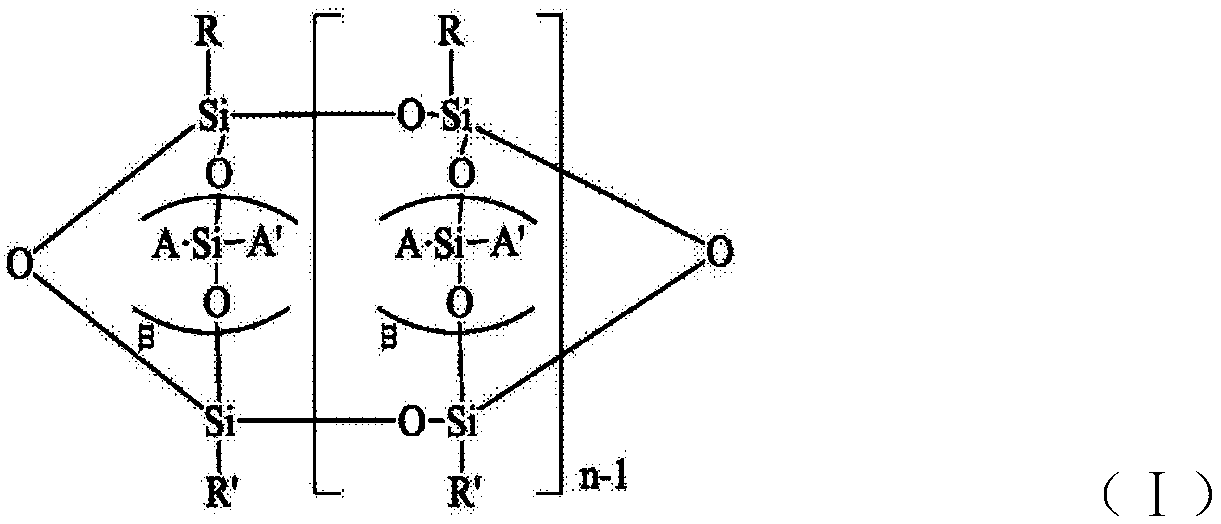

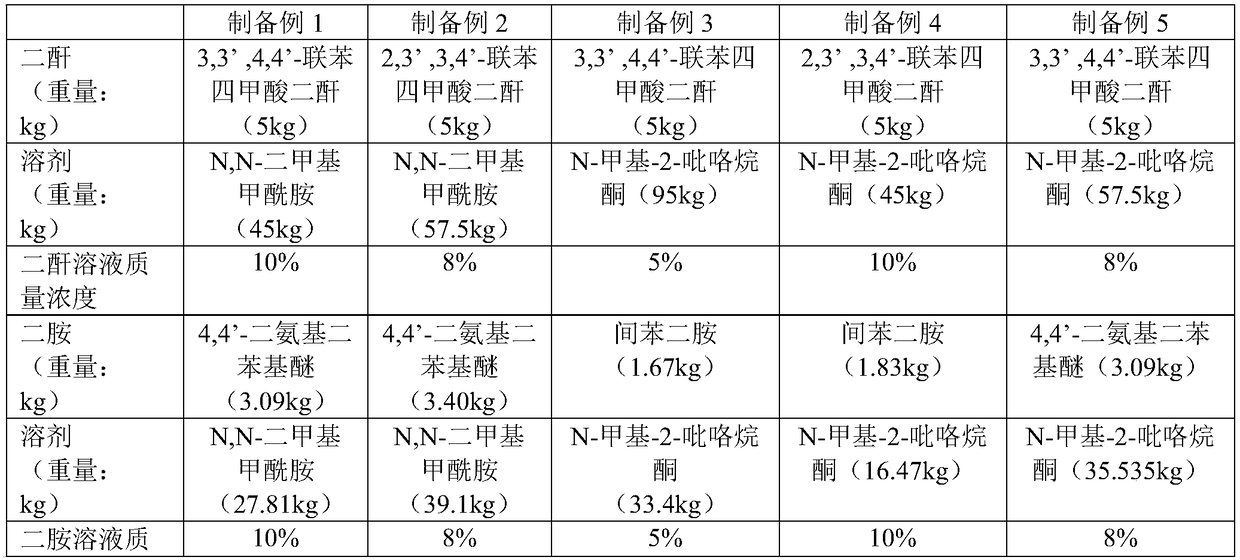

[0033] The self-terminated trapezoidal polysiloxane-modified polyimide powder was prepared according to the following steps (1)-(4), wherein the raw materials, proportions, and reaction conditions are shown in Table 1.

[0034] (1) Dissolve the dianhydride in the solvent to prepare a dianhydride solution with a mass concentration of 5-10%, and add dropwise a diamine solution of the same solvent with a mass concentration of 5-10% to the solution, where the dianhydride and the two The molar ratio of amine is 1.0-1.1:1 to obtain a polyamic acid solution;

[0035] (2) Add 0.1 to 5% of the mass of the polyamic acid solution of the amino-containing ladder-shaped organosiloxane to make the reaction fully;

[0036] (3) The product of step (2) is prepared into a 5-80 μm thick amino-containing ladder-shaped organosiloxane modified polyimide film by solution casting, salivation, or solution extrusion;

[0037] (4) Cut the film to powder with 400-500 mesh. Among them, the self-blocking ladder-sh...

Embodiment

[0043] The products Z-1 to Z-5 in the above production examples are used as polyimide powder raw materials to prepare a pitch composition. The components and ratios are shown in Table 2 below.

[0044] (1) Mix auxiliaries, enhancers, and mineral materials uniformly before use;

[0045] (2) Heat the petroleum pitch to 125°C (or 120°C, 130°C), add the polyimide powder and the mixture of step (1), and stir for 5-10 minutes;

[0046] (3) Cool down to 65°C (or 60°C, 70°C), add tackifier, elastomer and stir again to evenly cool down to 50°C (or 45°C, 55°C) before construction.

[0047] Table 2

[0048]

[0049] Among them, in Table 2, "A" represents a mixture of limestone powder and quartz sand powder with a mass ratio of 1:1; "B" represents a mixture of limestone powder and quartz sand powder with a mass ratio of 2:1; "C" represents limestone A mixture of powder and fly ash powder with a mass ratio of 3:1; "D" represents a mixture of limestone powder and fly ash powder with a mass ratio of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com