Preparation method of low-cost glass ceramic

A glass-ceramic, low-cost technology, applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve the problems of affecting the structural stability of crystal glass, increasing the viscosity of glass liquid at high temperature, and difficult operation of water quenching process, etc. Achieve the effects of increasing economic added value, enhancing solubility performance, and improving nucleation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

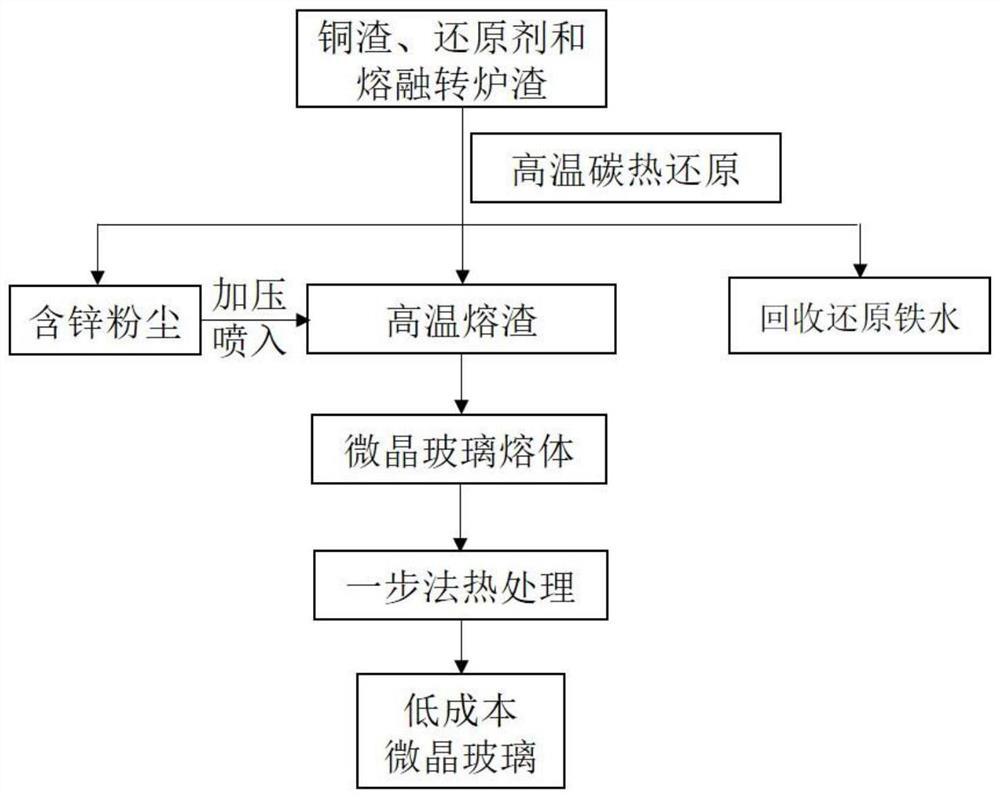

[0031] A method for preparing low-cost glass-ceramics, which uses high-temperature smelting reduction tailings and zinc-containing dust produced in the process of reducing and recovering iron after adding copper slag to high-temperature molten converter slag as low-cost glass-ceramic base materials. Low-cost glass-ceramic is produced after heat treatment process. The preparation process of low-cost glass-ceramics can be set near the high-temperature converter furnace, and the high-temperature molten converter slag after slag extraction can be directly added as raw materials to the copper slag reduction and recovery process. In this way, not only can the high-efficiency utilization of converter slag slag and high-temperature smelting reduction tailings waste heat be achieved, low-cost reuse of high-temperature slag heat can be achieved, but also copper slag and iron in converter slag can be recovered at the same time.

[0032] Among them, SiO in copper slag 2 The mass fraction...

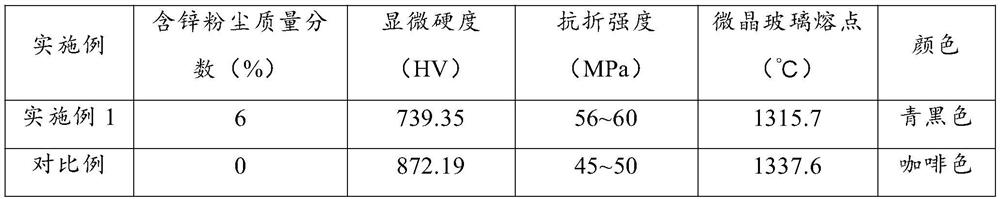

Embodiment 1

[0041] see figure 1 As shown, the present embodiment provides a method for preparing low-cost glass-ceramic, comprising the following steps:

[0042] S1. According to the mass ratio of copper slag, industrial grade alumina and coke as 1:0.07:0.12, mix the samples evenly and grind them until the particle size is less than 0.074mm to obtain a mixture. Pour the mixture directly into the high-temperature molten converter slag and heat up to 1500°C and hold for 1 hour to obtain reduced iron, high-temperature melting reduction tailings and zinc-containing dust; the mass ratio of copper slag to high-temperature melting converter slag is 1:0.4;

[0043] S2. Spray the zinc-containing dust generated during the copper slag reduction and recovery process into the high-temperature slag under high pressure to obtain a basic glass melt; the mass fraction of the zinc-containing dust in the low-cost glass-ceramic base material is 6 wt %;

[0044] S3. Pouring the low-cost glass-ceramic melt ob...

Embodiment 2-3

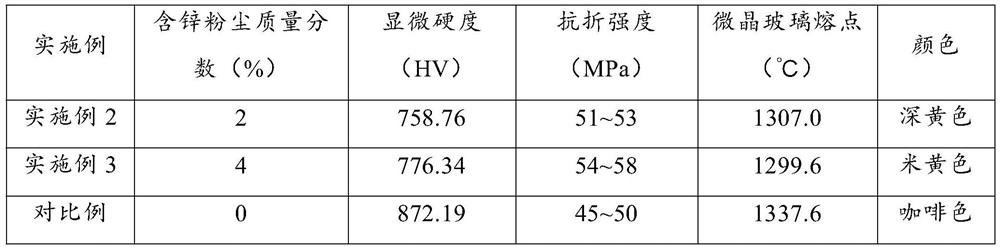

[0052] Embodiment 2-3 provides a method for preparing a low-cost glass-ceramic. Compared with Example 1, the difference is that the mass fraction of zinc-containing dust added during the preparation of glass-ceramics in Example 2-3 is 2wt. %, 4wt%, and the rest are roughly the same as in Example 1, and will not be repeated here.

[0053] Performance tests were performed on the low-cost glass-ceramics prepared in Examples 2-3, and the test results are shown in the table below.

[0054] Table 2 Example 2-3 and the performance test results of glass-ceramics prepared by comparative examples

[0055]

[0056] It can be seen from Table 2 that the glass-ceramic colors in Examples 2 and 3 are dark yellow and beige respectively, and the glass-ceramic in the comparative example is brown, indicating that different additions of zinc-containing dust can change the color of the glass-ceramic. The microhardness of the glass-ceramics prepared after adding zinc-containing dust in Examples ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com