Silicon tiny powder surface treating and modifying method, epoxy resin combination and preparation method thereof

A surface treatment, epoxy resin technology, applied in the field of integrated circuit packaging material preparation, can solve the problems of poor comprehensive EMC performance, decreased EMC fluidity, and insignificant improvement in fluidity, and achieves increased filling amount, improved mechanical properties and thermal conductivity. properties, and the effect of reducing water absorption and coefficient of thermal expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] An embodiment of the present invention provides a method for modifying the surface of silicon micropowder by plasma treatment, which can prepare plasma-coated modified silicon micropowder. The silicon micropowder can be used to manufacture epoxy resin compositions for packaging large-scale integrated circuits. The method includes:

[0025] Under the vacuum condition of 50Pa~100Pa, use radio frequency plasma discharge with radio frequency of 13.56MHz to polymerize any monomer or any mixture of monomers in pyrrole, 1,3-diaminopropane, acrylic acid and urea Coating on the surface of silicon micropowder to obtain modified silicon micropowder. The discharge power of the RF plasma is 100-120W, and the discharge time is 60-80s.

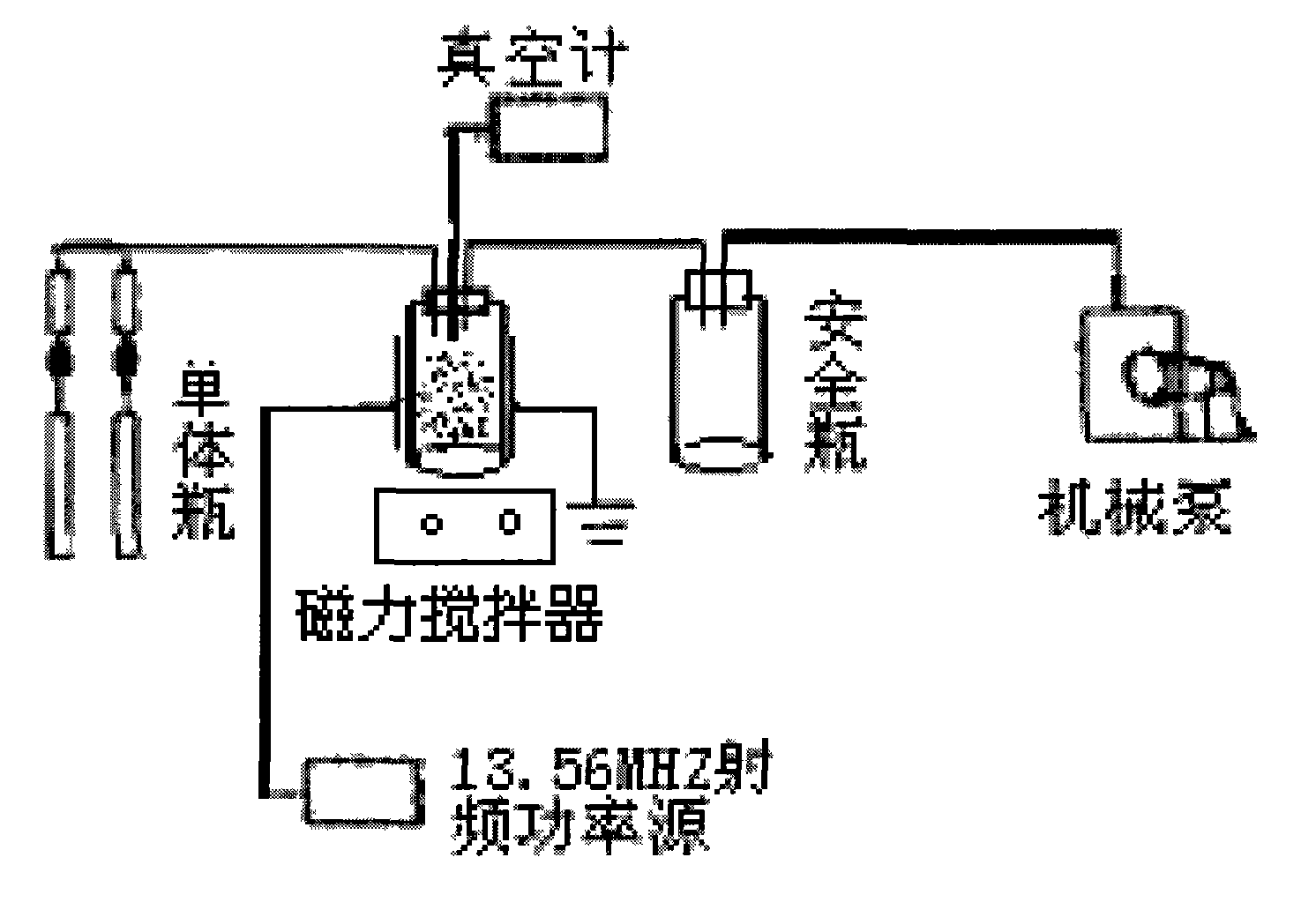

[0026] Combine below figure 1 Described reaction device, the above-mentioned modification method to silicon micropowder surface treatment is described further:

[0027] The silicon micropowder can be cleaned first: specifically, the surface cleaning...

Embodiment 2

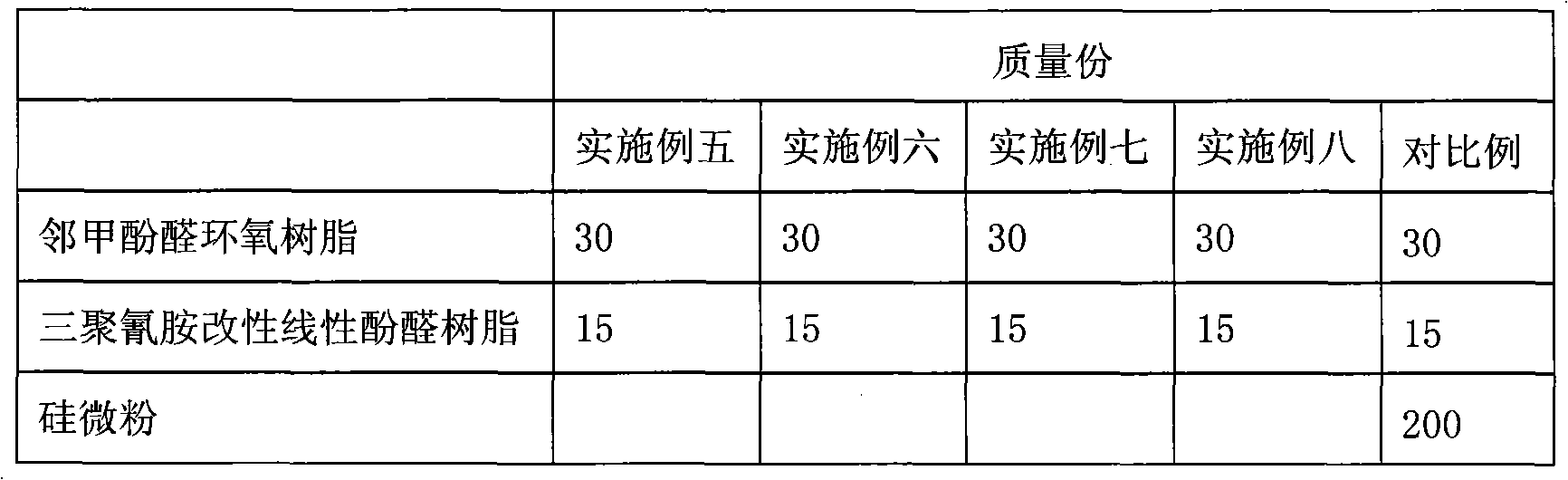

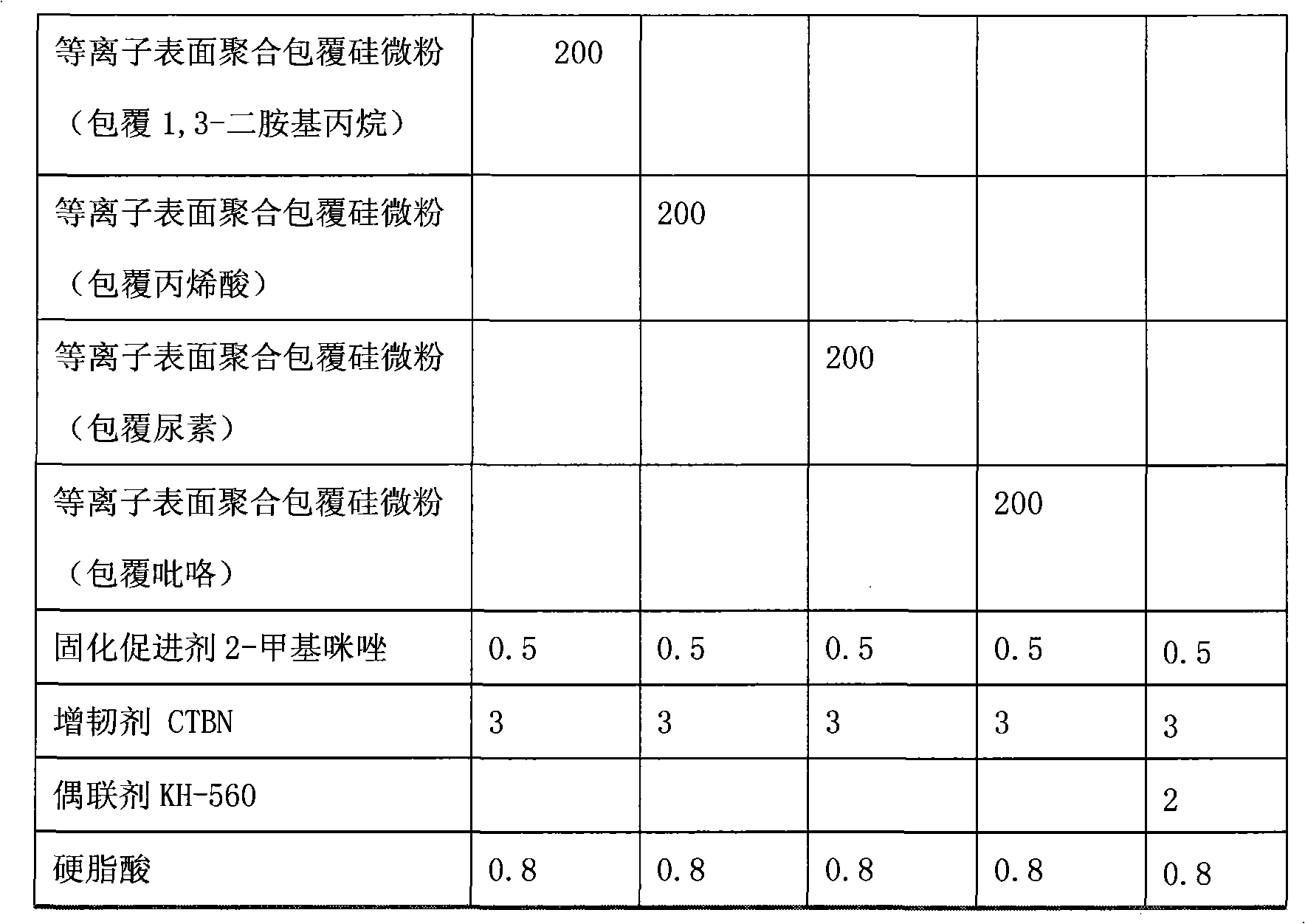

[0032] This embodiment 2 provides an epoxy resin composition, specifically using the silicon micropowder prepared in the above embodiment 1 as a raw material, the prepared epoxy resin composition can be used for large-scale integrated circuit packaging, the epoxy resin composition include:

[0033] Get each raw material by following mass ratio:

[0034] 10-30 parts by mass of epoxy resin

[0035] Curing Accelerator 5-25 parts by mass

[0036] 100-150 parts by mass of the modified silicon micropowder prepared by any one of the above-mentioned claims 1-7

[0037] Imidazole curing accelerator 0.1-2 parts by mass

[0038] Toughener 2~10 parts by mass

[0039] Lubricant 0.5-5 parts by mass

[0040] The epoxy resin composition is obtained by mixing silicon micropowder with epoxy resin, curing agent, imidazole curing accelerator, lubricant, toughening agent, etc., kneading, pulverizing and degaussing.

[0041] In the above epoxy resin composition, the epoxy resin is o-cresol no...

Embodiment 3

[0047] This embodiment provides a method for surface treatment and modification of silicon micropowder, which can be figure 1 Shown reaction unit, this method is specifically as follows:

[0048] In the reaction bottle of reaction device, add 10g spherical microsilica powder (particle diameter D 50 = 10 microns), pump the reaction bottle to a vacuum of 50Pa ~ 60Pa, open the argon Ar inlet valve to feed argon Ar into the reaction bottle, and keep the vacuum in the reaction bottle at 50Pa ~ 50Pa by adjusting the Ar inlet valve. 60Pa, start the discharge of the spherical silicon micropowder, stop the discharge after 5min, turn off the vacuum pump and the argon Ar inlet valve, let it into the atmosphere, return the reaction bottle of the reaction device to normal pressure, add 1g of 1,3-diamine propane monomer, and stir it evenly with a glass rod; re-evacuate the reaction bottle of the reaction device to a vacuum of 50Pa ~ 60Pa, open the argon Ar inlet valve to feed argon Ar, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com