Dimer acid epoxy resin composition for chip packaging, application of dimer acid epoxy resin composition and cutting method of chip

A technology of dimer acid epoxy resin and chip packaging, which is applied in semiconductor/solid-state device components, electric solid-state devices, semiconductor devices, etc., and can solve the problem of affecting the packaging performance of semiconductor chips, easily generating debris, and warping of protective glue, etc. problems, to achieve the effect of reducing the mismatch of overall temperature expansion characteristics, preventing oxidation of solder joints, and increasing cushioning performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

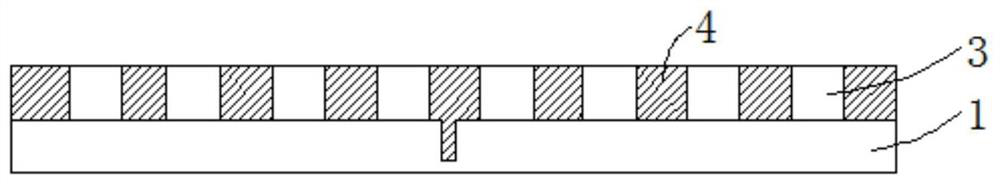

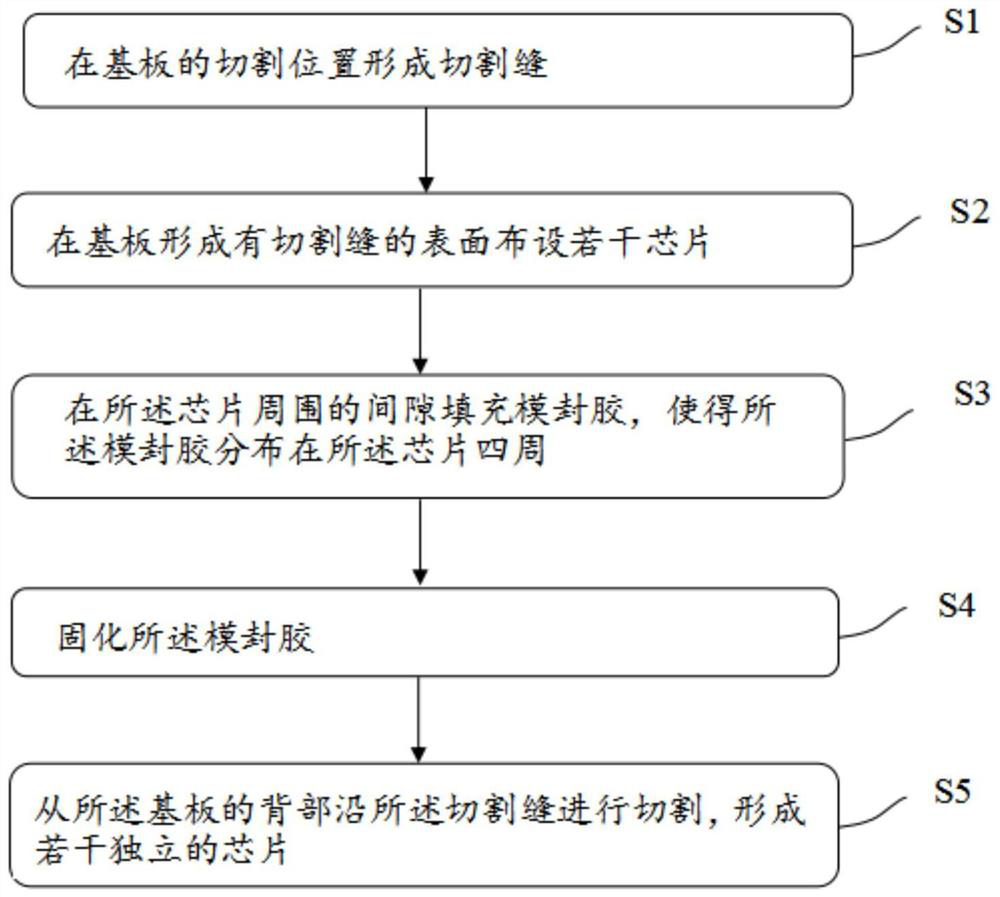

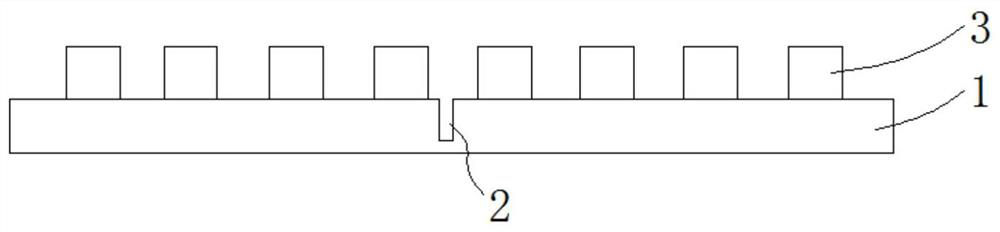

[0065] The present application also provides a molding compound for chip packaging, wherein the raw material of the molding compound includes the above dimer acid epoxy resin composition. The preparation method of the mold sealant comprises: mixing each component epoxy resin, curing agent, curing accelerator, inorganic filler, colorant and coupling agent according to parts by mass, and grinding it with a three-roller mill to a jelly-like substance, and vacuum-removing it. Bubble, that is, the mold sealant.

[0066] In some embodiments of the present application, the molding compound has a low thermal expansion coefficient, which can effectively reduce the impact caused by the mismatch of the overall temperature expansion characteristics between the chip and the substrate or the external force of chip cutting. Specifically, the viscosity of the molding compound ranges from 25 Pa·s to 50 Pa·s. Exemplarily, the viscosity of the molding compound is 25 Pa·s, 30 Pa·s, 35 Pa·s or 40...

Embodiment

[0085] Mix the components (epoxy resin, curing agent, curing accelerator, inorganic filler, colorant, coupling agent) according to the composition table shown in Table 1, and grind them with a three-roll mill to a jelly-like substance, which is then degassed by vacuum. , that is, a molding compound with chip edge protection is obtained.

[0086] The test method for the thermal expansion coefficient CTE1 is: after curing the liquid molding compound at 150°C / 1h, prepare a sample that meets the requirements of the standard ASTM E831-2019, and test the thermal expansion coefficient of the sample.

[0087] The test method for warpage is as follows: apply the molding glue evenly on the glass slide, bake at 130°C for 1 hour, and take it out after natural cooling. Remove the residual resin around the glass slide, fix one side of the glass slide, measure the distance that the glass slide is lifted with a ruler, and this distance is recorded as warpage.

[0088] The test method of hard...

Embodiment 2

[0095]It can be seen from the comparison of Example 2 and Comparative Examples 1-3 that Example 2 of the present application adopts the compounding of dimer acid epoxy resin and silicon-containing epoxy resin, wherein the consumption of dimer acid epoxy resin is 15 parts by weight, containing The amount of silicone epoxy resin used is 10 parts by weight, the warpage is much lower than that of Comparative Examples 2 and 3, the coefficient of thermal expansion is much lower than that of Comparative Examples 1 and 2, and the hardness is also much higher than that of Comparative Examples 1 and 3. And the silicon-containing epoxy resin in Comparative Example 1 is not compounded with dimer acid epoxy resin, and its curing agent and curing accelerator are different from the materials and consumption of Example 2, and the consumption of silicon dioxide is higher than that of Comparative Example 1. It can be clearly seen that its thermal expansion coefficient is much higher than that of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com