Honeycomb ceramic support and preparation method thereof

A honeycomb ceramic carrier and powder technology, used in ceramic products, catalyst carriers, chemical instruments and methods, etc., can solve the problems of high toxicity and secondary pollution of materials, improve thermal shock resistance, prolong service life, The effect of improving catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

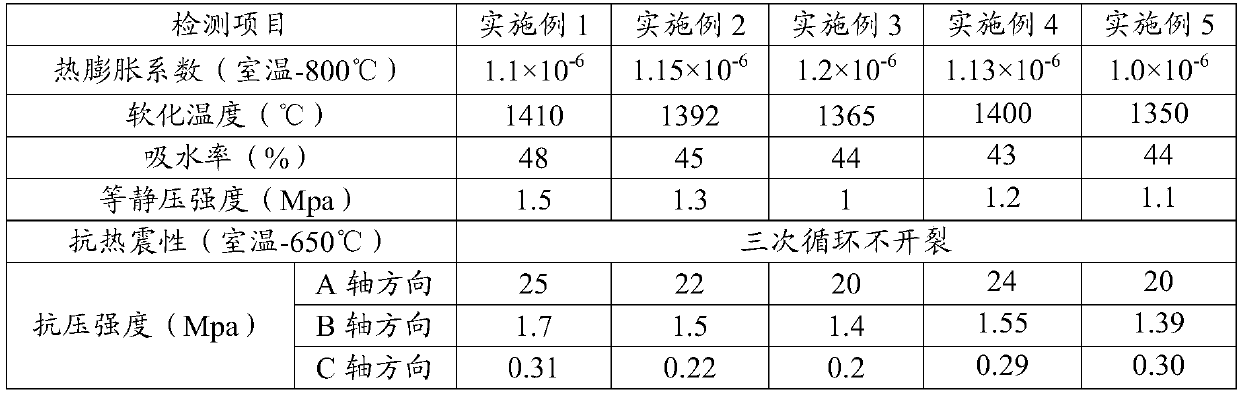

Examples

preparation example Construction

[0061] In the preparation method of the illite powder, the natural illite mineral is used as a raw material, and the powder is firstly processed through crushing and grinding. Preferably, the particle size distribution D97 of the powder is 40 μm˜500 μm.

[0062] Preferably, the mass percentage of illite in the natural illite mineral is greater than or equal to 20%.

[0063] After obtaining the powder, activate the powder at 300-500°C, preferably at 410-500°C; then, attach a solution containing functional elements to the activated powder On, illite functional powder is obtained. The solution containing functional elements is attached to the surface or inside of the activated powder.

[0064] Preferably, the solution containing functional elements is attached to the activated powder by spraying or spraying. The functional element is one or more selected from Ce, Pt and Pd. The mass of the functional elements is 0.05%-0.1% of the mass of the illite functional powder.

[0065...

Embodiment 1

[0084] Prepare binder: mix water and methyl cellulose at a mass ratio of 97:3 to obtain a binder. Use after 24 hours.

[0085] Making green body: weigh 10 parts of illite functional powder, Al 2 o 3 43 parts, 19 parts of MgO and 22 parts of water are mixed evenly, and the particle size is 5-11 μm. Then add 1 part of sawdust powder, 0.1 part of aluminum stearate, 0.5 part of tung oil, 0.1 part of glycerin, and 1 part of binder, stir evenly, and press it into a cylindrical shape under 100 MPa, wherein the honeycomb hole is 400 holes / square inch, and the wall thickness 0.15mm. The molded body was dried in a microwave oven at 70°C for 40 minutes.

[0086] Firing the green body: the heating rate is controlled at 3-5°C / min, the temperature is raised to 1345-1355°C and kept at 1345-1355°C for 4 hours to obtain a honeycomb ceramic carrier.

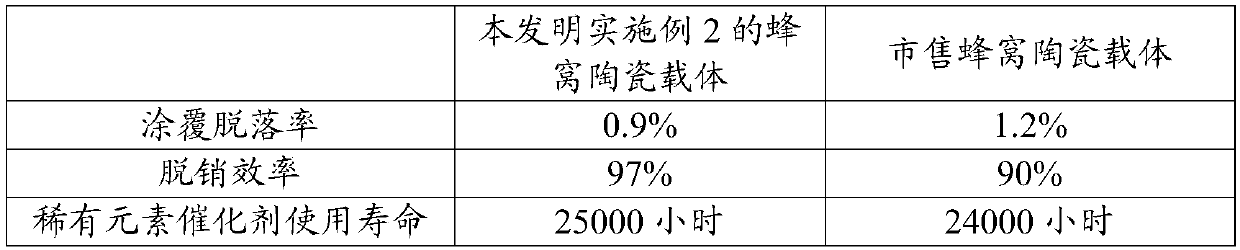

Embodiment 2

[0088] Prepare the binder: mix water and methyl cellulose at a mass ratio of 95:3 to obtain the binder. Use after 24 hours.

[0089] Making green body: weigh 13 parts of illite functional powder, Al 2 o 3 40 parts, 17 parts of MgO and 25 parts of water are mixed evenly, and the particle size is 5-11 μm. Then add 3 parts of wood powder, 0.3 parts of aluminum stearate, 1 part of tung oil, 0.5 parts of glycerin, and 3 parts of binder and stir evenly, and press it into a cylindrical shape under 90 MPa, wherein the honeycomb hole is 400 holes / square inch, and the wall thickness 0.15mm. The molded body was dried in a microwave oven at 80°C for 45 minutes.

[0090] Firing the green body: the heating rate is controlled at 3-5°C / min, the temperature is raised to 1395-1405°C, and the temperature is kept at 1395-1405°C for 3 hours to obtain a honeycomb ceramic carrier.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com