Multiple carbon and ceramic base composite material piston and preparation method and application thereof

A technology of composite materials and pistons, which is applied in the direction of pistons, cylindrical pistons, plungers, etc., can solve the problems of high thermal expansion coefficient of aluminum alloy pistons, difficulty in obtaining a large increase, and high density of cast steel pistons, so as to improve mechanical strength , good dimensional stability, and high mechanical strength at high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

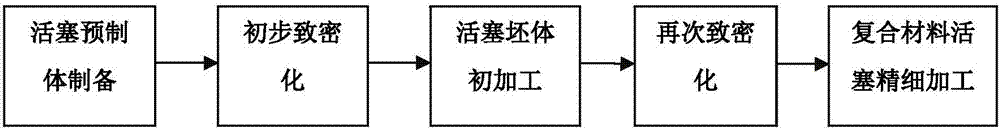

[0031] The invention provides a method for preparing a composite material piston, comprising the following steps:

[0032] S1: The piston preform is prepared by carbon fiber or polyacrylonitrile-based pre-oxidized wire; the initial density of the piston preform is 0.45-0.6g / cm 3 , the piston prefabricated body is formed by three-dimensional needling or four-step three-dimensional weaving.

[0033] S2: Preliminary densification treatment of the piston preform by chemical vapor infiltration method and / or precursor impregnation cracking method, and further densification treatment of the obtained product by chemical vapor phase infiltration method to obtain a density of 1.74-2.0g / cm 3 Composite pistons;

[0034] Step S2 is specifically: using chemical vapor infiltration method to deposit interfacial phase on the surface of the piston preform, including using natural gas and hydrogen as reaction gases, the flow ratio of natural gas and hydrogen is 2:1-3:1, and the flow rate of nat...

Embodiment 1

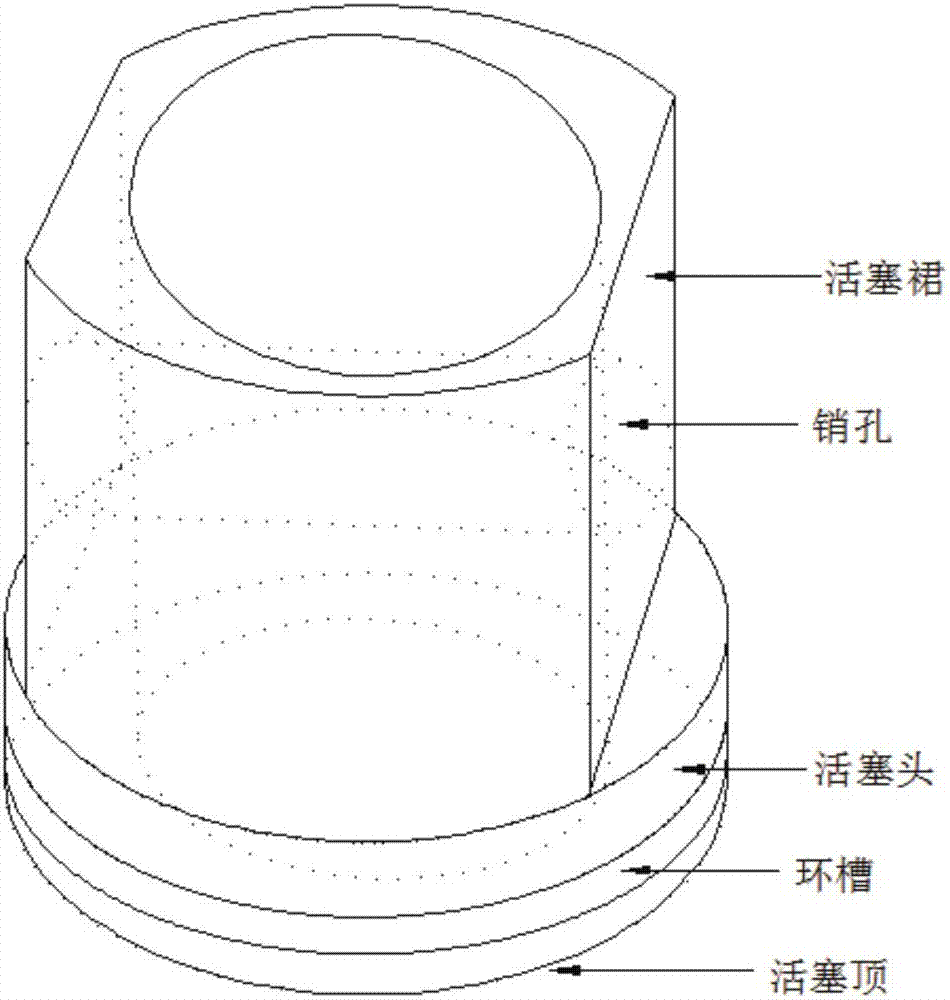

[0041] Imported T700 carbon fiber is prepared by three-dimensional acupuncture method to obtain an initial density of 0.45g / cm 3 The piston prefab, the size of the prefab is The structure of the piston preform is as follows figure 2 shown. The interfacial phase is deposited on the surface of the piston preform by chemical vapor infiltration, including natural gas and hydrogen as reaction gases, wherein the flow ratio of natural gas and hydrogen is 2:1, and the flow rate of natural gas is 0.6m 3 / h, the pressure is 2kPa, the power is 20kw, the temperature is raised to 1070°C at a heating rate of 300°C / h and kept for 25h, and the thickness of the interface layer reaches 400nm after densification; then the obtained material is treated by the precursor impregnation cracking method, Including dissolving polycarbosilane in xylene at 25°C for 6 hours to obtain polycarbosilane xylene solution, the mass ratio of polycarbosilane and xylene is 1:3, placing the obtained material in an...

Embodiment 2

[0043] The domestic polyacrylonitrile-based pre-oxidized yarn was selected and prepared by four-step three-dimensional weaving to obtain an initial density of 0.6g / cm 3 The piston prefab, the size of the prefab is The structure of the piston preform is as follows figure 2 shown. Preliminary densification of the piston preform by chemical vapor infiltration method, including using natural gas and propane as the reaction gas and hydrogen as the carrier gas, wherein the flow ratio of natural gas and propane is 6:1, the infiltration pressure is 8kPa, and the temperature is 1100°C , the infiltration time is 60h, and the density is 1.2g / cm 3 Composite pistons made of composite materials, the preliminary densified products are preliminarily machined to form a piston embryonic structure; the piston embryonic structure is completely densified by chemical vapor infiltration, including natural gas and propane as reaction gases, and hydrogen as a carrier. Gas, wherein the flow ratio ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com