Surface modification method and application of silicon dioxide

A surface modification and silicon dioxide technology, applied in the field of chemical engineering, can solve problems such as the decrease of elastic modulus, the increase of the viscosity of packaging materials, and the increase of thermal expansion coefficient, so as to reduce the thermal expansion coefficient and viscosity, increase the elastic modulus, and aromatic The effect of high ring rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] In the present embodiment, the modification process of silica is as follows:

[0048] 1) Preheat 1 kg of silica powder with an average particle size of 500 nanometers at 180°C for 3 hours in vacuum;

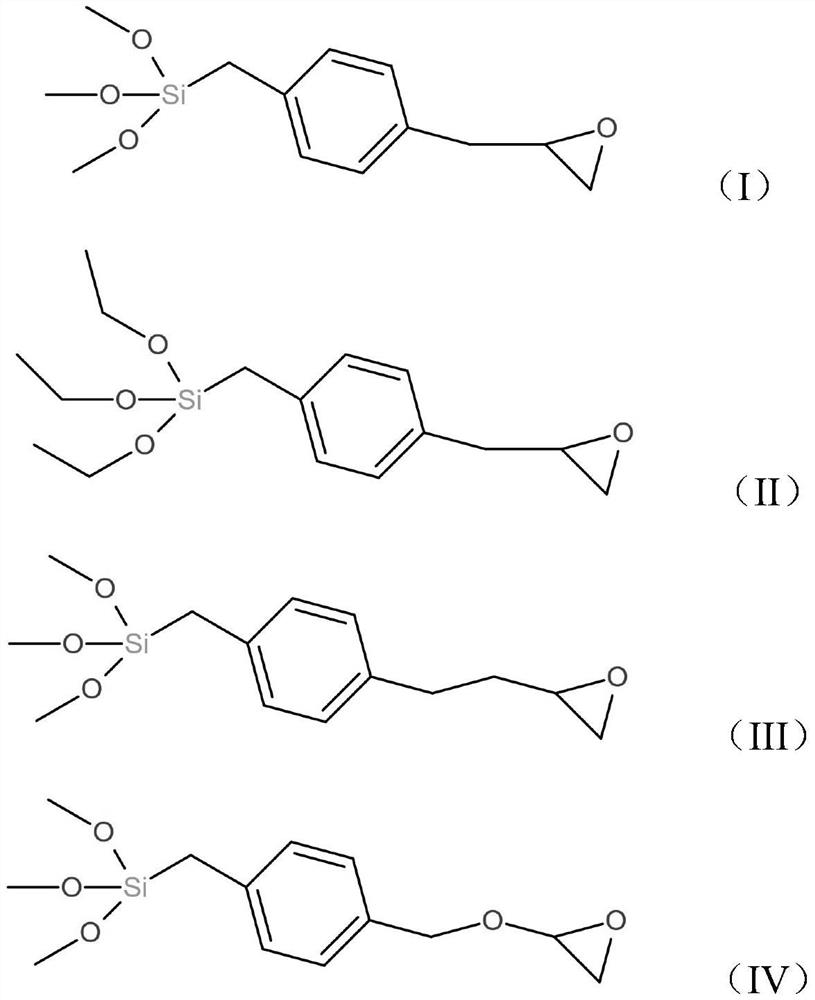

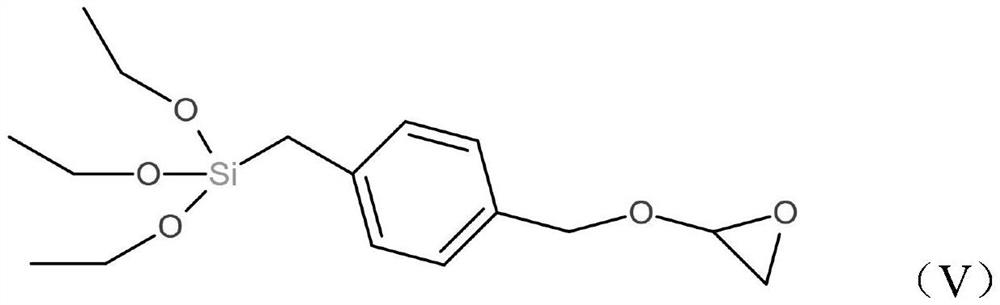

[0049] 2) Spray 20g of trimethoxy ({[4-(epoxy-2-yl)phenyl]methyl})silane on the silica powder in the form of a spray at room temperature;

[0050] 3) Stir at 115° C. at a high speed of 600 rpm for 60 minutes to obtain epoxy-modified silicon dioxide micropowder.

[0051] Effect test:

[0052] ①Add the above-mentioned epoxy-modified silica powder into the bisphenol A epoxy resin, the mass ratio is 5:3, mix evenly and defoam in the mixer at 2000 rpm and vacuum condition, use Rheometer test room temperature viscosity (shear rate 50 / second);

[0053] ②Add the above-mentioned epoxy-modified silica powder to bisphenol A epoxy resin containing curing agent, the mass ratio of epoxy-modified silica powder to bisphenol A epoxy resin is 5:3, The quality of the curing agent is 25% ...

Embodiment 2

[0055] In the present embodiment, the modification process of silica is as follows:

[0056] 1) Preheat 1 kg of silica powder with an average particle size of 500 nanometers at 180°C for 3 hours in vacuum;

[0057] 2) Spray 20g of ({4-[2-(oxirane-2-yl)ethyl]phenyl}methyl)silane on the silica powder in the form of a spray at room temperature;

[0058] 3) Stir at 115° C. at a high speed of 600 rpm for 60 minutes to obtain epoxy-modified silicon dioxide micropowder.

[0059] Effect test:

[0060] ①Mix the above-mentioned epoxy-modified silica powder and bisphenol A epoxy resin according to the mass ratio of 5:3, mix them evenly in a mixer at 2000 rpm and vacuum conditions, and defoam them, and test them with a rheometer Viscosity at room temperature (shear rate 50 / sec);

[0061] ②Add the above-mentioned epoxy-modified silica powder to bisphenol A epoxy resin containing curing agent, the mass ratio of epoxy-modified silica powder to bisphenol A epoxy resin is 5:3, The quality of...

Embodiment 3

[0063] In the present embodiment, the modification process of silicon dioxide is as follows:

[0064] 1) Preheat 1 kg of silica powder with an average particle size of 500 nanometers at 180°C for 3 hours in vacuum;

[0065] 2) Spray 20g of trimethoxy ({4-[(epoxy-2-oxyl)methyl]phenyl}methyl)silane on the silica powder in the form of a spray at room temperature;

[0066] 3) Stir at 115° C. at a high speed of 600 rpm for 60 minutes to obtain epoxy-modified silicon dioxide micropowder.

[0067] Effect test:

[0068] ①Mix the above-mentioned epoxy-modified silica powder and bisphenol A epoxy resin according to the mass ratio of 5:3, mix them evenly in a mixer at 2000 rpm and vacuum conditions, and defoam them, and test them with a rheometer Viscosity at room temperature (shear rate 50 / sec);

[0069] ②Add the above-mentioned epoxy-modified silica powder to bisphenol A epoxy resin containing curing agent, the mass ratio of epoxy-modified silica powder to bisphenol A epoxy resin is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com