Modified starch/polyacrylamide textile slurry composition and preparation thereof

A polyacrylamide and modified starch technology, applied in the field of textile size, can solve the problems of desizing waste liquid environmental pollution, change the hardness and brittleness of starch size film, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

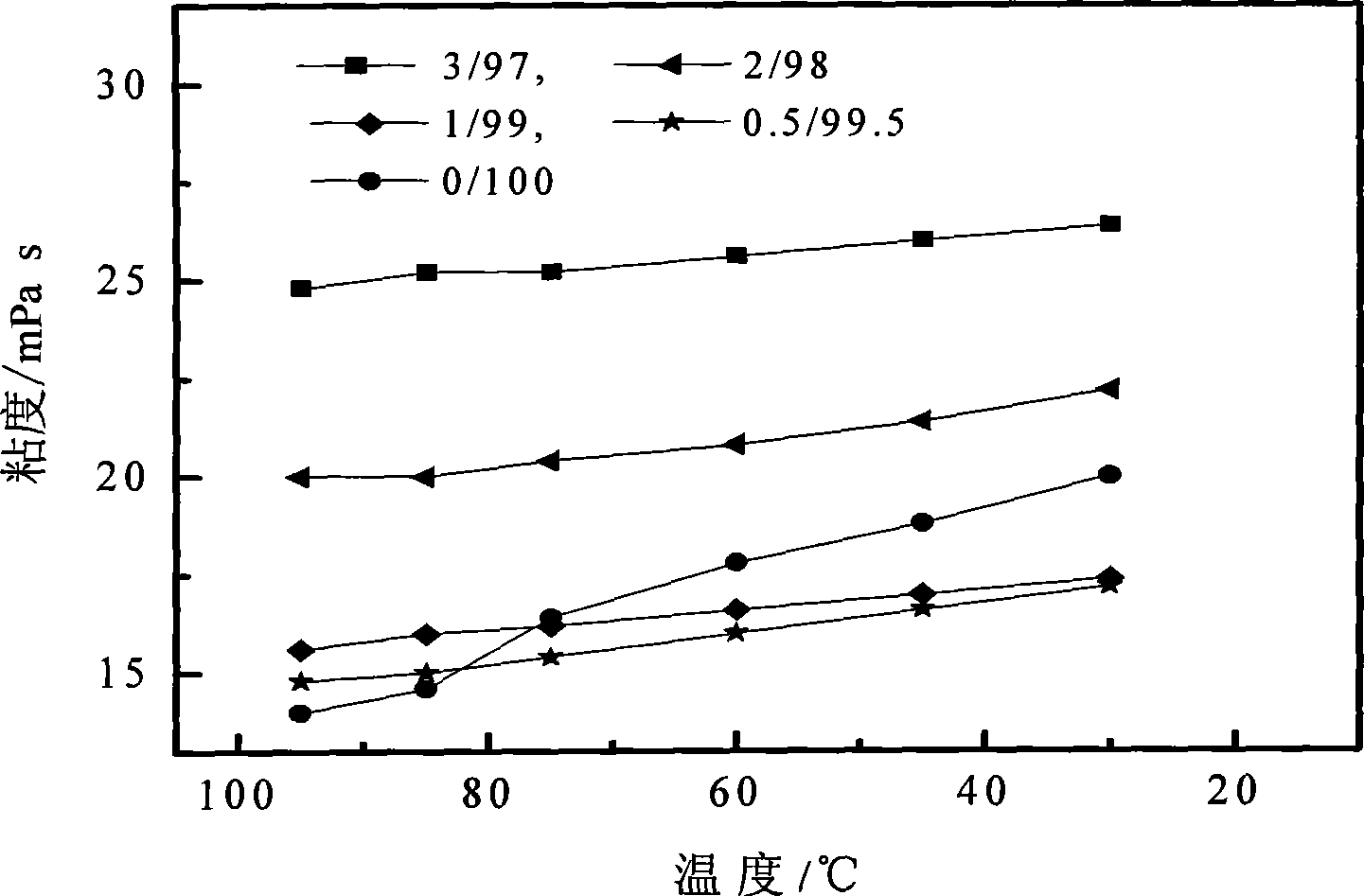

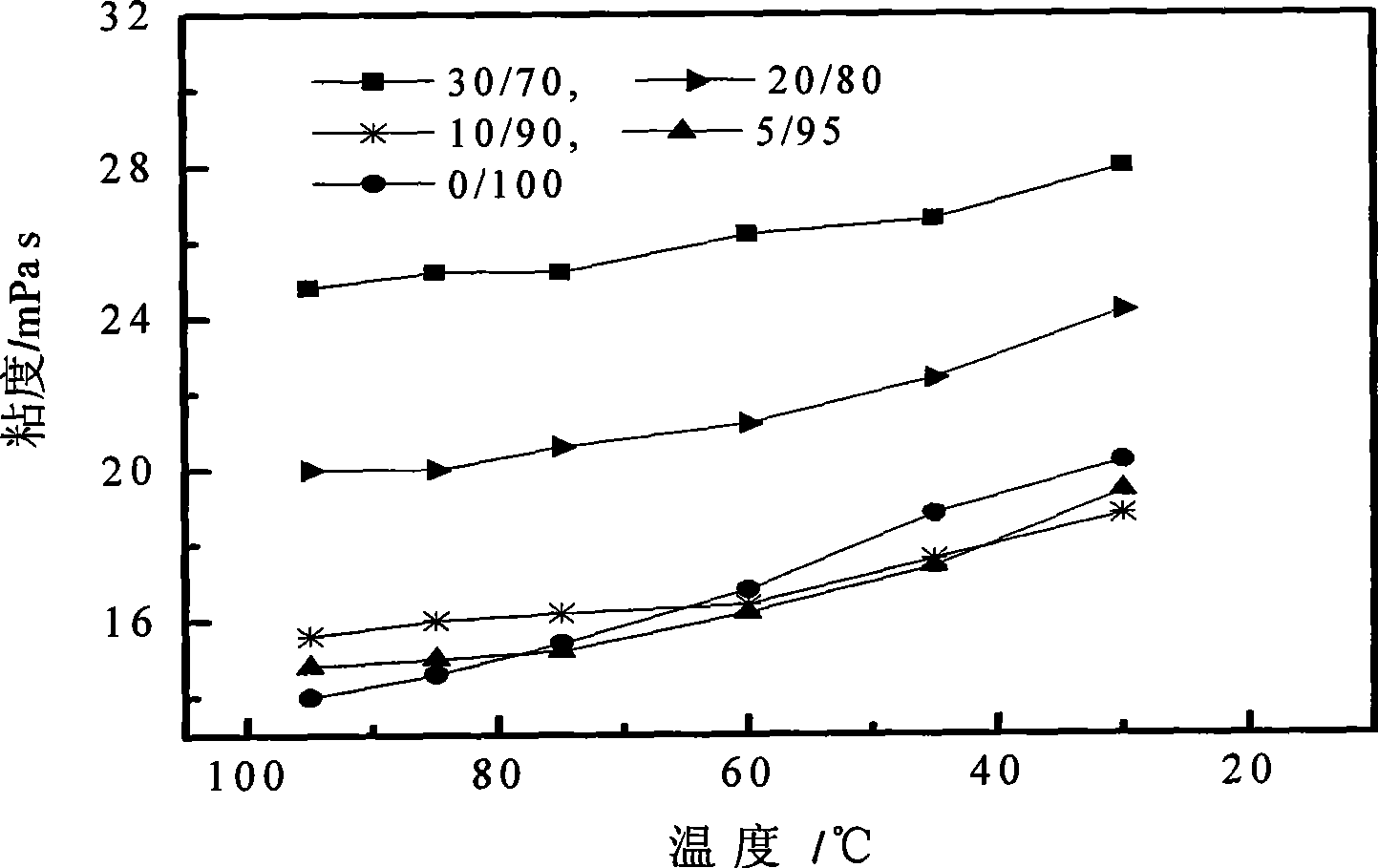

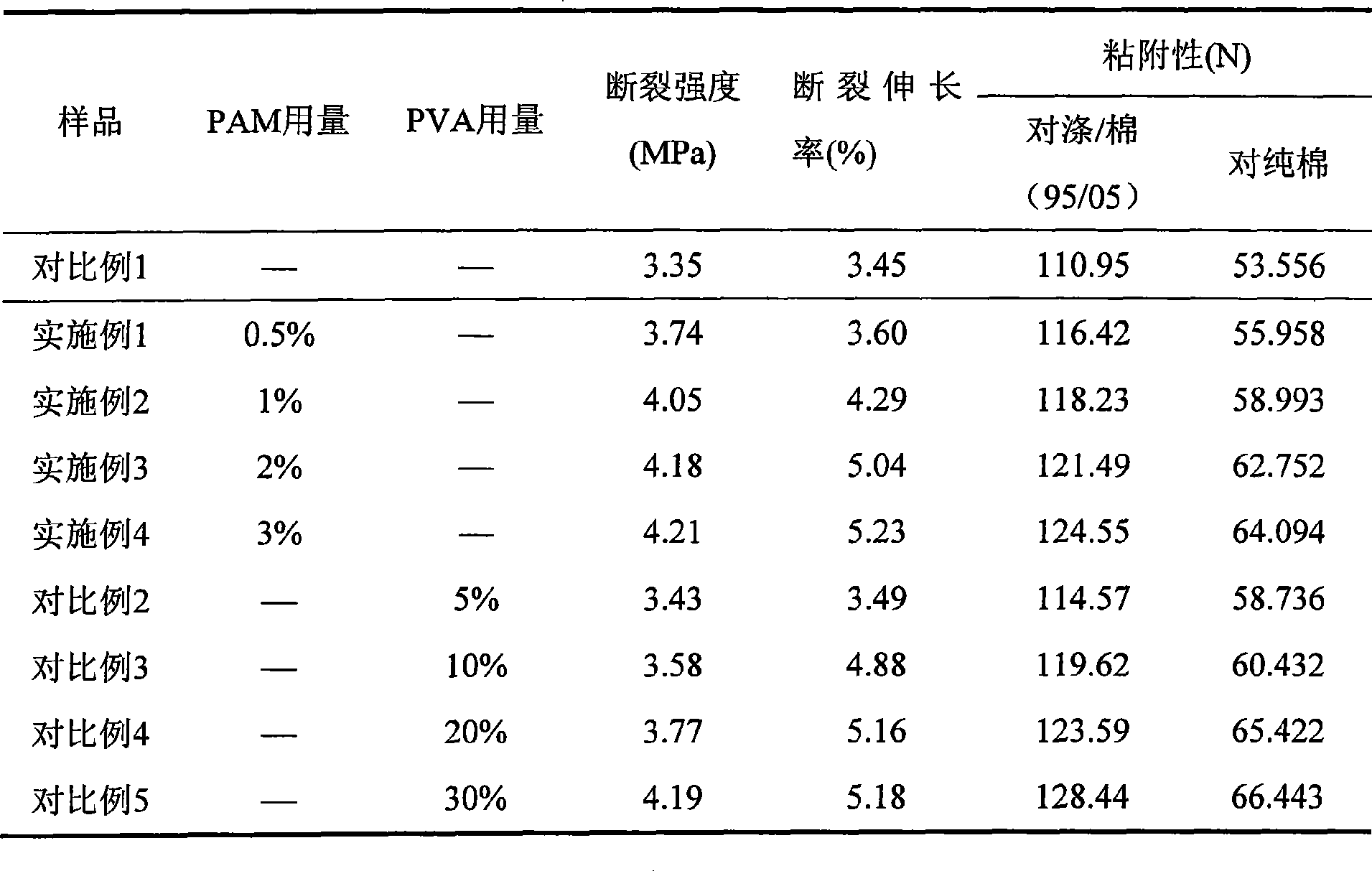

[0041] 99.5 parts of oxidized tapioca starch and 0.5 part of non-ionic PAM with a molecular weight of 18 million are physically mixed in a dry powder state, 1667 parts of deionized water are added, stirred evenly, heated and boiled and then incubated for 1.5 hours to obtain oxidized tapioca starch / PAM textile size composition, the size solid content is 6%.

[0042] Determination of slurry viscosity and mechanical properties of the size film are shown in Table 1.

Embodiment 2

[0044] Adopt 99 parts of oxidized tapioca starch, molecular weight is 18 million non-ionic PAM1 parts, mix uniformly, add 1667 parts of deionized water, stir well, after heating and boiling, keep warm for 1.5 hours, make oxidized tapioca starch / PAM textile size composition, The solid content of the slurry is 6%.

[0045]Determination of slurry viscosity and mechanical properties of the size film are shown in Table 1.

Embodiment 3

[0047] Adopt 98 parts of oxidized tapioca starch, molecular weight is 18 million non-ionic PAM2 parts, mix well, add 1667 parts of deionized water, stir well, after heating and boiling, keep warm for 1.5 hours, make oxidized tapioca starch / PAM textile size composition, The solid content of the slurry is 6%.

[0048] Determination of slurry viscosity and mechanical properties of the size film are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com